12 - 5

Adjustment

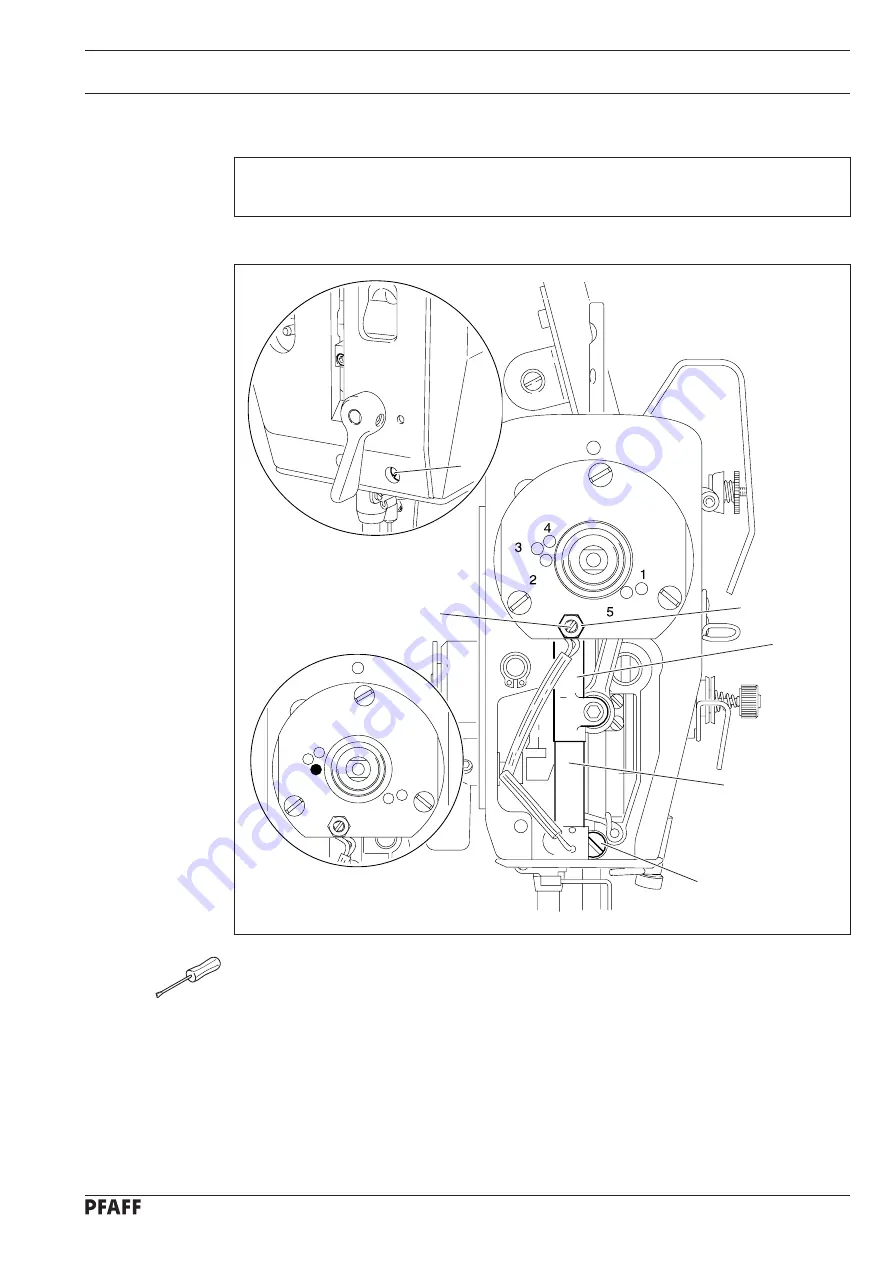

Fig. 12 - 04

6

5

4

3

1

81-018

81-019

4

2

5

1

3

2

●

Bring the needle bar to tdc (hole 2).

●

Loosen screws

1,2

and nut

3

.

●

The largest eccentricity of pin

4

must be facing downwards.

●

Bring the groove on guide bar

5

into a position in which it rests against eccentric pin

4

,

turn eccentric pin

4

in accordance with the

requirement

and tighten nut

3

.

●

Push guide bar

5

downwards and then upwards as far as possible. Bushing

6

must not

move laterally during this movement (readjust eccentric pin

4

if necessary).

●

Move guide bar

5

until it rests against eccentric pin

4

and tighten screws

1

and

2

.

12

.05.03

Parallel guiding of the needle bar

Requirement

Guide bar

5

must be parallel to the needle bar.

Summary of Contents for 3704-2/02

Page 28: ...8 4 Installation and commissioning 8 04 Table top cutout for the PFAFF 939 U ...

Page 115: ...14 3 91 191 477 95 Part 1 Version 05 11 03 Circuit diagrams PFAFF 939 U ...

Page 116: ...14 4 Circuit diagrams Version 05 11 03 91 191 477 95 Part 2 PFAFF 939 U ...

Page 117: ...14 5 91 191 477 95 Part 3 Version 05 11 03 Circuit diagrams PFAFF 939 U ...

Page 118: ...14 6 Circuit diagrams Version 03 09 04 91 191 487 95 Part 1 PFAFF 3704 ...

Page 119: ...14 7 91 191 487 95 Part 2 Version 03 09 04 Circuit diagrams PFAFF 3704 Fadenwischer ...

Page 120: ...14 8 Circuit diagrams Version 03 09 04 91 191 487 95 Part 3 PFAFF 3704 ...

Page 121: ...Notes ...