Set-up and Initial Commissioning

23

8

.03

Initial start-up

Inspect the machine and in particular the

electric lines and pneumatic connecting

hoses for possible damage.

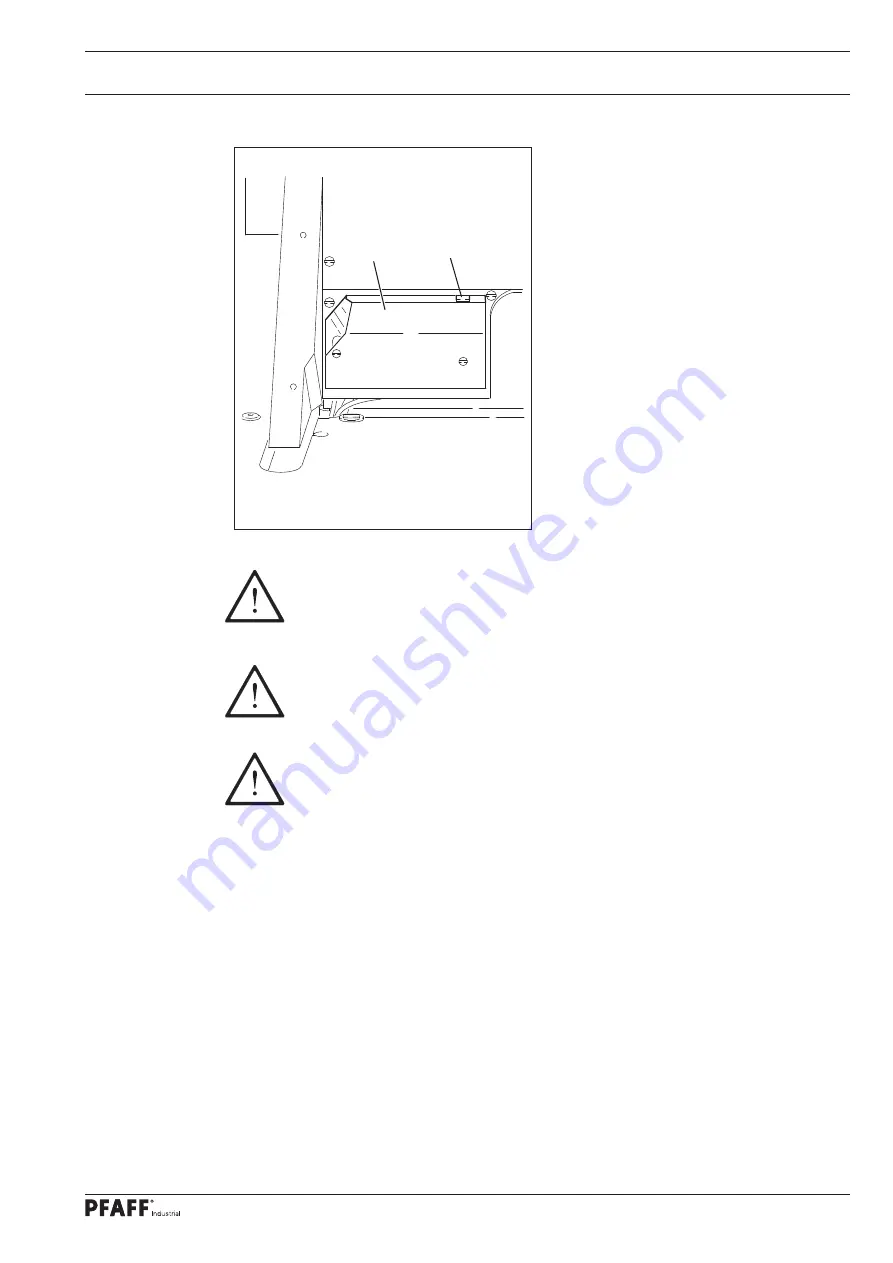

Remove the stopper

1

from the oil tank

2

. The stopper serves solely for transit

support and may not be used during the

sewing operations.

Clean the machine thoroughly

and then oil it, see

Chapter 10

Maintenance and Care

.

Have technical staff check whether the

machine´s motor may be operated at the

existing mains voltage.

Never operate the machine if there are any differences.

Before the initial commissioning, have technical staff verify

that parameter

201

(machine class) is set to "

1

".

The machine must only be connected to a grounded socket!

Connect the machine to the compressed air system. The manometer should display

a pressure of around

6

bar. Set this value if required

(see Chapter

10.04 Checking / setting the air pressure

).

8

.04

Switching the machine on/off

Switch the machine on, see Section

7.01 Main switch.

Fig. 8 - 04

2

1