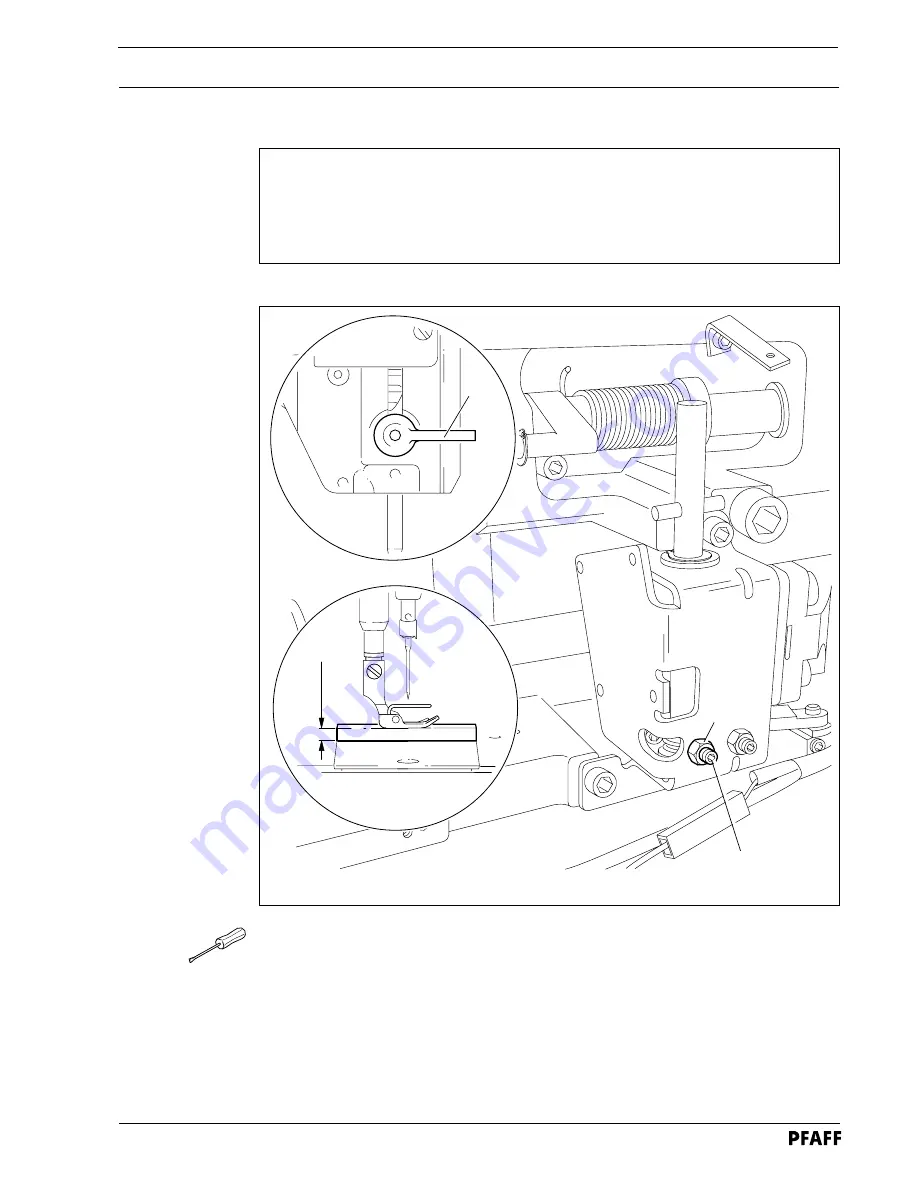

Adjustment

11 - 19

11

.05.17

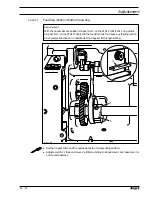

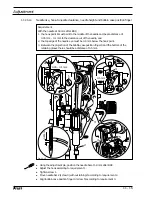

Knee lever stop

Requirement

When the knee lever is fully actuated,

1. the presser foot must be raised approx.

9 mm

(or approx.

13 mm

for a large needle bar

stroke) above the needle plate, and

2. lever

3

must swing down automatically.

●

Loosen nut

1

and unscrew screw

2

a few turns.

●

Raise the presser foot and slide a

9 mm

(for small needle bar stroke) or

13 mm

(for large

needle bar stroke) thick spacer under the presser foot.

●

Swing down lever

3

●

Move the knee lever until it is fully actuated. The presser foot must remain on the

spacer.

●

Now turn screw

2

as far as it will go.

●

Turn screw

2

a half turn back and tighten nut

1

.

1

2

Fig. 11 - 18

3

9 or 13 mm