Chapter 5

TPD 1399E

Page 16

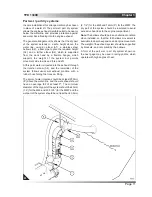

Keel cooling system

The M65 and M85T may be purchased in a form

suitable for keel cooling. The engine connections

provided for the cooler are to suit 32mm outside

diameter rigid pipe, as shown in (A) and (B). The

connection for the flow to the keel cooler is shown at

(B1) and the return at (A1). The design data for the

keel cooler is shown in the table below.

M65

M85T

Heat rejection

at rated power

40 kW (2300

Btu/min)

51kW (2908

Btu/min)

Design value for

the temperature

of the water

returning from

the keel cooler.

60

O

C

60

O

C

Design value

for the water

flow through the

keel cooler.

90 litres/min (20

imp galls/min)

90 litres/min (20

imp galls/min)

The pipework between the engine and the cooler

should be as short and direct as is possible, but

should be sufficiently flexible to allow the engine to

move on its anti-vibration mounts.

The pipe layout should discourage the formation of air

locks, and venting points should be provided wherever

an air lock is likely to occur.

The keel cooling system should normally be filled

with a water/anti freeze mixture containing 50%

antifreeze, to ensure that the inhibitors included in the

antifreeze are present at a sufficient level to minimise

corrosion.

Note:

The illustrations show the connections on the

M65, but are the same on the M85T.

Summary of Contents for M65

Page 1: ... Installation Manual GB Part No TPD 1399E M65 M85T ...

Page 2: ......

Page 4: ...TPD1399E ...

Page 20: ...Chapter 4 TPD 1399E Page 14 ...

Page 26: ...Chapter 6 TPD 1399E Page 20 ...

Page 28: ...Chapter 7 TPD 1399E Page 22 ...

Page 33: ...TPD 1399E Chapter 7 Page 27 ...

Page 34: ...Chapter 7 TPD 1399E Page 28 ...

Page 38: ...Chapter 7 TPD 1399E Page 32 ...

Page 40: ...Chapter 8 TPD 1399E Page 34 ...

Page 44: ...Chapter 9 TPD 1399E Page 38 ...

Page 46: ...Chapter 10 TPD 1399E Page 38 ...

Page 52: ...Chapter 11 TPD 1399E Page 44 ...