19

Adjustment

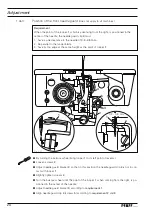

Fig. 1 - 12

1

.05.12

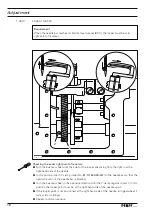

Looper-to-needle clearance in sewing direction

Requirement

In sewing direction there must be a cleaance of approx.

0.1 mm

between looper point

and needle.

●

Turn the balance wheel until the looper point coming from the right reaches the left side

of the needle.

●

Align looper unit

1

(screw

2

) according to the

requirement

.

If a clearance of

0.1 mm

cannot be obtained, the setting of the eccentric bea-

ring stud

3

can be corrected. In this case the looper height and angle must be

checked, see

Chapter 1.05.11 Looper height and looper angle.

1

2

2

2

0,1 mm