12

VB 230/400-25

12. Commissioning

:The device is to be put into opteration in 3 steps:

1. Mounting

2. Connection and

3. Parameter setting

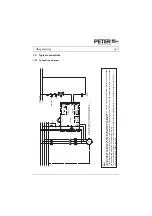

12.1 Mounting instructions

Caution: Danger to life through electric shock!

The following conditions are to be complied with in order to ensure a safe

and reliable operation of the VersiBrake:

1. The device series VersiBrake is to be used under overvoltage conditions of the

category III.

2. Make sure that pollution degree 2 or better, in accordance with IEC664, is

complied with.

3. The device is to be installed into a housing (min. degree of protection: IP54).

4. The device must be operated without being exposed to contamination by

water, oil, carbon deposits, dust, etc.

5. Insert in North America, UL and CSA-listed.

5.1 „Suitable For Use On A Circuit Capable Of Delivering Not More Then 5kA rms

Symmetrical Amperes, 480 Volts Maximum.“

5.2 „Use Copper Conductors 60/75°C or 75°C only.

Warning:

Make sure that a minimum distance to adjoining devices is kept. Above and

underneath the housing a minimum distance of 50mm is to be kept.