PERMON s.r.o. VKP 95-1 – OPERATION MANUAL PAGE 3

Preface

This operation and maintenance manual provides the drawings, parts lists and

suggested procedures necessary for the operations, care and maintenance of the

VKP 95-1. It is extremely important that all the suggested safety precautions, as well

as user’s safety rules, be followed. PERMON is not responsible for damage to

equipment or personnel injury due to misuse of the equipment or disregard for safety

procedures.

Principles of Operation

The VKP series of downhole hammer drills are designed for efficient operation with

minimum air requirements in a wide range of air pressures. These hammers are

recommended for blasthole drilling in quarries and open pit mines as well as water

well and construction drilling applications. The downhole drilling method has proven

to be economically effective in a wide range of rock types ranging from

unconsolidated limestones to the hardest granite and quartz formations. Since the

hammer force is applied directly to the drill bit, power transmission losses as are

common in conventional top hole hammers are prevented.

These hammers can be used on any rig having an adequate rotational mechanism

and an appropriate compressed air supply.

Specifications

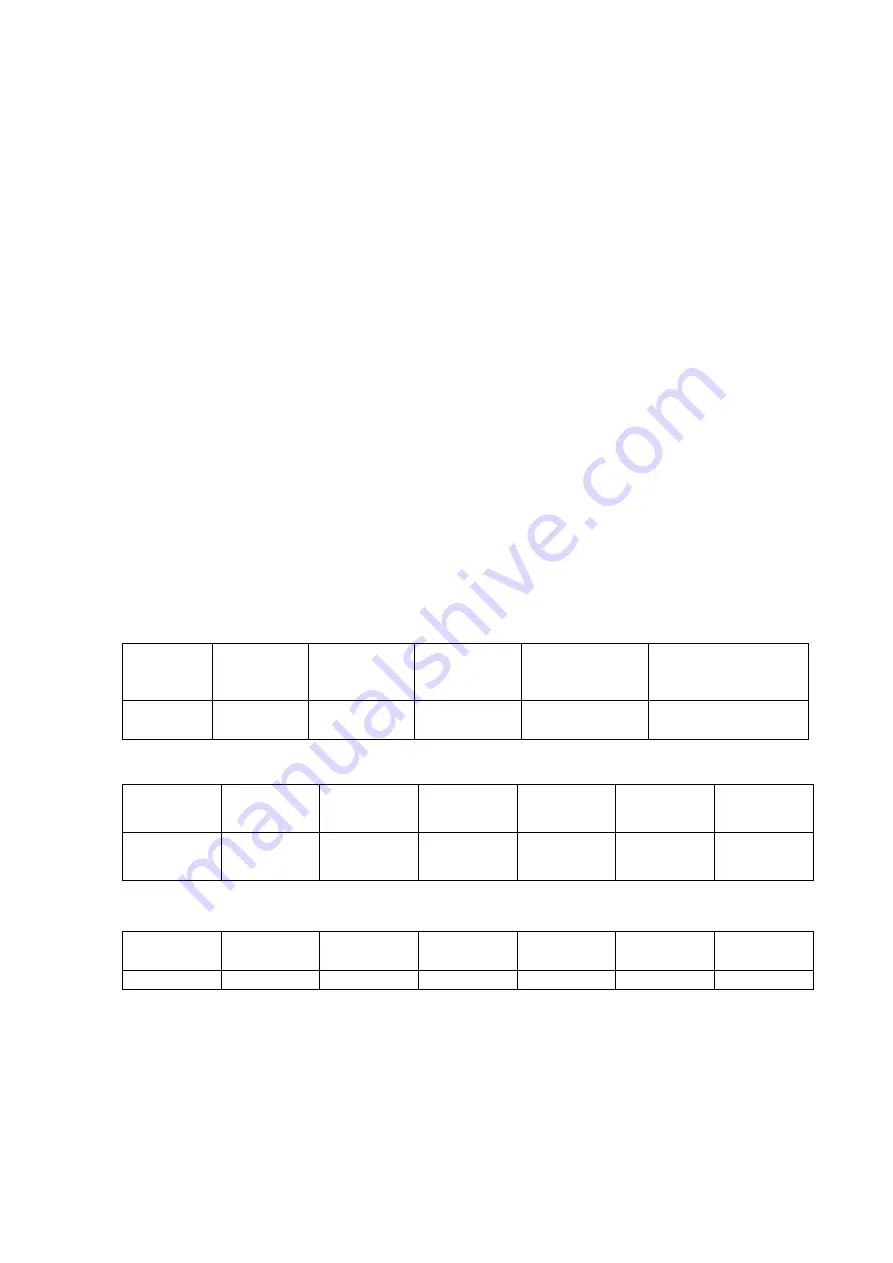

Hammer

Type

Connection

Thread

Shipping

Weight

Outside

Diameter

Length without

Bit

Bit Size Range

kg

lbs.

mm

in.

mm

in.

mm

in.

VKP 95-1

API 2 3/8”

Reg. Box

22,5

49.5

81,0

3.19

790

31.10 92-105 3 5/8-4 1/8

Air Consumption

6 Bar

9 Bar

12 Bar

15 Bar

18 Bar

21 Bar

24 Bar

90 PSI

130 PSI

175 PSI

220 PSI

260 PSI

305 PSI

350 PSI

3,3 m

3

/min

5,2 m

3

/min

7,1 m

3

/min

9,2 m

3

/min

11,6 m

3

/min

13,7 m

3

/min

16,2 m

3

/min

117 SCFM

184 SCFM

251 SCFM

325 SCFM

410 SCFM

484 SCFM

572 SCFM

Impact Rate

6 Bar

9 Bar

12 Bar

15 Bar

18 Bar

21 Bar

24 Bar

90 PSI

130 PSI

175 PSI

220 PSI

260 PSI

305 PSI

350 PSI

1490/min

1830/min

2100/min

2320/min

2530/min

2620/min

2710/min