English

Wire rope winch GAMMA

4.1.244

Design changes under reserve

Page 7

Technical Data

Type

0270 004

0270 001

0270 006

0270 999

FEM Group acc. to DIN 15020/1

1 Em

1 Em

1 Em

capacity

load speed

(fast speed)

1st rope layer

[daN]

200

500

(90)

800

(90)

load speed

(fast speed)

2nd rope layer

[daN]

175

450

(75)

690

(75)

load speed

(fast speed)

3rd rope layer

[daN]

150

380

(65)

600

(65)

load speed

(fast speed)

4th rope layer

[daN]

140

350

(55)

520

(58)

load speed

(fast speed)

5th rope layer

[daN]

125

290

(50)

465

(52)

load speed

(fast speed)

6th rope layer

[daN]

115

260

(47)

420

(47)

load speed

(fast speed)

7th rope layer

[daN]

110

240

(43)

385

(43)

load speed

(fast speed)

8th rope layer

[daN]

-

220

(40)

355

(40)

rec. wire rope DIN 3060 FE-znk 1770 sZ-spa

ø [mm]

4

6

7

calculated braking force

[kN]

10,1

22,6

31,0

rope reception

1st rope layer

[m]

3,6

3,2

5,3

2nd rope layer

[m]

8,0

8,0

12,5

3rd rope layer

[m]

13,0

13,0

21,0

4th rope layer

[m]

19,0

19,0

30,0

5th rope layer

[m]

26,0

26,0

40,0

6th rope layer

[m]

33,0

34,0

52,0

7th rope layer

[m]

40,0

42,0

64,0

8th rope layer

[m]

-

50,0

78,0

ratio

-

6,57 : 1

7,57 : 1

required crank force

[daN]

18

12

18

average lift per full turn of crank

load speed

[mm]

245

50

53

fast speed

[mm]

-

335

395

securing of load

safety spring locking device

weight

[kg]

ca. 6

ca. 14

ca. 20

suitable for ambient temperature

-20°C +40°C

Functional Description:

The Aluminium hand winch is a drum winch with roller chain drive.

The load is automatically held by a spring loaded brake built into the drum.

By changing the crank sockets, the winch can be used for winding the unloaded rope on or off, respectively for

small loads in the fast speed.

Mounting Instructions

Mounting:

ATTENTION:

•

the mounting structure must be designed to

sustain the max. forces imposed by the winch

•

pay careful attention that the mounting sur-

face is flat and true,

•

only fix the winch by means of good quality screws

•

tighten the screws evenly

•

secure the screws

•

ensure that the crank is free running (

crank clearance

)

Mechanical Fixing:

Type

0270 004

0270 001

0270 006

0270 999

screws (material grade min 8.8)

M 8

M 10

M 12

number of screws

4

4

4

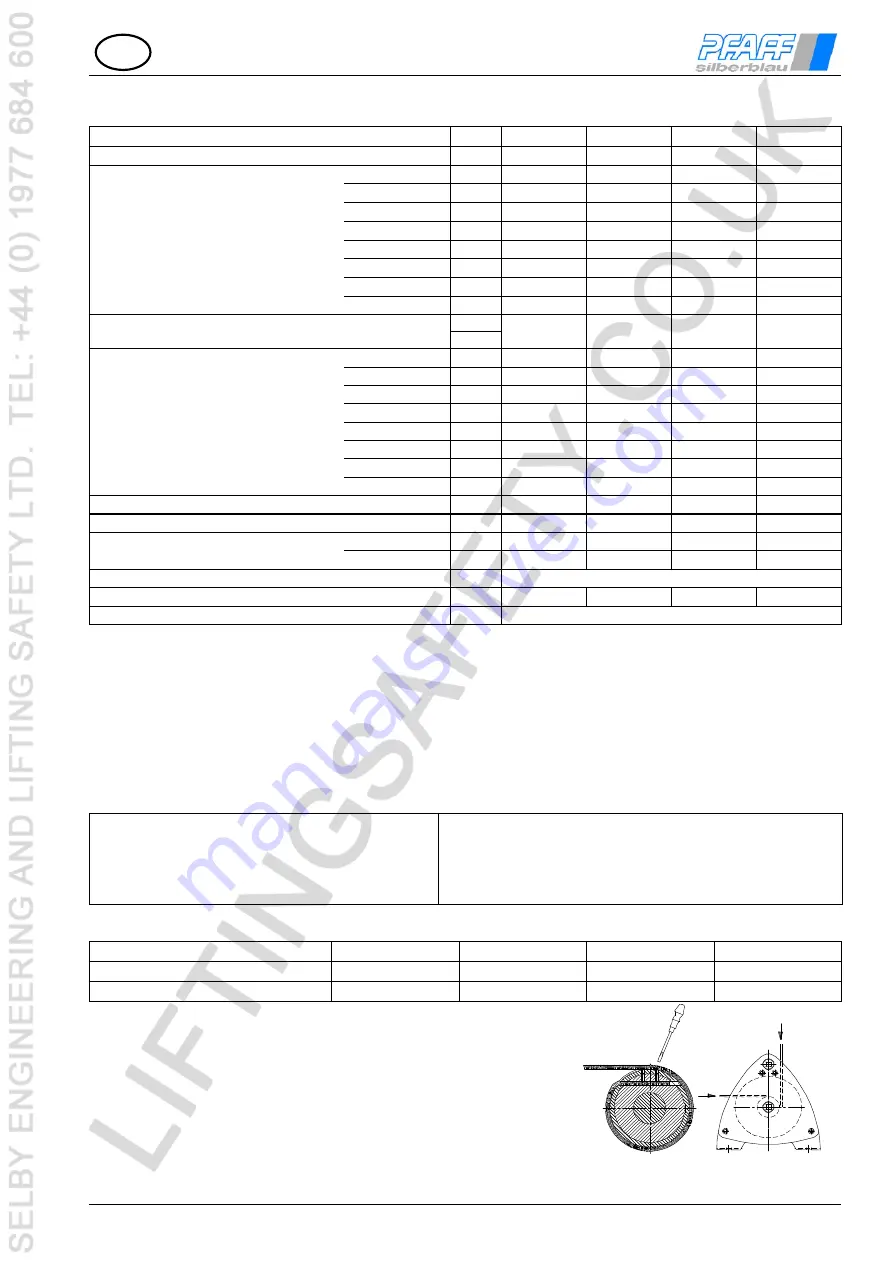

Wire rope fixing

ATTENTION:

With wrong rope coiling the brake is not effective.

Rope coiling has to be effected acc. to the drawing (direction by choice)

•

Insert the rope in consideration of rope winding direction.

•

Tighten clamping screw(s).

For rope selection pay attention to the technical data for the rope

Calculate the rope length in such a way that at least 3 full turns of

rope remain on the drum in lowest load position.

rope

direction