29

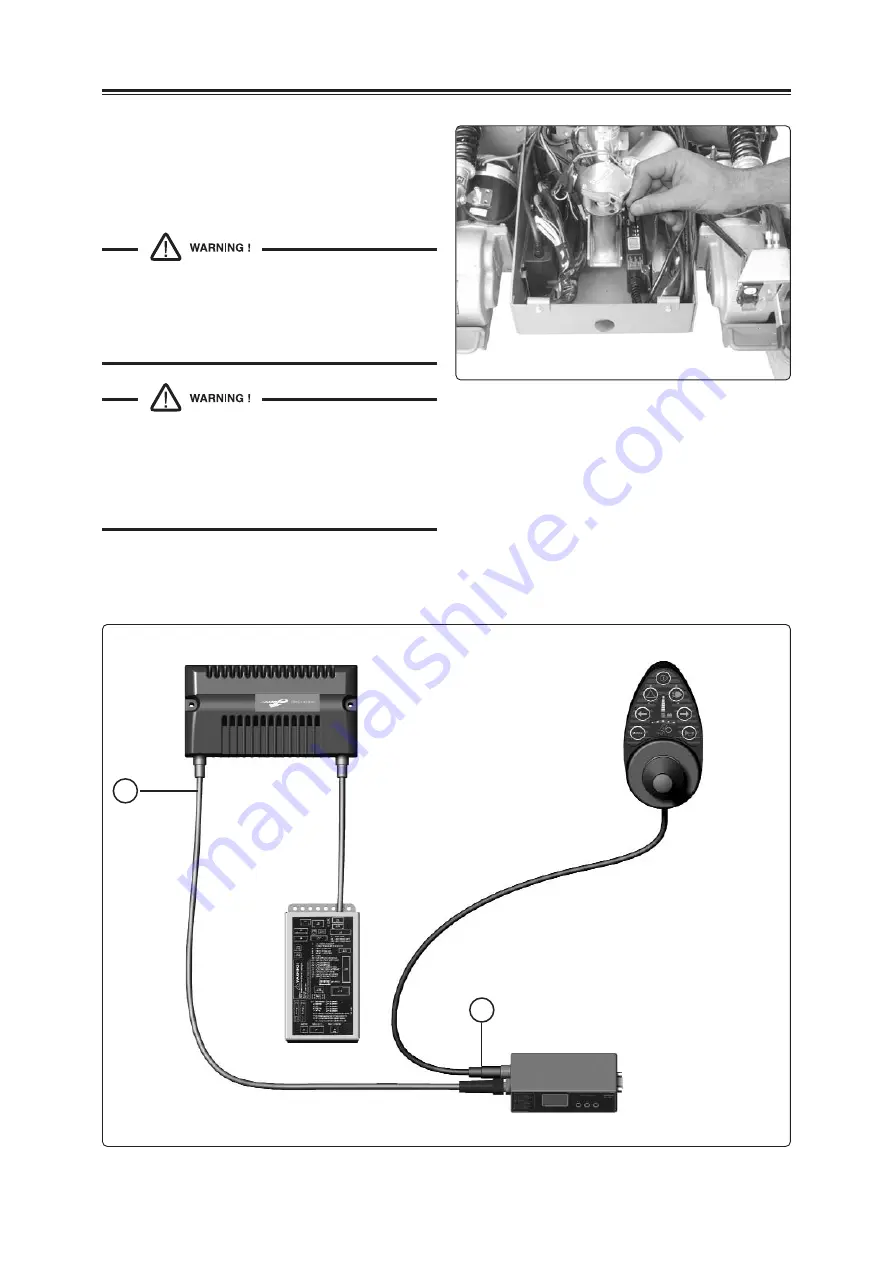

ESP module

5.

The ESP module is ready programmed from

the factory. If the module is to be

reprogrammed, see the technical manual of

the ESP module for full details.

Warning!

The ESP module and the Pilot+ output

connection must be correctly programmed when

the wheelchair is in use. Otherwise the wheelchair

may be very difficult to maneuver, with a high risk

of accidents.

Fig. 65. The connections to the ESP module.

Warning!

Test the way the wheelchair runs in a

large open space. If the ESP module is incorrectly

installed or incorrectly programmed, the chair may

move rapidly in the wrong direction. Check

carefully that it runs correctly in response to the

controls.

Fig. 64. Programming the ESP module.

1

2

Summary of Contents for Chairman 2k

Page 1: ...SERVICE MANUAL Chairman 2k 2s US ...

Page 2: ......

Page 32: ...32 Distribution chart A B C D E F 1 2 3 4 ...

Page 33: ...33 Distribution chart Distribution chart A B C D E F 5 6 7 8 ...

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ...Article no 201158 US 0 ...