Adjustment

13 - 31

13

.07.11

Catch spring

Requirement

When the thread trimmer is in the resting position, there should be a distance of

0.5 mm

between catch spring

1

and roller lever

3

.

24V = 4% ED

3

2

1

0.5 mm

Fig. 13 - 30

●

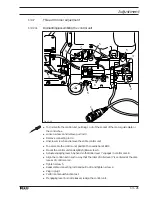

Mount catch spring

1

together with the cover disk.

●

Slightly tighten screws

2

.

●

Push up catch spring

1

as far as it will go and align according to the

requirement

.

●

Tighten screws

2

.