Adjustment

8

13

.04.03

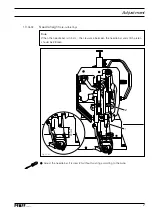

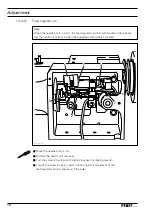

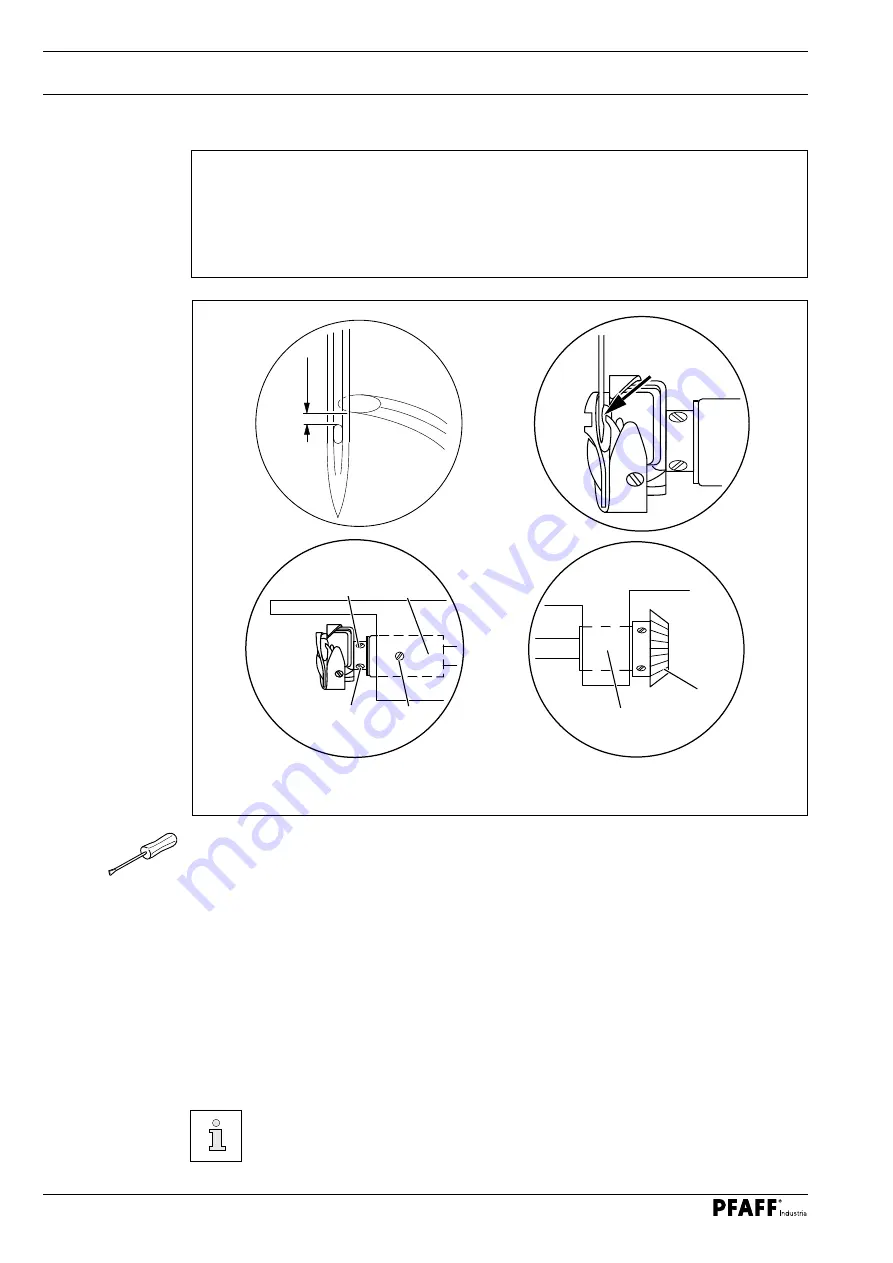

Hook-to-needle clearance, needle bar rise, needle height and needle guard

Rule

With the needle rise positioned

1.8 mm

after b.d.c. of the needle bar:

1. the hook point should be at the needle midpoint and have a clearance of

0.05

to

0.1 mm

to the needle.

2. the upper edge of the eye of the needle should be

0.8 mm

under the tip of the hook.

O

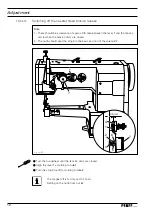

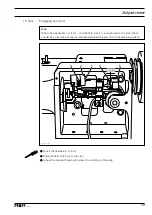

Loosen screws

1

and

2

(screw

2

is located on the back of the machine).

O

Move the needle bar to b.d.c. and slide the

1.8 mm

thick feeler gauge with its cutout

tightly under the lower needle bar bearing. Move the screw clamp so that it touches the

feeler gauge and tighten it.

O

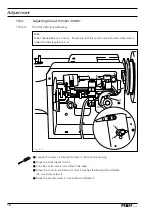

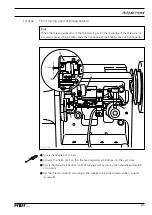

Remove the feeler gauge and turn the handwheel in the direction of rotation until the

screw clamp rests on the needle bar bearing

O

Adjust the hook on the hook shaft according to

rule

1

O

Turn the hook according to

rule

2

(readjust the needle height if necessary), see chapter

13.04.02 Needle height (pre-calibrating)

.

O

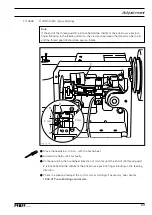

Move the hook shaft bearing

3

until it abuts the hook and tighten the screw

2.

O

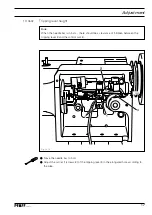

Move the bevel gear

4

until it abuts the bearing

5

and tighten the screws

1.

The setting of the end play of the hook shaft and hook shaft bearing

3

is

omitted in machines with thread trimmer -

900/51.

Fig. 13 - 03

1

2

1

3

5

4

0.05 - 0.1 mm

0.8 mm

Summary of Contents for 333-712/02

Page 29: ...Notes...