6.

Install hose (6) with clip (5), tighten clip securely.

i07819538

Engine

Mounts

-

Inspect

Note:

The

engine

mounts

may

not

have

been

supplied

by

Perkins.

Refer

to

the

Original

Equipment

Manufacturer

(OEM)

information

for

further

details

on

the

engine

mounts

and

the

correct

bolt

torque.

Inspect

the

engine

mounts

for

deterioration

and

for

correct

bolt

torque.

Excessive

engine

vibration

can

be

caused

by

the

following

conditions:

• Incorrect mounting of the engine

• Deterioration of the engine mounts

• Loose engine mounts

Any engine mount that shows deterioration should be

replaced. Refer to the OEM information for the

recommended torques.

When the engine mounts are supplied by Perkins the

maintenance procedure will be supplied in the

Disassembly and Assembly manual for your engine.

i07460055

Engine

Oil

Level

-

Check

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

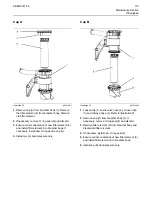

Illustration 84

g02455244

Typical installation of the oil level gauge

(1) Oil filler cap

(2) Oil level gauge

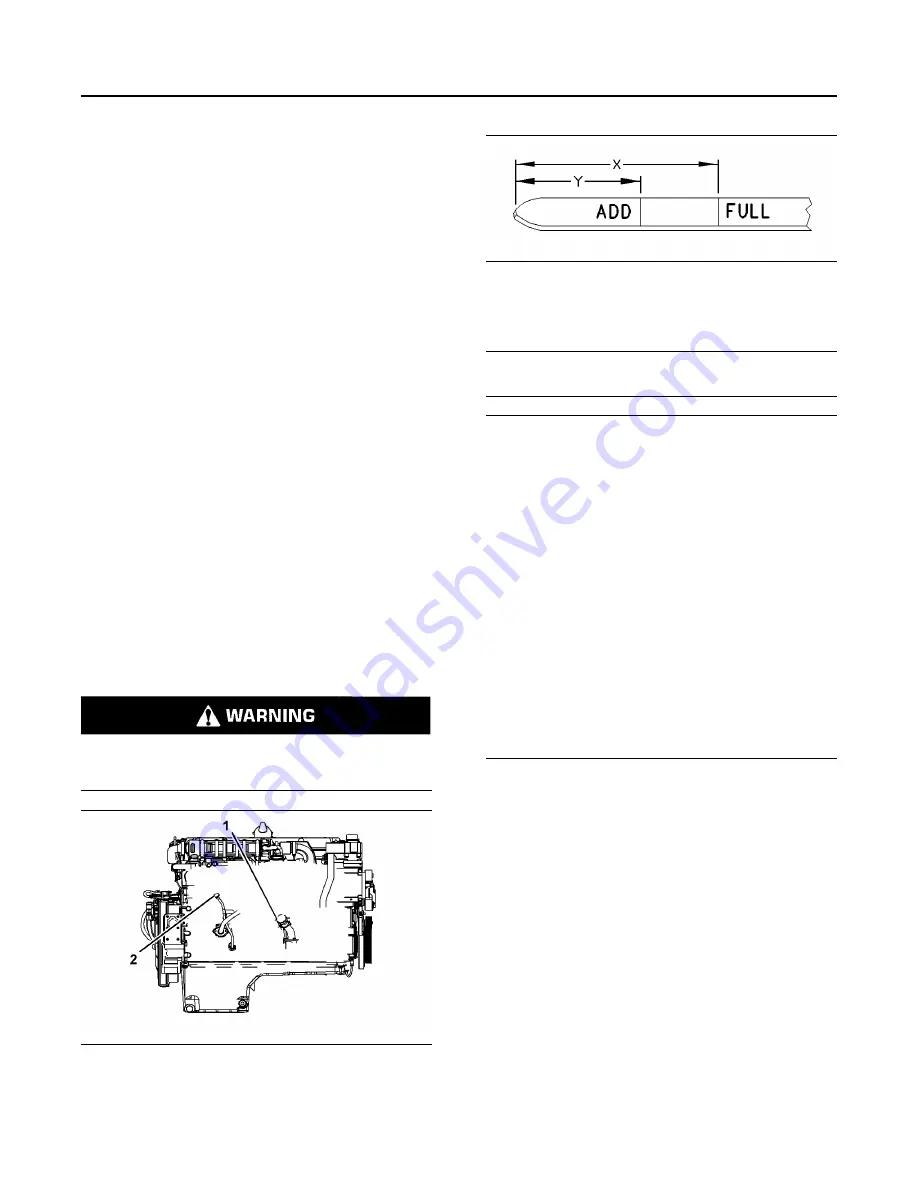

Illustration 85

g00110310

Partial view of the oil level gauge

(Y)

“

ADD

”

mark

(X)

“

FULL

”

mark

NOTICE

Perform this maintenance with the engine stopped.

NOTICE

Engine damage can occur if the crankcase is filled

above the

“

FULL

”

mark on the oil level gauge

(dipstick).

An overfull crankcase can cause the crankshaft to dip

into the oil. This will reduce the power that is devel-

oped and also force air bubbles into the oil. These

bubbles (foam) can cause the following problems: re-

duction of the oil's ability to lubricate, reduction of oil

pressure, inadequate cooling, oil blowing out of the

crankcase breathers and excessive oil consumption.

Excessive oil consumption will cause deposits to form

on the pistons and in the combustion chamber. De-

posits in the combustion chamber lead to the follow-

ing problems: guttering of the valves, packing of

carbon under the piston rings and wear of the cylin-

der liner.

If the oil level is above the

“

FULL

”

mark on the oil lev-

el gauge, drain some of the oil immediately.

1.

Remove the oil filler cap and check the oil level.

Maintain the oil level between the

“

ADD

”

mark (Y)

and the

“

FULL

”

mark (X) on the oil level gauge (1).

Do not fill the crankcase above

“

FULL

”

mark (X).

2.

To choose the correct type of oil for this engine,

refer to this Operation and Maintenance Manual,

“Fluid Recommendations”.

3.

Clean the oil filler cap. Install the oil filler cap.

4.

Record the amount of oil that is added. For the

next oil sample and analysis, include the total

amount of oil that has been added since the

previous sample. Recording this information helps

to provide the most accurate oil analysis.

SEBU9071-06

105