Accessory Installation

Always turn off the air supply and disconnect the air supply hose before installing, removing or adjusting any

accessory on this tool or before performing any maintenance on this tool. Failure to do so could result in an

injury.

1.

Open the retainer.

2. Insert the drill rod into the hammer.

3. Close the retainer.

• Do not repair the tool at the work site. Always take the tool to a repair shop. Never drag the tool on the ground.

The air port and other openings will become clogged with dirt and debris.

• Compressed air is dangerous. Avoid pointing the hose at any of your co-workers or yourself and never use the

air to clear the worksite or work clothing.

• Do not operate the tool unless the drill steel is pushed against the worked material to avoid premature wear of

parts and reduce the vibration isolation properties of the tool.

The starting lever has 4 positions:

1/ The starting lever is perpendicular to the hammer axis – STOP

2/ The starting lever is 45 degrees forwards – SLOW DRILLING

3/ The starting lever is forwards parallel with the hammer axis – FULL DRILLING OUTPUT

4/ The starting lever is backwards – FLUSHING THE HOLE

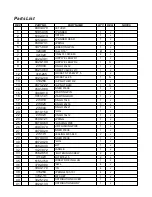

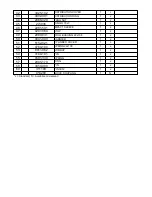

SPECIFICATIONS

Weight

kg

26,5

Length

mm

720

Height

mm

285

Working Pressure

bar

4 – 6

Air Consumption

m

3

/min

4

Impacts per Revolution

–

16

Impact rate

1/min

2100

Chuck Size

mm

hex. 22X108

Air Supply Hose

mm

25

Water Supply Hose

mm

13

Torque

Nm

16

DISASSEMBLING THE VK23 ROCK DRILL

GENERAL INSTRUCTIONS

• Clean the outer surface of the rock drill.

• Do not disassemble the rock drill any further than necessary to replace or repair damaged or worn parts.

• Whenever grasping the rock drill in a vice, always use leather or copper covered vice jaws to protect the

surface of the part and help to prevent distortion. Take extra care with threaded parts and housings.

• Do not remove any part that is a press fit in or on a subassembly unless the removal of the part is necessary

for repairs or replacement.

• Do not disassemble the rock drill unless a complete set of seals and o-rings is available for replacement.

All components are hold together by 2 side bolts (33). Screw out the nuts (34), remove side bolts (33) and

handle (32).

Remove the cylinder cover (51) step by step with the stirrup (52) and drill bushing (49), impact sleeve (46),

piston (2) with the tang nut (44), cylinder (1) with the pin (60), bottom distribution cover (42) with the stop (47),

distribution body (41), upper distribution cover (40), distribution ring (43), ratchet (39) with the screw driving lug

(35), pawls (36), pins (37) and springs (38).

Warning! The threads of the tang nut (44) and the carrier (50) are left-handed!

Summary of Contents for VK 23

Page 6: ......