13

Perlick.is.committed.to.continuous.improvement..Therefore,.we.reserve.the.right.to.change.specifications.without.prior.notice.

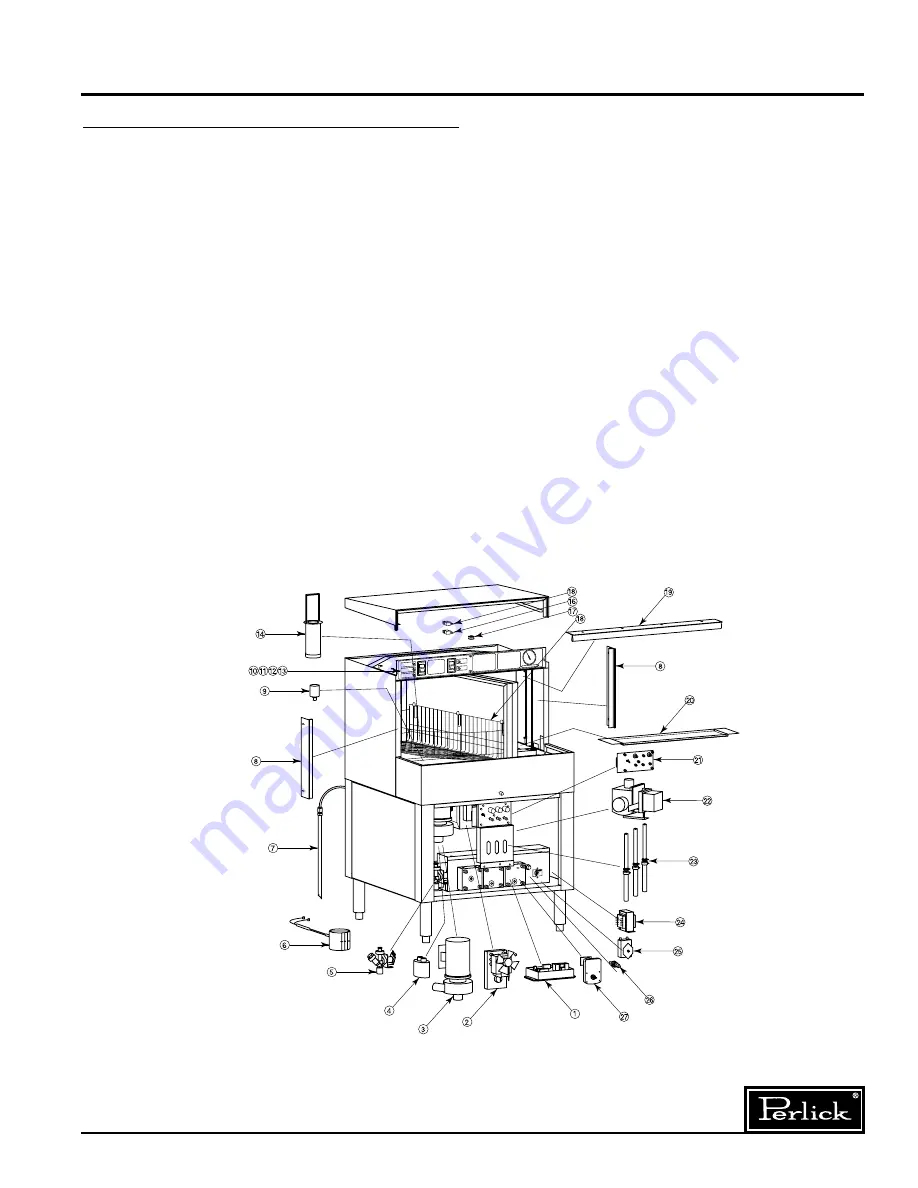

MAINTENANCE.AND.TROUBLESHOOTING

Replacement Parts

ITEM

NO.

dESCRIPTION

PART NO.

.. 1.

Glasswasher.Control.Kit.

55042

.. 2.

Spray.arm.drive.motor.

52536

.. 3.

Wash.pump.

50445

.. 4.

Pump.motor.capacitor.

52528

.. 5.

Water.inlet.valve.

52652-1

.. 6.

Band.heater.

52669-1

.. 7.

Rinse.aid.pickup.tube.assembly.

52626A-B

. .

Detergent.pickup.tube.assembly.

52626A-R

. .

Sanitizer.pickup.tube.assembly.

52626A-W

.. 8.

Divider.side.seal.

52696

.. 9.

Wash.water.level.switch.

R54978-1

. 10.

Start/Wash.switch.

55003-1

. 11.

Power/drain.(on/off/drain).switch.

55004-1

. 12.

Red.light.

54809

. 13.

Amber.light.

54810

. 14.

Wash.tank.filter.

52492

. 15.

Safety.switch.-..250".quick.connect.

54995-1

. 16.

Safety.switch.-..187".quick.connect.

54996-1

. 17.

Roller.bearing.for.divider.lock.

C12698-1

ITEM

NO.

dESCRIPTION

PART NO.

. 18.

Glass.rack.

50470-2

. 19.

Top.divider.seal.

52692

. 20.

Top.wash.tank.screen.

50588

. .

(For.Serial.Nos..to.443593.only)

. 20A..

Top.wash.tank.screen.

R50614

. 21.

Chemical.system.control.board.

50453

. 22.

Drain.valve.

50451

. 23.

Chemical.system.sight.tube.kit.

52714A

. 24.

Transformer.

52566A

. 25.

Temperature.control.

54153A

. 26.

Fuse.holder..

54938-1

. .

12.amp.fuse.

54939-1

. 27.

Chemical.pump.gear.motor.

52537

PARTS NOT ShOwN

. .

Chemical.bulkhead.fittings.

R54976

. .

Amber.chemical.sight.tube.light.

54790

. .

Flat.strainer.

54965-1

. .

Clean-out.plugs.for.spray.arms.

R54900-1

. .

1

⁄

4

".ID..chemical.pump.squeeze.tube.

52679-1

. .

3

⁄

16

".ID.chemical.pump.squeeze.tube.

52681-1

. .

1

⁄

8

".ID.chemical.pump.squeeze.tube.

52680-1

. .

Seal.kit.

R54965