Chapter 2

TPD 1399E

Page 6

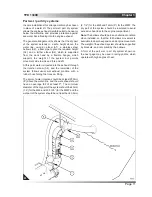

Part finished shafts

Where the precise shaft length can not be determined

until the engine has been fitted in the boat, propeller

shafts are sometimes supplied with excess length, to be

completed locally.

In these cases a clamp type coupling (A) should be used,

and it is not necessary to machine a shoulder on the shaft

end to take forward thrust. It is good practice however

to use one of the methods described above to provide a

safeguard against loss of the shaft when going astern.

Flexible couplings

Elasticity may be incorporated in the connection between

the gearbox output flange and the propeller shaft by

means of a flexible coupling (

B1). This type of coupling

is not intended for use with continuous misalignment, but

will cater for momentary deflections, due for example

to the effect of shock loadings on the anti-vibration

mounts supporting the engine. The flexible coupling is

sandwiched between the gearbox output flange and the

shaft coupling.

Couplings can be supplied to suit most of the marine

transmissions that may be specified with the engine.

Summary of Contents for M65

Page 1: ... Installation Manual GB Part No TPD 1399E M65 M85T ...

Page 2: ......

Page 4: ...TPD1399E ...

Page 20: ...Chapter 4 TPD 1399E Page 14 ...

Page 26: ...Chapter 6 TPD 1399E Page 20 ...

Page 28: ...Chapter 7 TPD 1399E Page 22 ...

Page 33: ...TPD 1399E Chapter 7 Page 27 ...

Page 34: ...Chapter 7 TPD 1399E Page 28 ...

Page 38: ...Chapter 7 TPD 1399E Page 32 ...

Page 40: ...Chapter 8 TPD 1399E Page 34 ...

Page 44: ...Chapter 9 TPD 1399E Page 38 ...

Page 46: ...Chapter 10 TPD 1399E Page 38 ...

Page 52: ...Chapter 11 TPD 1399E Page 44 ...