31

(d) Check that the large end bolts are tight (see Technical Data)

(e) Check for undue wear in the small end bush by rocking the piston

whilst holding the connecting rod firmly

43. To remove connecting rod

(a) Remove cylinder head and cylinder.

(b) Drain the oil from the sump.

(c) Remove the sump

(d) Unscrew the large end bolts and withdraw the connecting rod and

piston assembly, being careful to note in which position the bearing

halves are fitted.

44. Connecting rod maintenance

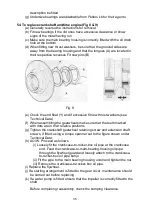

(a) When fitting a small end bush take care that the oil hole coincides with

(hat in the connecting rod and that the bush enters the connecting rod

squarely In the absence of a press, a block of wood and mallet may be

used for driving it home

(b)

New small end bushes are supplied with a reaming allowance, and

after fitting must be reamed to the size shown under Technical Data.

(c) Large end bearings are of the precision thin wall steel back type and

consist of two half shells lined with bearing metal. They should be

replaced in their original positions

(d) New bearings are machined to give the required fit when in position

and should not be scraped or bedded in, neither should shims of any

description be fitted If the faces of the connecting rod or its cap are

filed the rod becomes useless regarding replacement bearing shells

When fitting make sure that the connecting rod bore, the outside of the

shells and their split faces are clear

(e) Connecting rods and caps are stamped with an assembly serial

number and care must be taken that numbers are correctly assembled

and on the same side

(f) Undersize bearings are obtainable from Petters Ltd or their agents.

45. To replace connecting rod

(a) Generally reverse the instructions for removal, making sure that the

connecting rod cap is away from the dipstick side of the engine.

(b) Tighten the large end bolts using a torque spanner set to the figure

shown under Technical Data

(c) Do not over-tighten the large end bolts or the bearing may distort. If a

torque spanner is not available, the bolts may be tightened using a

moderate force on a spanner gripped approximately 8in (200mm) from

the bolt

(d) When replacing the cylinder and cylinder head, check the bumping

clearance and valve rocker clearance.

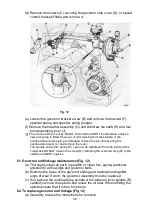

46. 4:1hand starting (flywheel end)

(a) To remove

(i) Remove the starting gearwheel guard.

(ii) The gearwheels can now be greased using a high melting point