Magnum C3C Spreader Sprayer

Operator Manual

Refer to the cover page for restrictions regarding

Page 12

reproduction or disclosure of this material.

Septenber/08

DESCRIPTION

1.

Technical Description

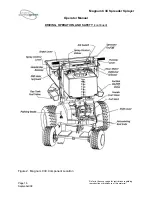

The major functional elements of the PermaGreen Magnum C3C are described below

(refer to Figure 2).

•

The PermaGreen Magnum C3C Spreader Sprayer is built on a heavy gauge

stainless steel frame. A polyethylene hood protects the undercarriage components

from the dust and chemicals from the Spreader Sprayer and protects the operator

from moving parts.

•

The Spreader Sprayer operating, steering, and drive components are mounted on

the front section of the two-section machine. The rear section is a sulky that the

operator stands on during operation. The front brakes aid in controlling the

machine. The handlebars independently operate the steering brakes.

•

The Spreader Sprayer uses a pull-start, 200cc Honda Model GX200-HR2 engine

that has an integral 1:2 gear reduction transmission with an oil-bath, centrifugal

clutch. The heavy duty, hand-operated, centrifugal clutch engages when the

engine speed is increased above idle.

•

Normal engine idle speed is 1400 + 200/-150 rpm. When the engine is operating

at full throttle, the normal engine operating speed is 3450 rpm.

•

The transmission provides high and low forward speeds, neutral, and reverse. At

an engine speed of 3450 rpm, high gear provides a forward speed of 5 mph (8

km/h). Low gear provides a forward speed of 3.5 mph (5.6 km/h).

•

The interface between the engine/gearbox and transaxle is through a horizontal

drive shaft and a belt and pulley arrangement.

•

The interface between the gearbox and the spreader is through a jackshaft and

belt/pulley arrangement to a 1:5 ratio gearbox that results in a speed reduction to

approximately 411 rpm at both high speed and low speed operation.

•

The spreader is designed and manufactured by PermaGreen Supreme. The

spread pattern and spread rate are adjustable. A remotely operated deflector limits

the spread pattern to the left side only for edging. When using the deflector, a

remotely operated sliding plate closes the third hole to proportionally reduce the

product flow and balance the spreader pattern.

•

The hopper has been designed and built specifically for the Magnum C3C

Spreader Sprayer. Its capacity is 150 pounds (68 kilograms) of granulated

material. The hopper includes a shower cap that covers the hopper during rain.