51

Troubleshooting

Troubleshooting R-net

3.16 DIME Error

This occurs when the control system detects an ID conflict between two modules in the system.

If a new module has been added:

• Disconnect the new module and cycle the voltage.

• If no error occurs, connect the new module to the system and cycle the voltage.

• If the error recurs, the new module must be the cause of the problem.

If no new modules have been added:

• Disconnect one module at a time and cycle the voltage.

If the error persists after the checks listed above have been performed, consult your service contact or

Permobil

.

3.17 Memory Error

This is a non-specific memory error that may be caused by any of the system modules.

• Check all cables and connections.

• Cycle the voltage.

If the error persists and the system includes third-party modules:

• Disconnect all modules that do not come from PGDT and cycle the voltage.

If this has dealt with the error:

• Connect one third-party module at a time and cycle the voltage each time.

• If the error recurs after one of the voltage cycles, the last module to be connected must be defective.

If the error persists after the checks listed above, the power module may be defective. Read more in

section 5.

3.18 PM Memory Error

This is a specific error in the power module.

• Check all cables and connections.

• Reprogram the control system with the help of R-net’s PC programmers.

This should be done with either the latest specific program file for the wheelchair or Permobil’s original

program file.

If the error persists after the checks listed above, the power unit may be defective. Read more in section

5.

m

nB

Programming should only be performed by persons with sound knowledge of control systems from PGDT. Incorrect programming

can mean that the wheelchair is not safe to use. Permobil cannot be held responsible for losses of any kind if the control system

factory settings are altered by programming.

Summary of Contents for C300

Page 1: ...SERVICE MANUAL Permobil K C300 Power wheelchair US ...

Page 2: ......

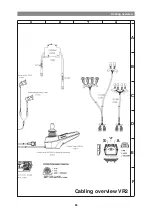

Page 62: ...62 Cabling overview A B C D E F 1 2 3 4 ...

Page 63: ...63 Cabling overview Cabling overview R net A B C D E F 5 6 7 8 ...

Page 64: ...64 Cabling overview A B C D E F 1 2 3 4 ...

Page 65: ...65 Cabling overview Cabling overview VR2 A B C D E F 5 6 7 8 ...

Page 67: ......

Page 68: ...Order no 205221 US 0 ...