© Pertronic Industries Ltd

5

FAAST LT Loop-Based Installation & Maintenance Guide Iss 1.0, 201701

X 10

X 1

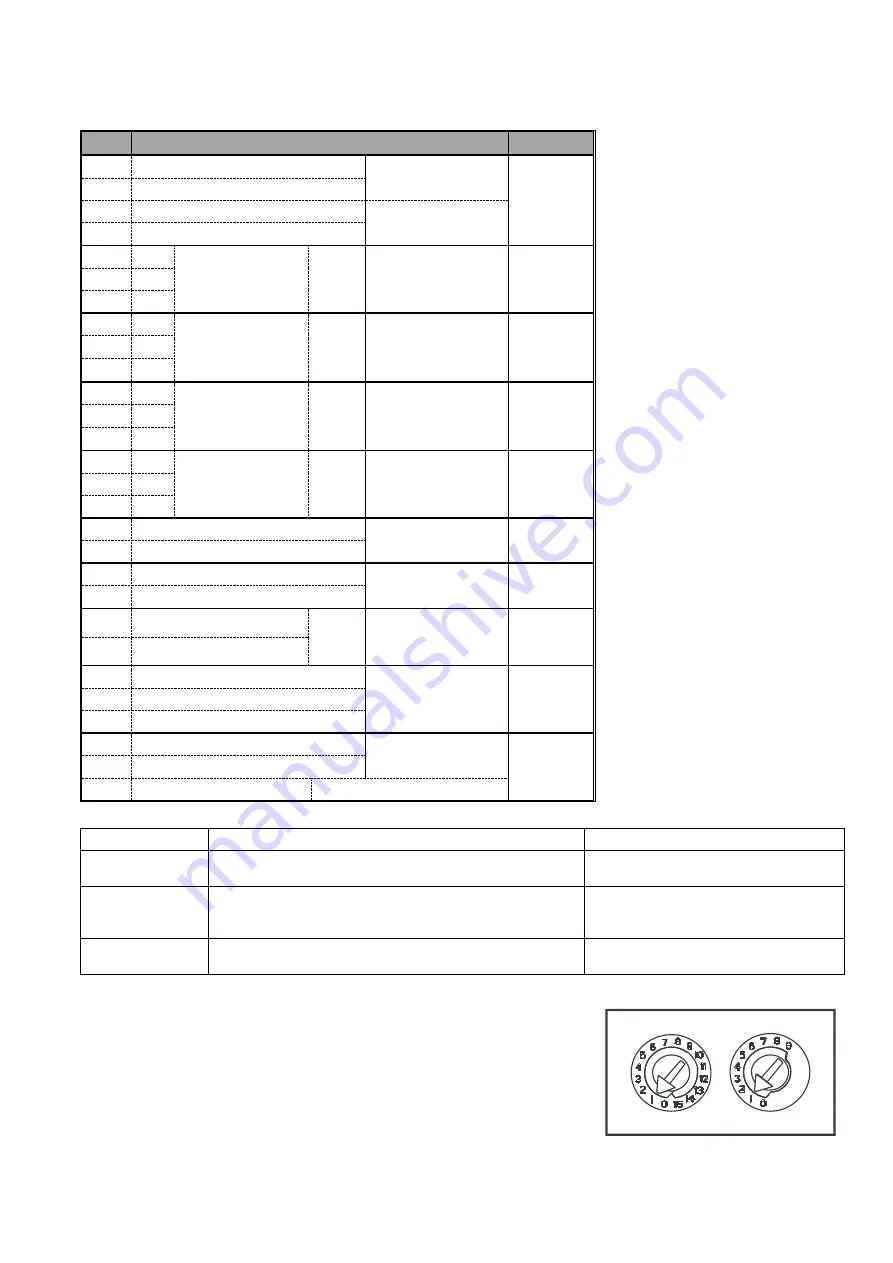

FL20nnEI Loop-Based Terminal Connections

Table 2: Wiring Terminal Designations

(Note - Terminals marked CH2 are only available on 2 channel models)

No

Function

Connector

1

Ext Power In +

Primary PSU

T1

2

Ext Power In -

3

Aux Power In +

Not Used in Default

4

Aux Power In -

5

NC

Alarm Relay

CH1

T2

6

C

7

NO

8

NC

Alarm Relay

CH2

T3

9

C

10

NO

11

NC

Fault Relay

CH1

T4

12

C

13

NO

14

NC

Fault Relay (AUX)

CH2

T5

15

C

16

NO

17

Sounder Output 1 -

47KΩ EOL Resistor

T6

18

Sounder Output 1 +

19

Sounder Output 2 -

47KΩ EOL Resistor

T7

20

Sounder Output 2 +

21

Configurable Input +

(Reset)

Default is Active

= Short-Circuit

(unsupervised)

T8

22

Configurable Input -

23

Not Used

To Use Isolator

T9

24

Loop Out -

25

Loop Switched Out +

26

Loop In -

T10

27

Loop In +

28

Loop Not Switched Out + Internally Connected to 27

Table 3: Relays

RELAY

ACTION

NOTES

ALARM 1 or 2

Controlled by the panel when it determines

Alarm condition

has been met.

Set ON and OFF by panel; not Latched

FAULT 1 or 2

When FAULT CONDITION on Ch1 or Ch2 or a common

FAULT occurs. Fault is also

signalled when in Service mode

and when

the device is unpowered

Fault state is not Latched (default)

SOUNDER 1 or 2

Set ON when a channel is in ALARM. Sounder 1

corresponds to Ch1 and

Sounder 2 corresponds to Ch2

Set ON in ALARM (default)

Setting the Sensor Addresses:

Each aspiration channel uses loop communications to report its

status

information to the CIE (Fire Panel).

As a factory default,

the unit will report Smoke Alarm and sensor

information at an

associated Detector address and general Alerts and

Faults on a

different Module address.

The default addresses are:

Channel 1 = 01

Channel 2 = 02

Figure 11: Address Switches

Setting the Detector Addresses:

Sensor:

the Sensor address is set

on rotary decade switches on the

rear of the Laser (7251) detector.

The sensors are located under

the

Sensor Cover inside the unit (see

Figure 10).

The Smoke Detector

section of

Service

(refer to Page

9) shows how to remove the

sensors

As supplied, the default address

for Channel 1 is Address 1; in 2

channel units, (or when two

detectors are fitted) the second

device is set to Address 2. Hence,

Address 99 is not valid for

Channel 1 on a two sensor

detector.

Module:

The Module address is set using

rotary decade address switches

located behind the

door - rotate

the

wheels to the desired address.

The selected

address refers to

Channel 1; on 2 channel

units the

device assigns the next (+1)

module

address to Channel 2

automatically.

Note:

the Module address only

responds to

a panel poll when in

Normal

mode.

Configure the Module as an

Output device: RLYM or as AUXM

if the ability to isolate it as an AUX

device is required.

In Alarm mode: By Sensor, the

module provides a detector Defect

to the panel, eg for an Aspirator

fault.

When the door is open the Module

reports MISSING