SEBU8337

61

Maintenance Section

Crankshaft Vibration Damper - Inspect

i02573905

Crankshaft Vibration Damper

- Inspect

Damage to the crankshaft vibration damper or failure

of the crankshaft vibration damper can increase

torsional vibrations. This can result in damage to

the crankshaft and to other engine components. A

damper that is damaged can cause excessive gear

train noise at variable points in the speed range.

The damper is mounted to the crankshaft which is

located behind the belt guard on the front of the

engine.

Visconic Damper

The visconic damper has a weight that is located

inside a

fl

uid

fi

lled case. The weight moves in the

case in order to limit torsional vibration.

Inspect the damper for evidence of

fl

uid leaks. If

a

fl

uid leak is found, determine the type of

fl

uid.

The

fl

uid in the damper is silicone. Silicone has the

following characteristics: transparent, viscous, and

smooth.

If the

fl

uid leak is oil, inspect the crankshaft seals for

leaks. If a leak is observed, replace the crankshaft

seals.

Inspect the damper and repair or replace the damper

for any of the following reasons:

•

The damper is dented, cracked, or leaking.

•

The paint on the damper is discolored from heat.

•

The engine has had a failure because of a broken

crankshaft.

•

Analysis of the oil has revealed that the front main

bearing is badly worn.

•

There is a large amount of gear train wear that is

not caused by a lack of oil.

•

The temperature of the damper

fl

uid is too high.

Refer to the Service Manual or consult your Perkins

distributor for information about damper replacement.

i02151646

Driven Equipment - Check

Refer to the OEM speci

fi

cations for more information

on the following maintenance recommendations for

the driven equipment:

•

Inspection

•

Adjustment

•

Lubrication

•

Other maintenance recommendations

Perform any maintenance for the driven equipment

which is recommended by the OEM.

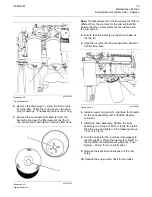

i02784833

Electronic Unit Injector -

Inspect/Adjust

Be sure the engine cannot be started while this

maintenance is being performed. To prevent pos-

sible injury, do not use the starting motor to turn

the

fl

ywheel.

Hot engine components can cause burns. Allow

additional time for the engine to cool before mea-

suring/adjusting the unit injectors.

The electronic unit injectors use high voltage. Dis-

connect the unit injector enable circuit connector

in order to prevent personal injury. Do not come

in contact with the injector terminals while the en-

gine is running.

The operation of Perkins engines with improper

adjustments of the electronic unit injector can reduce

engine ef

fi

ciency. This reduced ef

fi

ciency could result

in excessive fuel usage and/or shortened engine

component life.

Only quali

fi

ed service personnel should perform

this maintenance. Refer to the following topics

for your engine for the correct procedure: Refer

to the Systems Operation, Testing and Adjusting,

“Electronic Unit Injector - Test” for the test procedure,

and Systems Operation, Testing and Adjusting,

“Electronic Unit Injector - Adjust” for the correct

procedure for adjusting the injectors.