S

amu

el

H

ea

th

DO

OR

PAT

EN

TS

AP

PL

IE

D

FO

R

PER

KO

POW

ERM

ATIC

C

LO

SI

N

G

SP

EE

D

+

–

E

S

amu

el

H

ea

th

DO

OR

PAT

ENT

S

APP

LIE

D F

OR

CLO

SIN

G

SPE

ED

+

–

C

E

D

D

PERK

O

POW

ERM

ATI

C

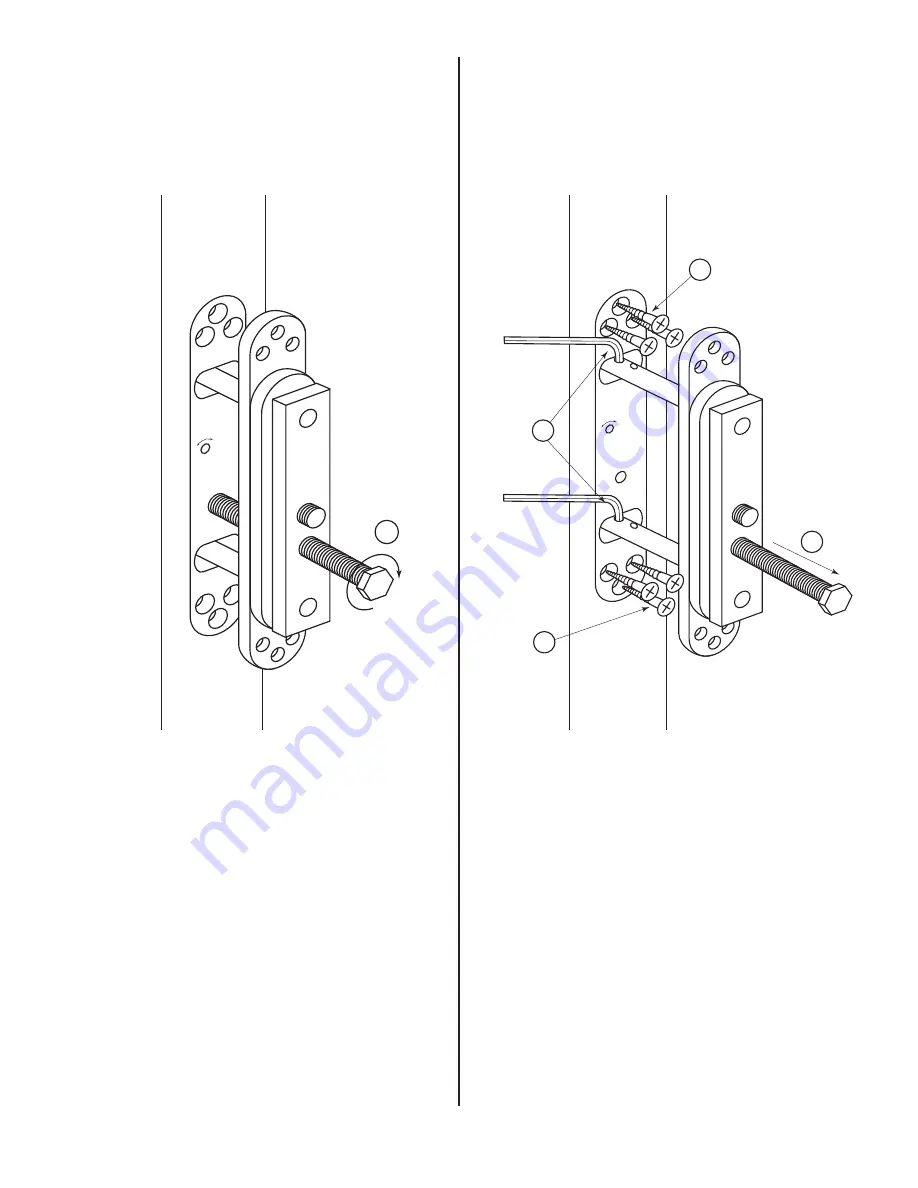

• Insert closer body into door.

• Insert extractor bolt (E) into

position and rotate clockwise

until holes in link rods appear.

• Generally for thicker doors

expose both holes on each rod.

INSTALLING CLOSER

5

• Insert the allen keys (C)

through both top and bottom

link rod holes.

B

Bo

otth

h a

alllle

en

n k

ke

ey

yss m

mu

usstt b

be

e

cco

orrrre

eccttlly

y llo

occa

atte

ed

d..

• Remove extractor bolt.

• Secure door plate to door with

six screws (D).

IIM

MP

PO

OR

RT

TA

AN

NT

T

W

Wiitth

h cco

om

mp

po

ossiitte

e d

do

oo

orrss a

an

nd

d d

do

oo

orr

lliin

niin

ng

gss iitt iiss e

esssse

en

nttiia

all tto

o d

drriillll p

piillo

ott

h

ho

olle

ess Ø

Ø

3

3

//

3

32

2

”

” ((2

2..5

5m

mm

m)) tto

o ssu

uiitt

ffiix

xiin

ng

g ssccrre

ew

wss..

6