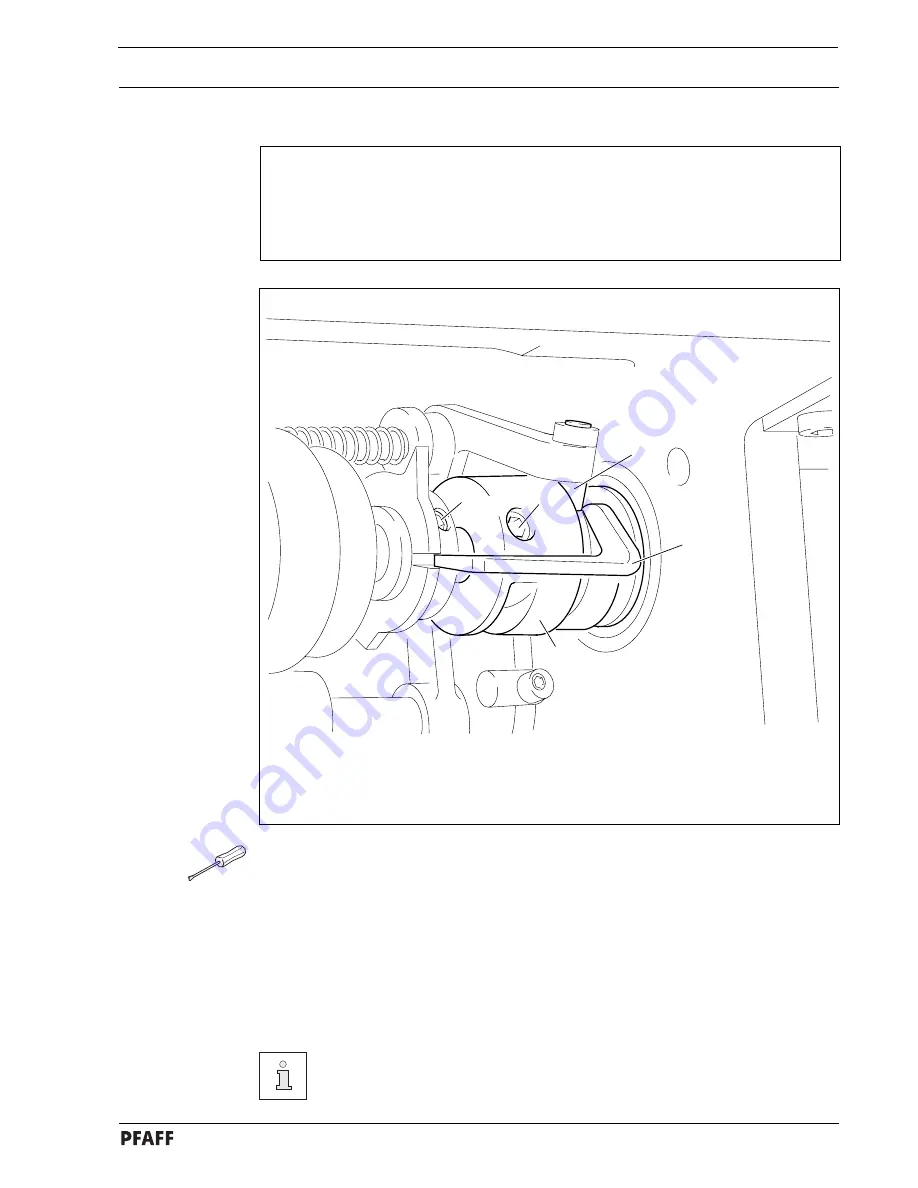

Adjustment

12 - 27

12.

05.06

Control cams to the bobbin opener and cutter

( adjustment with adjustment gauge )

Requirements

With the needle bar at BDC, both control cams must be positioned in such a way that

1. adjustment gauge

5

can be slid into the grooves of both control cams,

2. both cams are on the rests of adjustment gauge

5

and

3. the bent section of adjustment gauge

5

is touching roller

3.

1

2

4

5

3

Fig. 12 - 23

●

Loosen screws

1

and

2.

●

Bring the needle bar to BDC and activate the tripping lever by hand ( roller

3

engaged ).

●

Adjust the control cams in accordance with the

requirement

and insert adjustment

gauge

5

.

●

Turn control curve

4

in accordance with the

requirement.

●

Taking care to ensure that control cam

4

is touching the bearing collar, tighten the

accessible screws

1

and

2

.

●

Remove adjustment gauge

5

and tighten the remaining screws

1

and

2

.

For adjustment without the gauge see chapter

12.05.07 Radial position of the

control cam in relation to the bobbin opener

and

chapter 12.05.08 Control

cam in relation to scissor.