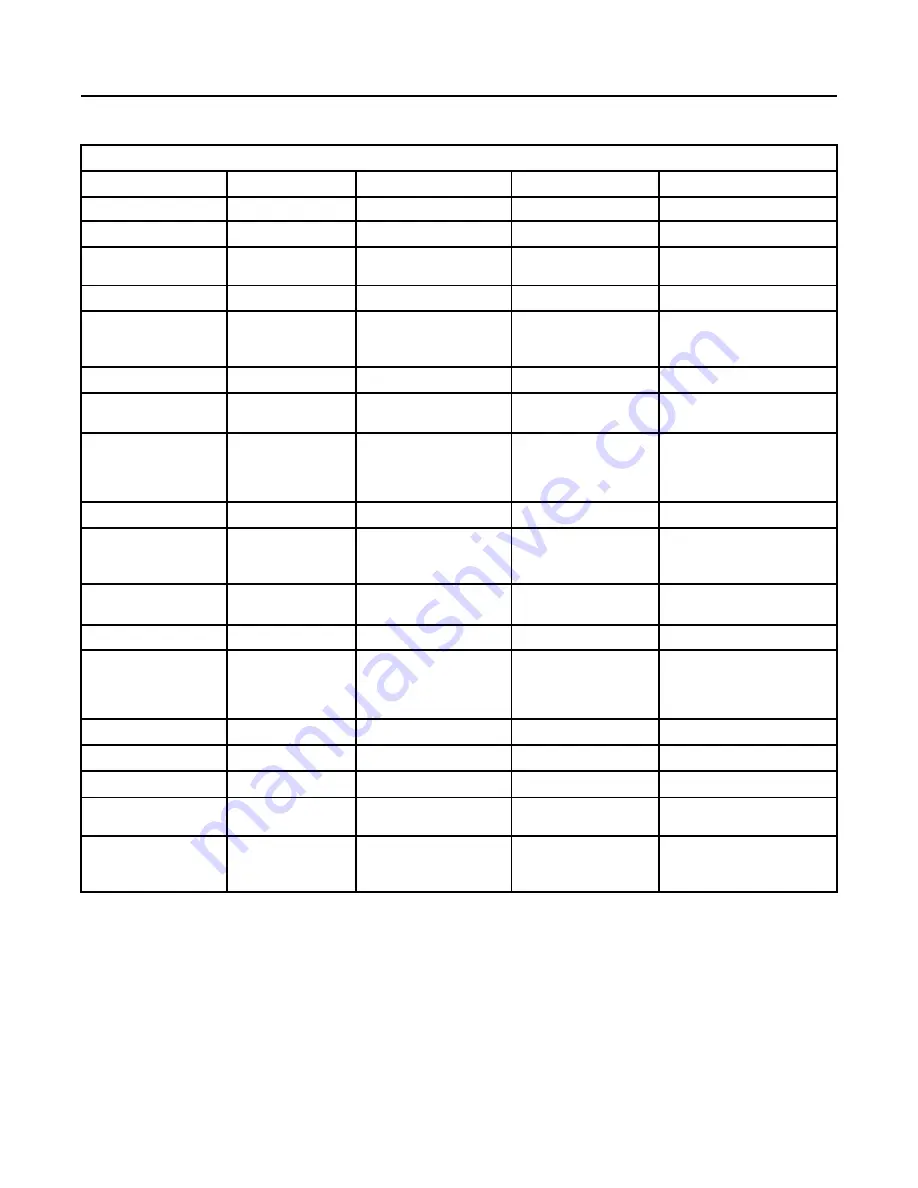

Table 9

Perkins Specification for Distillate Diesel Fuel

Property

UNITS

Requirements

“ASTM”Test

“ISO”Test

Aromatics

%Volume

35% maximum

D1319

“ISO”3837

Ash

%Weight

0.01% maximum

D482

“ISO”6245

Carbon Residue on 10%

Bottoms

%Weight

0.35% maximum

D524

“ISO”4262

Cetane Number

-

40 minimum

D613/D6890

“ISO”5165

Cloud Point

°C

The cloud point must not ex-

ceed the lowest expected

ambient temperature.

D2500

“ISO”3015

Copper Strip Corrosion

-

No. 3 maximum

D130

“ISO”2160

Density at 15 °C (59 °F)

Kg / M

3

801 minimum and 876

maximum

No equivalent test

“ISO 3675 ”“ISO 12185”

Distillation

°C

10% at 282 °C (539.6 °F)

maximum

90% at 360 °C (680 °F)

maximum

D86

“ISO”3405

Flash Point

°C

legal limit

D93

“ISO”2719

Thermal Stability

-

Minimum of 80% reflec-

tance after aging for 180 mi-

nutes at 150 °C (302 °F)

D6468

No equivalent test

Pour Point

°C

6 °C (42.8 °F) minimum be-

low ambient temperature

D97

“ISO”3016

Sulfur

%mass

1% maximum

D5453/D26222

“ISO 20846 ”“ISO 20884”

Kinematic Viscosity

“MM”

2

“/S (cSt)”

The viscosity of the fuel that

is delivered to the fuel injec-

tion pump. “1.4 minimum/

4.5 maximum”

D445

“ISO”3405

Water and sediment

% weight

0.1% maximum

D1796

“ISO”3734

Water

% weight

0.1% maximum

D1744

No equivalent test

Sediment

% weight

0.05% maximum

D473

“ISO”3735

Gums and Resins

mg/100mL

10 mg per 100 mL

maximum

D381

“ISO”6246

Lubricity corrected wear

scar diameter at 60 °C

(140 °F).

mm

0.52 maximum

D6079

“ISO”12156-1

(1)

This specification includes the requirements for Ultra Low Sulfur Diesel (ULSD). ULSD fuel will have ≤ 15 ppm (0.0015%) sulfur. Refer to

“ASTM D5453”, “ASTM D2622”, or “ISO 20846, ISO 20884” test methods. This specification includes the requirements for Low Sulfur Diesel

(LSD). LSD fuel will have ≤500 ppm (0.05%) sulfur. Refer to following:“ASTM 5453, ASTM D2622”, “ISO 20846” and “ISO 20884 test

methods”.

(2)

A fuel with a higher cetane number is recommended in order to operate at a higher altitude or in cold weather.

(3)

“Via standards tables, the equivalent API gravity for the minimum density of 801 kg / m

3

(kilograms per cubic meter) is 45 and for the maxi-

mum density of 876 kg / m

3

is 30”.

(4)

Regional regulations, national regulations or international regulations can require a fuel with a specific sulfur limit. Consult all applicable regu-

lations before selecting a fuel for a given engine application. Perkins fuel systems and engine components can operate on high sulfur fuels.

Fuel sulfur levels affect exhaust emissions. High sulfur fuels also increase the potential for corrosion of internal components. Fuel sulfur lev-

els above 0.5% may significantly shorten the oil change interval. For additional information, refer to this manual, “Fluid recommendations

(General lubricant Information)”.

(continued)

56

SEBU8119-04