6

7.8

Connect a microampmeter or voltmeter to the Primary Safety Control as directed in the PSC

manufacturer’s instruction bulletin to determine flame detection system values. The meter is normally

connected in series with the (SENSE) terminal on the S8680 series control.

7.9

With the main and leak test cocks and pilot cock in

OFF

position, turn on the gas cock at meter. Check to

make certain that the pressure upstream of main and pilot cocks does not exceed 14” W.C. (1/2 PSIG) –

unless special valve train components suitably rated have been furnished (Refer to Burner Specification

Sheet). If pressure is acceptable, proceed to next step.

7.10

Pilot Ignition

Next check the operation of the gas pilot system. This is a very important part of the start up

procedure.

A.

Before attempting burner start up make certain that you are familiar with the operation of the

Primary Safety Control and other components being used on this specific application. Refer to

Fig. 5 and 5A for pilot spark gap dimensions.

B.

To prepare the pilot for proper operation, it is essential that appropriate adjustments be made on

the burner air inlet damper and to the pilot gas pressure. Initial air damper opening should be

approximately 1/8 inch open for low high low or modulating type models. On fixed rate burners

the air damper may have been factory set to a predetermined opening. The pilot pressure

needed will be affected by the damper position. Typical pilot pressure is 0.5” W.C. higher than

the static air pressure measured on the pilot during pre-purge for natural and propane gas.

C.

In many instances, pilot problems relate to gas pressures that are too high or too low,

causing the pilot gas mixture to be just outside of the ignition range. The optimum pilot

pressure should be determined by adjusting the pilot regulator and finding the minimum

and maximum pressure that the pilot lights. Then, set the pilot regulator where the

pressure is in the middle of these two pressures.

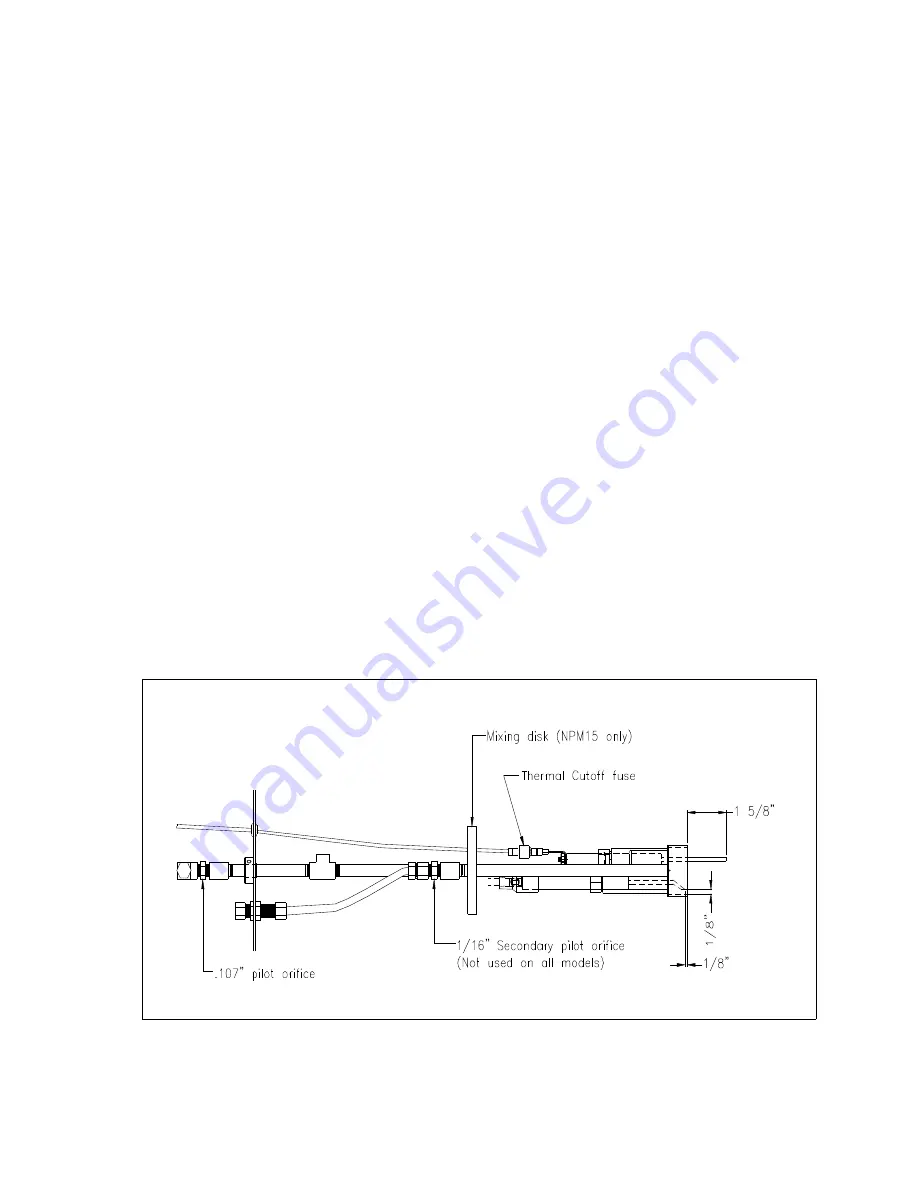

Figure 5. Pilot Assembly – Flame Rod Type – Natural Gas/LP Gas - NPM15 – 24 Volt