30

EN

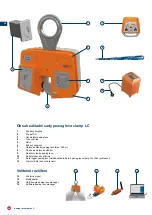

pewag levo clamp LC

Fig. 9: pewag levo Multi-adapter charging station

6.3 pewag levo manager

The optional pewag levo manager software is a comprehensive

configuration and analysis tool for the pewag levo clamp LC

as well as for other pewag levo products. Among others, the

programme offers the following options:

• Connection of several pewag levo clamps LC and radio control

units at the same time.

• Formation of pewag levo clamp LC groups.

• Alarm feature (temperature restriction).

• Monitoring of live data (opening, closing, actual temperature).

• Configuration of various parameters.

• Export of historical data of the pewag levo clamp LC.

For a detailed list of the individual functions of the pewag levo

manager, please contact your supplier and/or read the respective

manual. The software must be installed on a Windows PC or laptop.

6.4 pewag levo manager USB Dongle

The levo manager USB Dongle is

required for the communication

between the pewag levo clamp

LC/radio control unit and the

pewag levo manager software.

Wireless communication is set up

by connecting the device to the

USB port of a Windows computer.

The communication does not

require internet, it also works

on a radio frequency basis. The

maximum transmitting distance is

100 m (unobstructed).

6.5 pewag levo clamp LC data logger

A data logger is a processor-controlled storage unit that records

certain data via an interface and stores it in a storage medium.

The following data will be saved:

• Temperature during the operation.

• Opening/Closing cycles.

• Power on/Power off of the pewag levo clamp LC.

• Errors on the pewag levo device.

Further information can be found in the pewag levo manager

handbook.

7. Attaching and lifting the load

7.1 Attachment to the crane hook

Using the attachment mechanism, the pewag levo clamp LC

may be attached directly to a crane hook (single hook acc. to

DIN 15401, size 2.5). For larger crane hooks, a transition link

or similar must be used. Always ensure that all parts have the

required load capacity (crane hook, transition link etc.) The

connection must be made in such a way that unintentional

release is not possible (e.g. using a safety catch). The hook

attached to the attachment mechanism must be able to

move freely and must not touch the ground or the side of the

attachment mechanism. The attachment mechanism must be

positioned centrally and at the bearing area. Tip-loading is not

permissible.

7.2 Lifting and lowering the load

Prior to lifting:

• Ensure that the maximum load capacity is not exceeded.

• Ensure that the load is min. 10 % of the maximum load capacity.

• The pewag levo clamp LC must be loaded only vertically. It is

not allowed to use the pewag levo clamp LC as a horizontal

clamp (see chapter 4.1).

• It is not allowed to lift a package of sheets. Lift only one sheet

per lifting.

• It is not allowed to pull a sheet out of a package.

• When using only one pewag levo clamp LC, ensure that the

sheet is lifted symmetrical

• Attach the pewag levo clamp LC to the lifting mechanism.

• Ensure that all attachments have been tested and are of the

correct tonnage. Make sure that may be needed coupling

links and shackles are of sufficient dimensions to allow the

pewag levo clamp LC to move freely in the hook.

• Check whether the pewag levo clamp LC shows any visible

damage. Please ensure that the spring is in normal state.

If the spring breaks during load, please lower the load very

carefully and ensure the load against tilting.

• Press the open/close button to check whether the pewag

levo clamp LC opens and closes smoothly.

• Check whether the teeth of the cam are free from dirt and if

necessary clean with a wire brush.

• Remove any grease, dirt and mill scale from the plate at the

site of the pewag levo clamp LC.

• Press the open/close button to open the pewag levo clamp LC.

• Place the jaws as far as they will go over the plate, making

sure that the clamp is positioned so as the balance the load

when its being lifted.

• Close the pewag levo clamp LC by pushing the open/close

button.

During the lifting operation:

• Lift gently to allow lifting force to be applied; check whether

the pewag levo clamp LC is slipping.

• If the load is slipping, check the points addressed before

(Prior to lifting) again.

• If the load continues to slip, see chapter 9.2 – Maintenance.

• Start the lifting operation slowly and avoid abrupt lifting.

• Lift the load in such a way that it is prevented from swinging.

• Avoid sudden stops and shock-loading.

Fig. 10: levo manager USB Dongle