© 2009

3

24” ADA-Compliant Series Operation / Installation Manual

PREPARING THE SPACE

Make sure the installation opening is properly prepared. Refer to

Figure 1 for space dimensions.

CAUTION

If unit is to be installed under a countertop, it is recommended

that the countertop be supported by a structure other than the

unit itself, to prevent damage to the countertop.

IMPORTANT:

For a cabinet door to operate properly, the door must

open a minimum of 100° (see Figure 1). Use a minimum 4-1/2” filler in

corner installations to ensure a 100° opening. Allow enough clearance

in front of the unit for full door swing or shelf pull-out.

IMPORTANT:

Make sure floor under unit is level with the surround-

ing finished floor. Protect a finished floor with plywood, cardboard or

some other suitable material before moving the unit into place. Failure

to do this may result in damage to the floor.

PREPARING ELECTRICAL CONNECTIONS

A 115 volt, 60Hz, 15 amp circuit breaker and electrical supply are

required. A separate circuit is recommended

Follow the National Electrical Code along with local codes and ordi-

nances when installing the receptacle.

All Perlick units come equipped with a NEMA 5-15P, 90° plug with a 5’

cord (minimum) extending beyond the rear of the unit. The electrical

outlet must be flush with, or recessed into, the back wall.

DANGER

ELECTROCUTION HAZARD!

Electrical grounding required. This appliance is equipped with a

3-prong (grounding) polarized plug for protection against pos-

sible shock hazards.

• Never remove the round grounding prong from the plug.

• Never use a 2-prong grounding adapter.

• Never use an extension cord to connect power to the unit.

If a 2-prong wall receptacle is encountered, or a longer power

cord is required, contact a qualified electrician to install the

proper 3-prong receptacle in accordance with applicable electri-

cal codes.

DANGER

Failure to comply with the above electrical guidelines may result

in possible injury/death/fire or loss of property.

UNPACKING AND MOVING THE UNIT

CAUTION

Do not cut cardboard sleeve covering the unit. Cutting may result

in damage to the exterior of the unit.

1. Uncrate the unit outside on a flat level surface. Remove the card-

board sleeve by removing the banding holding the sleeve to the

shipping base. Carefully lift the cardboard sleeve up over the top

of the cabinet.

2. Carefully lift unit off base and onto a hand truck or dolly (this

should be done with a minimum of two people, larger cabinets

may require additional helpers). Make sure unit is balanced on

transporting device. Secure unit to transporting device using soft

flexible strapping. Protect cabinet surfaces with cloth material

where strapping contacts the unit.

3. Before moving unit, secure door to unit with tape to hold the door

closed.

WARNING

A minimum of two people should lift the cabinet off the base to

prevent possible personal injury.

4. Carefully move unit to installation site and place in front of open-

ing.

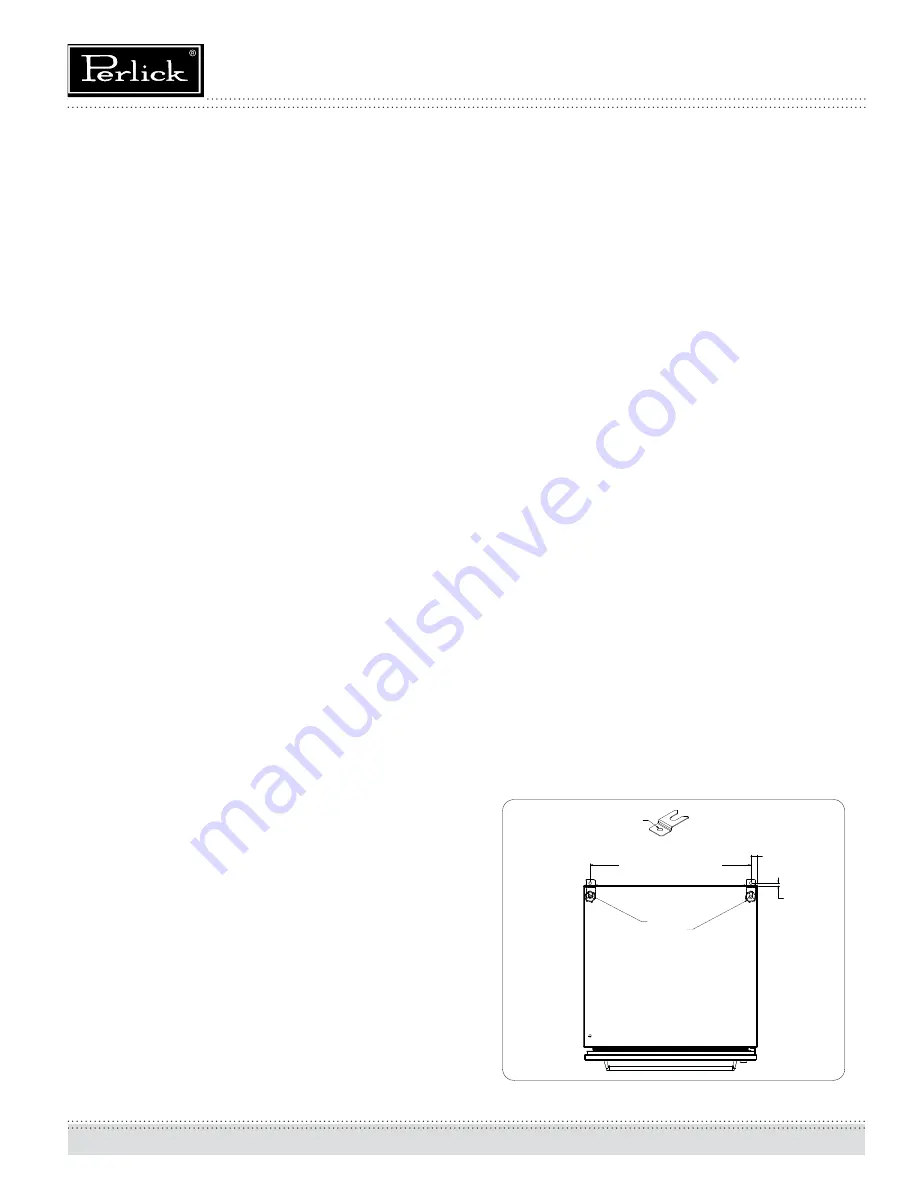

ANTI-TIP BRACKETS

WARNING

Unit may tip forward if loaded racks/shelves are all pulled out at

the same time. To prevent tipping and provide a stable installa-

tion, the unit must be secured in place with the anti-tip brackets

provided with the unit.

A set of metal anti-tip brackets and #10 x 3/4” screws are supplied with

the unit. The anti-tip brackets, when properly installed, should secure

the rear legs and prevent the unit from tipping forward.

Some installation sites may require modification to provide a secure

surface for attaching the brackets. Refer to Figure 2 for mounting

bracket locations.

IMPORTANT: If installing on a concrete floor, concrete fasteners are

required and are not included in the Anti-Tip kit.

5HDU/HJV

)25&$%,1(76

)25&$%,1(76

'LDPHWHU

$QWLWLSEUDFNHW

3DUW

Figure 2. Anti-Tip-Over Bracket Mounting