2

4.1

If the burner is to be mounted in an existing boiler or furnace, ensure that all fireside surfaces are clean

and in good condition. All doors, clean outs, cracks or other openings allowing excess air into the

combustion chamber should be tightly sealed, whether the burner is to be fired under positive or negative

Combustion Chamber conditions.

4.2

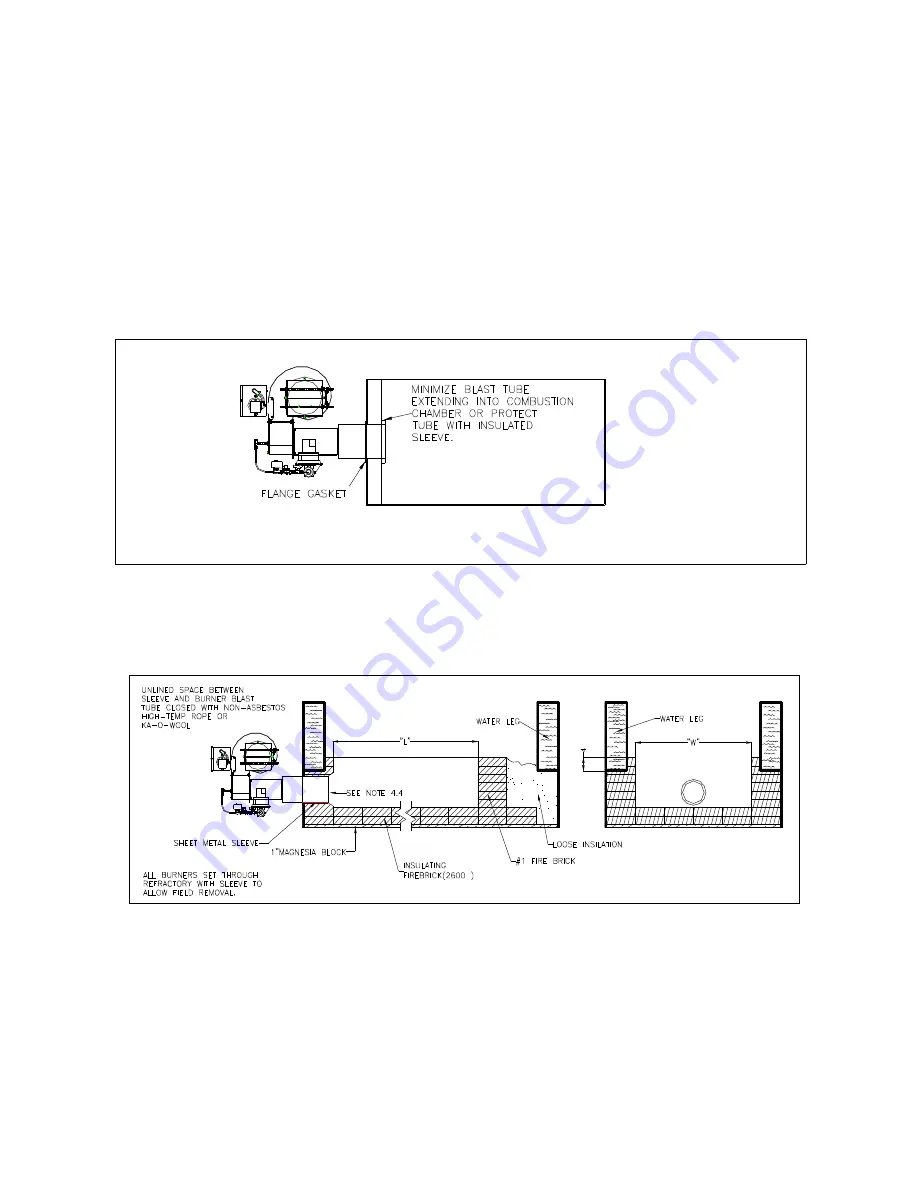

The burner can be mounted through a heat exchanger end wall or in the base of the boiler – see Figures

1 and 2. The opening for the burner blast tube should not be less than 6 ¼, 8 ¼, or 10 ¼ inches in

diameter (depending on the burner model) to allow easy removal of the burner. The gap between the

boiler opening and the blast tube should be sealed with non-asbestos, high temperature rope or Ka-O-

Wool. Where a new or replacement combustion chamber lining is to be used the chamber is to be built

using 2,300 degree F insulating firebrick or ceramic fiber blanket.

Figure 1. Mounting in Heat Exchanger

Figure 2. Mounting in Boiler Base