GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

Subject to technical modifications

Design changes under reserve

Sous réserve de modifications techniques !

10

4.3.2 HSE for explosive-atmosphere zones in acc. with 2014/34/EC (ATEX)

Model series HSE unit size

36.1

50.1

63.1

80.1

100.1

125.1

140

200.1

Max. lifting force

[kN]

10

25

50

100

200

350

500

1000

Max. tension

[kN]

10

25

50

100

178

350

500

1000

Screw Tr6

24x5

40x8

50x9

60x12

70x12

100x16 120x16

160x20

Ratio N

5:1

6:1

7:1

8:1

8:1

10 2/3:1 10 2/3:1 13 1/3:1

Lift per rotation at ratio N

[mm/U]

1,0

1,33

1,28

1,5

1,5

1,5

1,5

1,5

Ratio L

20:1

24:1

28:1

32:1

32:1

32:1

32:1

40:1

Lift per rotation at ratio L

[mm/U]

0,25

0,33

0,32

0,375

0,375

0,5

0,5

0,5

Max. drive capacity at 20°C ambient

temperature and 20% DC/h

[kW]

0,45

0,75

1,2

1,8

2,4

3,8

5,5

9

Max. drive capacity at 20°C ambient

temperature and 10% DC/h

[kW]

0,9

1,5

2,3

3,6

4,8

7,7

10,2

17,9

Overall efficiency ratio N

[%]

See efficiency table compendium worm gear screw jack

Overall efficiency ratio L

[%]

See efficiency table compendium worm gear screw jack

Spindle efficiency

[%]

43

40

36,5

39,5

35,5

34

30

28,5

Torque-capacity-rotation speed at 20% ID/hr.

and 20°C

See power table compendium on worm gear screw jacks

Screw torque at max. lifting force

[Nm]

18,4

80

190

478

1060

2600

4235

11115

Max. permit. torque on the drive shaft

[Nm]

29,4

48,7

168

398

705

975

1640

4260

Max. permit. screw length at pressure load

[mm]

See offset diagram compendium worm gear screw jacks

5

Receipt of goods, storage, transport

5.1

Receipt of goods

Startup with defective screw jacks is forbidden.

Immediately check if the contents of delivery correspond with the shipping documents upon receipt. No

other warranties can be approved for subsequent defect claims.

Claims on defects and incompleteness are to be made immediately at Pfaff-silberblau.

Claims on perceivable damages due to transport are to be reported to the transport company immediately.

Small parts such as limit switches are usually delivered unattached and packed individually.

5.2

Transport

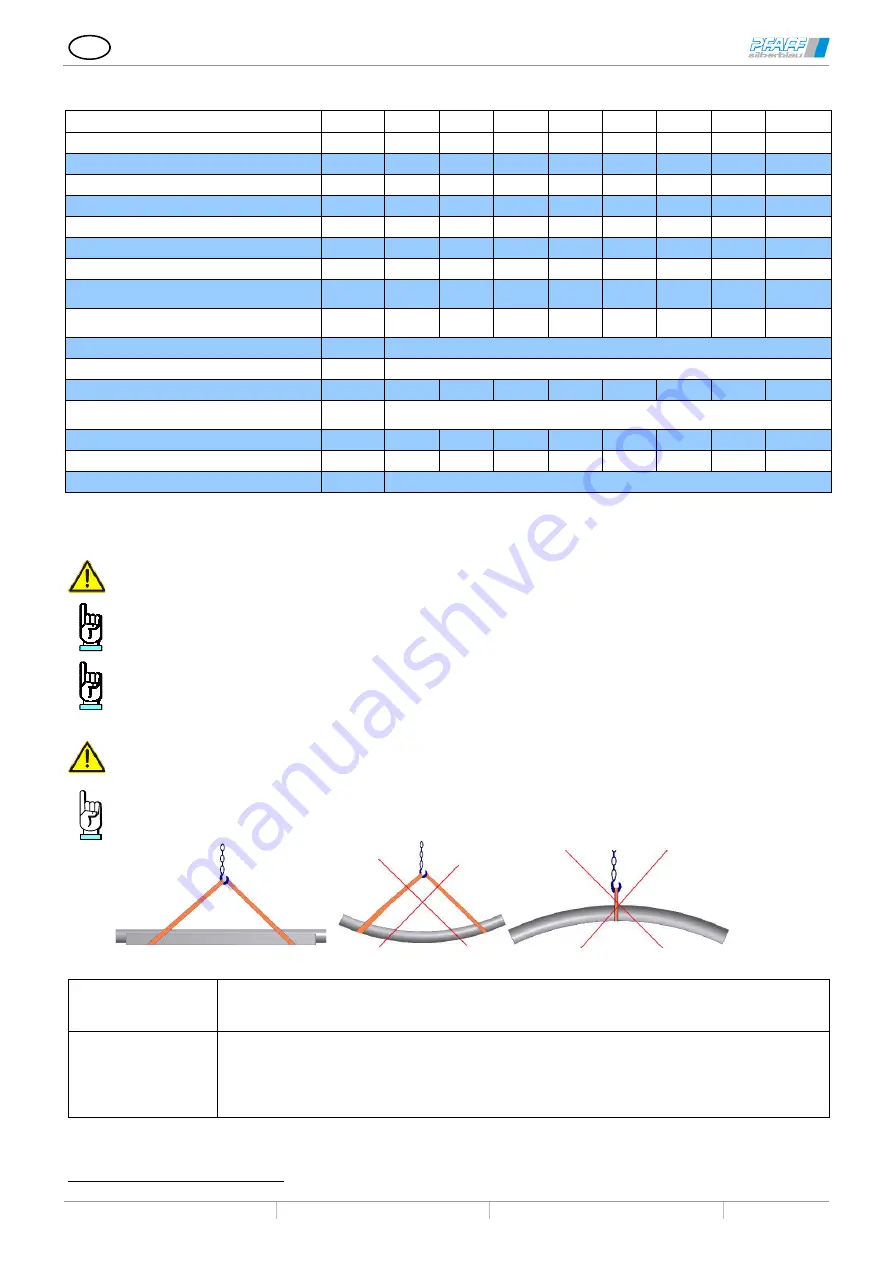

Lift / transport the screw jack by the appropriate hoisting points.

Pay attention to the attachment parts. No person is to stand under suspended loads.

Use hoisting gear in good condition.

Keep long screws from getting warped. Support screw by appropriate means.

5.3

Storage

Storage period

< 3 years

Check corrosion protection; renew or repair, if necessary.

Check lubrication of moveable machinery, relubricate if necessary.

Check oil level of gears; refill, if necessary.

Storage period

> 3 years

Check corrosion protection; renew or repair, if necessary.

Check lubrication of moveable machinery, relubricate if necessary.

Clean spindle and grease with fresh lubricant along the whole length.

Drain gear oil, and fill gear unit with the prescribed oil quantity and quality. Regrease for

grease lubrication.

6

Also with Ku screw