i01889424

Product

Information

Section

General

Information

Welding

on

Engines

with

Electronic

Controls

NOTICE

Proper welding procedures are necessary in order to

avoid damage to the engine's ECM, sensors, and as-

sociated components. When possible, remove the

component from the unit and then weld the compo-

nent. If removal of the component is not possible, the

following procedure must be followed when you weld

with a unit that is equipped with an Electronic Engine.

The following procedure is considered to be the saf-

est procedure to weld a component. This procedure

should provide a minimum risk of damage to elec-

tronic components.

NOTICE

Do not ground the welder to electrical components

such as the ECM or sensors. Improper grounding

can cause damage to the drive train bearings, hy-

draulic components, electrical components, and oth-

er components.

Clamp the ground cable from the welder to the com-

ponent that will be welded. Place the clamp as close

as possible to the weld. This will help reduce the pos-

sibility of damage.

1.

Stop the engine. Turn the switched power to the

OFF position.

2.

Disconnect the negative battery cable from the

battery. If a battery disconnect switch is provided,

open the switch.

3.

Disconnect the J1/P1 connectors from the ECM.

Move the harness to a position that will not allow

the harness to accidentally move back and make

contact with any of the ECM pins.

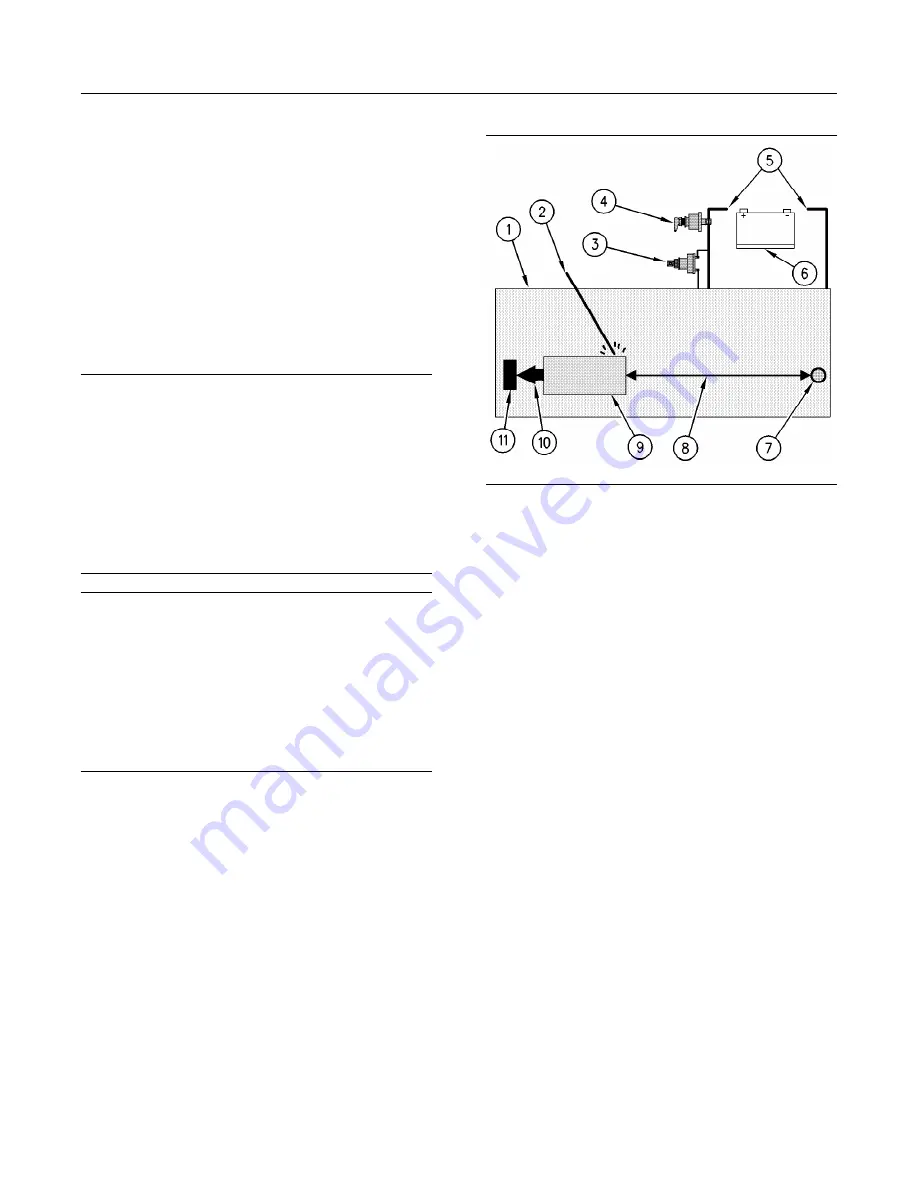

Illustration 17

g00765012

Use the example above. The current flow from the

welder to the ground clamp of the welder will not

cause damage to any associated components.

(1) Engine

(2) Welding rod

(3) Keyswitch in the OFF position

(4) Battery disconnect switch in the open position

(5) Disconnected battery cables

(6) Battery

(7) Electrical/Electronic component

(8) Maximum distance between the component that is being

welded and any electrical/electronic component

(9) The component that is being welded

(10) Current path of the welder

(11) Ground clamp for the welder

4.

Connect the welding ground cable directly to the

part that will be welded. Place the ground cable as

close as possible to the weld in order to reduce the

possibility of welding current damage to bearings,

hydraulic components, electrical components, and

ground straps.

Note:

If electrical/electronic components are used as

a ground for the welder, or electrical/electronic

components are located between the welder ground

and the weld, current flow from the welder could

severely damage the component.

5.

Protect the wiring harness from welding debris and

spatter.

6.

Use standard welding practices to weld the

materials.

20

SEBU8119-04