44

body using a torque spanner set to the figure shown under Technical

Data.

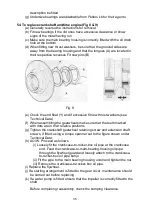

(d) When assembling the rack (P) and pinion (S) make sure that the

marked tooth of the pinion is opposite the mark on the rack and that

the rack is assembled in the pump body so that the 'STOP' mark and

arrow will be towards the gear end of the engine when the pump is

fitted

(e) Make sure that the element (U) can be moved up and down slightly

when the locating screw (T) is tightened.

(f) Replace the plunger (M) with the marked locating arm engaged with the

marked slot in the pinion (S). ie., the marked locating arm is towards

the locating screw (T).

(g) With the element, plunger and pinion correctly assembled, the scroll at

the top of the plunger will be adjacent to the fuel port in the side of the

element when the rack is in the centre of its travel.

(h) Replace the tappet (J) making sure that the correct number and

thickness of shims is used.

(i) Press down the tappet and roller assembly and fit the dowel (H) to

engage with the slot in the tappet. Rotate the dowel to line up its slot

with the ends of the circlip (G) and then turn the circlip in its groove

until the ends of the circlip are away from the dowel.

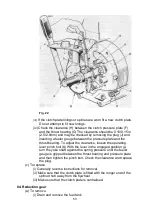

(j) Make sure that the fuel pump cam is away from the fuel pump housing

and turn the engine until the exhaust or inlet valve is open.

(k) Make sure that the fuel pump rack ball engages with the fuel pump

operating lever fork and that the correct number and thickness of

shims is fitted between the pump and the crankcase.

(l) IMPORTANT New fuel injection pumps require special fitting

instructions and these are given in the following paragraph.

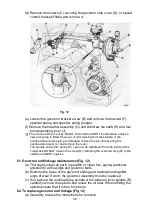

76. To fit new fuel injection pump (Fig. 15 & 16)

(a) Fixed speed engines

(i) Make sure that the fuel pump cam is at the bottom of its stroke.

Turn the engine until the exhaust or inlet valve is open

(ii) Turn the stop/run lever (B) until the fuel pump operating lever fork

end is at the centre of the fuel pump housing.

(iii) Fit the fuel pump. Make sure that the fuel pump rack ball (S) has

engaged with the operating lever fork.

(iv) Time the fuel pump

(b) AB1W. Variable speed engines

(i) to (iii) as for fixed speed engines.

(iv)

Loosen the overload stop cam screw (M).

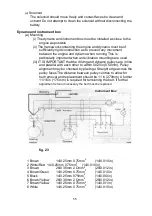

(v) Turn the stop/run lever fully towards the 'STOP' position, and

measure the distance (Y) between the end of the fuel pump rack

and the gear cover face using a depth gauge

(vi) Add 0 SOOln (12 70mm) (Z) to the depth gauge reading and

reset the fuel pump rack in this position by turning the stop/run

lever towards the 'RUN' position.

(vii) Hold the rack in this position and set the overload stop cam (N)

to just touch the overload stop on the fuel pump operating lever.