Check Engine and Clutch Oil

IMPORTANT: Low oil level can cause serious engine or clutch

damage. Check oil level regularly. Check before operating. Keep oil

level between “full” and “add” marks. Do not operate engine if oil

level in engine or clutch are below or above the full and add marks.

Check

engine

Service Manual

35

oil Level

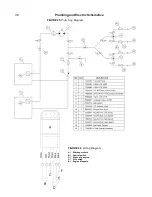

(Refer to

FIGURE 19

)

Park safely on level ground.

Let engine cool.

Clean around engine dipstick.

Remove engine

OIL FILLER CAP/DIPSTICK

and wipe it clean.

Insert engine

OIL FILLER CAP/DIPSTICK

into the oil filler neck

as shown but do not screw it in, then remove it to check the oil

level.

If oil is near or below the lower limit mark on the dipstick, fill with

the recommended oil (refer to Table Engine and clutch oil type

on the next page) to the upper limit mark (bottom edge of the oil

fill hole).

DO NOT

overfill. If oil is above the full mark, drain

excess oil.

Replace Oil filler cap/dipstick.

Changing engine oil (Refer to FIGURE 20)

Drain the used oil when engine is warm. Warm oil drains quickly

and completely.

Clean around Dipstick and oil drain plug.

On a level surface, place the machine in a maximum left turn

and Lock both Brakes.

Place an oil drain pan under the drainage hole in the motor plate

to catch the used oil.

Remove oil filler cap/dipstick, drain plug and washer.

Allow oil to drain completely into pan.

Reinstall the drain plug and new washer, and tighten the drain

plug securely.

Add recommended oil (refer to Table Engine and clutch oil type

on the next page) and use dipstick to check level as described

in the “checking engine oil” section above.

Read Safety Manual

WARNING 21

Handling and Disposal

of hazardous waste products before starting or operating

the Triumph.

Read Safety Manual

WARNING 14

, Parking before starting or

operating the Triumph.

Read Safety Manual

WARNING 5

, Safety Devices now.

FIGURE 19

, Checking engine oil

FIGURE 20

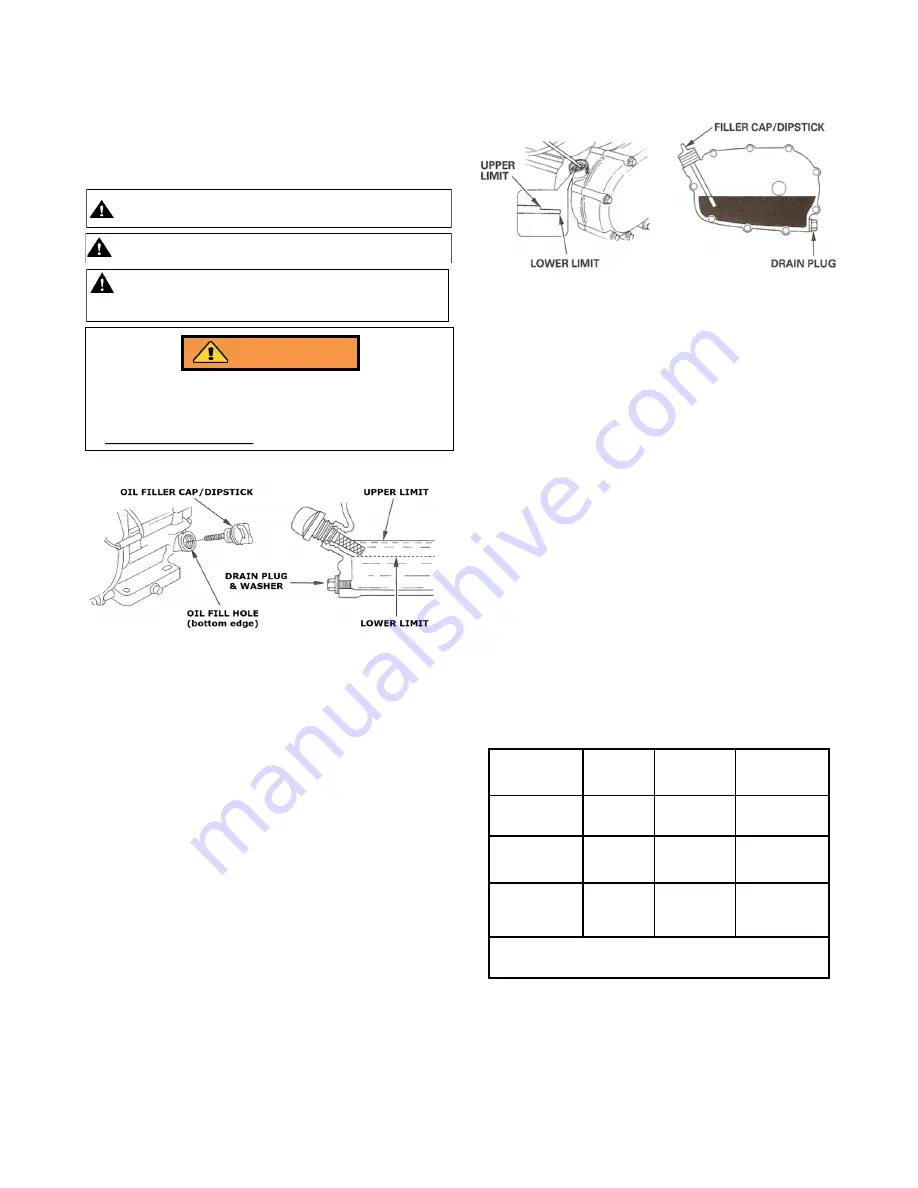

Check clutch oil Level

Checking clutch oil (Refer to FIGURE 20)

Remove clutch

OIL FILLER CAP/DIPSTICK

and wipe it clean.

Insert clutch

OIL FILLER CAP/DIPSTICK

into the oil filler neck

as shown but do not screw it in, then remove it to check the oil

level.

If oil is near or below the lower limit mark on the dipstick, fill with

the recommended oil (refer to Table Engine and clutch oil type

on the next page) to the upper limit mark (bottom edge of the oil

fill hole). Do not overfill. If oil is above the full mark, drain excess

oil.

Replace Oil filler cap/dipstick.

Changing Clutch oil

Referring to

FIGURE 20

, Checking Clutch oil:

Drain the used oil when engine is warm. Warm oil drains quickly

and completely.

Clean around Dipstick and oil drain plug.

On a level surface, place the machine in a maximum left turn

and Lock both Brakes.

Place an oil drain pan under the drainage hole in the motor plate

to catch the used oil.

Remove oil filler cap/dipstick, drain plug and washer.

Allow oil to drain completely into pan.

Reinstall the drain plug and new washer, and tighten the drain

plug securely.

Add recommended oil (refer to Table Engine and clutch oil type

on the next page) and use dipstick to check level as described

in the “Checking engine oil” section above.

Temperature

Range

Oil Type

Oil

Volume-

Engine

Oil Volume-

Clutch

+50ºF (10° C)

and higher

SAE 30

0.63 quart

(0.6 liter)

0.53 US quart

(0.5 liter)

+50ºF (10° C)

and higher

SAE 10W

-

30

0.63 quart

(0.6 liter)

0.53 US quart

(0.5 liter)

+30ºF to -

22ºF

(0°C to -30°C)

SAE

5W-30

0.63 quart

(0.6 liter)

0.53 US quart

(0.5 liter)

Table. Engine and Clutch Oil Type, Volume, and

Temperature Range

This product can expose you to chemicals including Ethyl

Benzene, Naphthalene, N-Hexane, and Benzene which are

known to the State of California to cause cancer and birth

defects or other reproductive harm. For more information go

to www.P65Warnings.ca.gov

WARNING