4 PFAFF

47

Automatic backtacking system ...................................................................................... 44

48

Stitch condensation system ........................................................................................... 44

49

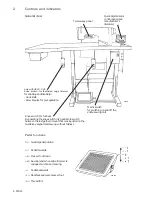

Edge trimming system ................................................................................................... 46

.1

Trimming movement ...................................................................................................... 46

.2

Neutral point .................................................................................................................. 46

.3

Knife height .................................................................................................................... 46

.4

Positioning the top knife in sewing direction ................................................................. 46

.5

Positioning the top knife crosswise to sewing direction ................................................ 46

.6

Adjusting the stop eccentric .......................................................................................... 46

50

Step-cut trimming mechanism ....................................................................................... 50

.1

Note on motor control .................................................................................................... 50

.2

Preparations for adjusting the trimmer .......................................................................... 50

.3

Setting the longest knife stroke ..................................................................................... 50

.4

Setting the top reversal point of the knife ...................................................................... 50

.5

Positioning the top knife bracket and front top knife according to the needle

plate ............................................................................................................................... 52

.5.1 Cutting angle of the front top knife ................................................................................ 52

.5.2 Cutting position of the front top knife ............................................................................ 52

.5.3 Cutting pressure of the front top knife ........................................................................... 52

.6

Neutral point of top knife movement ............................................................................. 54

.7

Setting top knife at highest point ................................................................................... 54

.8

Positioning the rear top knife and hook knife ................................................................. 54

.8.1 Lateral position of the rear top knife to hook knife ......................................................... 54

.8.2 Cutting angle of the rear top knife in relation to the hook knife ..................................... 56

.8.3 Cutting pressure between rear top knife and hook knife ............................................... 56

.8.4 Setting the cutting depth of the rear top knife in relation to the hook knife ................... 58

.9

Settng the cutting depth of the front top knife .............................................................. 58

.10

Setting the trimming margin .......................................................................................... 58

.11

Basic adjustments on the top knife mounting ................................................................ 60

.11.1 Cutting angle of the rear top knife ................................................................................. 60

.12

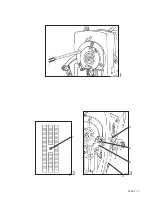

Sensor controlled monitoring of the hook knife ............................................................. 62

.12.1 Function ......................................................................................................................... 62

.12.2 Sensor adjustment ......................................................................................................... 62

.12.3 Fault finding and remedy ................................................................................................ 64

51

Airblast for ply separation .............................................................................................. 66

52

Airblast for cutting waste ............................................................................................... 66

53

Differential quick adjusting device for altering the fullness ............................................ 68

.1

Zeroing the rapid differential adjustment ....................................................................... 68

.1.1 Rough adjustment on the angle encoder ....................................................................... 68

.1.2 Precise adjustment on pot "0" ........................................................................................ 68

.2

Key arrangement to set pointer 1 .................................................................................. 70

.2.1 Key "0" and "1 to 4" ......................................................................................................... 70

.2.2 Keys "5 to 7" ................................................................................................................... 70

.3

Basic setting of the fullness quantities of keys "1 to 7" .................................................. 70

.3.1 Adjustment of fullness key "1" ....................................................................................... 70

.3.2 Adjustment of fullness key "2" ....................................................................................... 70

.4

Feed lever ...................................................................................................................... 72

.5

Sample adjustment of the potentiometer ...................................................................... 74

54

Care and maintenance ................................................................................................... 76

.1

Sewing machine ............................................................................................................ 76

.1.1 Oiling the sewing machine ............................................................................................. 76

.1.2 Cleaning the sewing machine ........................................................................................ 76

.2

Air filter/lubricator ........................................................................................................... 76

.2.1 Water trop bowl ............................................................................................................. 76

.2.2 Air filter .......................................................................................................................... 76

.3

Recommended lubricants .............................................................................................. 77

only on 3822-1/22

only on 3822-1/24

Summary of Contents for 3822-1/22

Page 9: ...PFAFF 9 1 1 2 3 WARTEIN CDR 1 Kap03 2N 2 3 4 ...

Page 11: ...PFAFF 11 1 KAP10 04 2 3 1 2 ÖL N ...

Page 13: ...PFAFF 13 KAP07 1N KAP07 2N 2 1 1 1 2 3 5 6 4 ...

Page 15: ...PFAFF 15 1 2 KAP13 02 2 4 3 KAP12 03 3 5 1 KAP08 04 ...

Page 17: ...PFAFF 17 02 01 2 4 3 1 3 2 5 02 02 1 01 01 5 mm ...

Page 21: ...PFAFF 21 1 1 1 1 1 KAP05 00 1 2 4 KAP08 04 4 5 2x 4 3 KAP08 04 3 2x 2 17 2N ...

Page 25: ...PFAFF 25 KAP29 05 2 1 2 Lehrenfuß Best Nr 61 111639 20 1 3 3 4 0 5 mm 6 5 4 KAP30 05 ...

Page 31: ...PFAFF 31 KAP13 01 1 2 1 2 3 4 KAP29 05 3 6 5 ...

Page 33: ...PFAFF 33 2 1 KAP03 01 1 2 3 2x KAP17 01 0 3 mm 7 2x 4 5 3 6 KAP17 2N ...

Page 39: ...PFAFF 39 2 KAP01 X1 1 2 0 5 mm KAP45 01 1 5 7 mm 4 KAP48 02 1mm KAP47 01 8 3 1 0 9 7 6 5 3 4 ...

Page 41: ...PFAFF 41 KAP32 01 2 6 5 KAP29 05 1 3 4 2 1 12 mm ...

Page 43: ...PFAFF 43 KAP52 01 3 KAP32 01 2 KAP52 02 5 8 1 0 1 7 1 1 1 2 1 3 3 9 6 2 4 1 3x ...

Page 45: ...PFAFF 45 6 4 KAP54 01 1 3 9 8 5 1 10 2x 7 BI 02N 2 KAP31 02 KAP10 01 2 3 ...

Page 47: ...PFAFF 47 1 5 05 00 4 3 56 04 9 1 0 5 0 5mm 56 xx 56 01 1 2 3 4 5 7 8 6 2 ...

Page 51: ...PFAFF 51 2 KAP56 01 3 6 5 4 KAP33 02 1 1 2 3 ...

Page 53: ...PFAFF 53 KAP56 02 4 8 7 KAP33 02 5 1 2 9 10 11 12 1 3 7 1 0 9 max 0 1mm 6 10 9 ...

Page 55: ...PFAFF 55 8 15 14 17 KAP56 01 9 16 20 1 1 7 8 12 KAP33 02 9 1 0 18 2 0 ...

Page 61: ...PFAFF 61 21 7 26 8 27 28 ...

Page 63: ...PFAFF 63 23 3 5 33 35 3 4 20 22 29 30 31 3 2 3 6 3 6 Sensor1 ...

Page 65: ...PFAFF 65 2 6 37 2 5 2 4 38 39 20 32 31 ...

Page 67: ...PFAFF 67 KAP57 01 2 1 1 6 5 KAP33 02 3 2 3 4 2 BI 02N ...

Page 69: ...PFAFF 69 4 1 2 3 3 4 2 1 918 15N 5th graduation on scale zero position ...

Page 71: ...PFAFF 71 5 7 6 1 918 15N ...

Page 73: ...PFAFF 73 10 01 1 2 6 6 6 5 7 918 15x 9 1 0 9 7 8 8 918 15N 1 0 1 1 ...

Page 75: ...PFAFF 75 1 4 1 3 ...