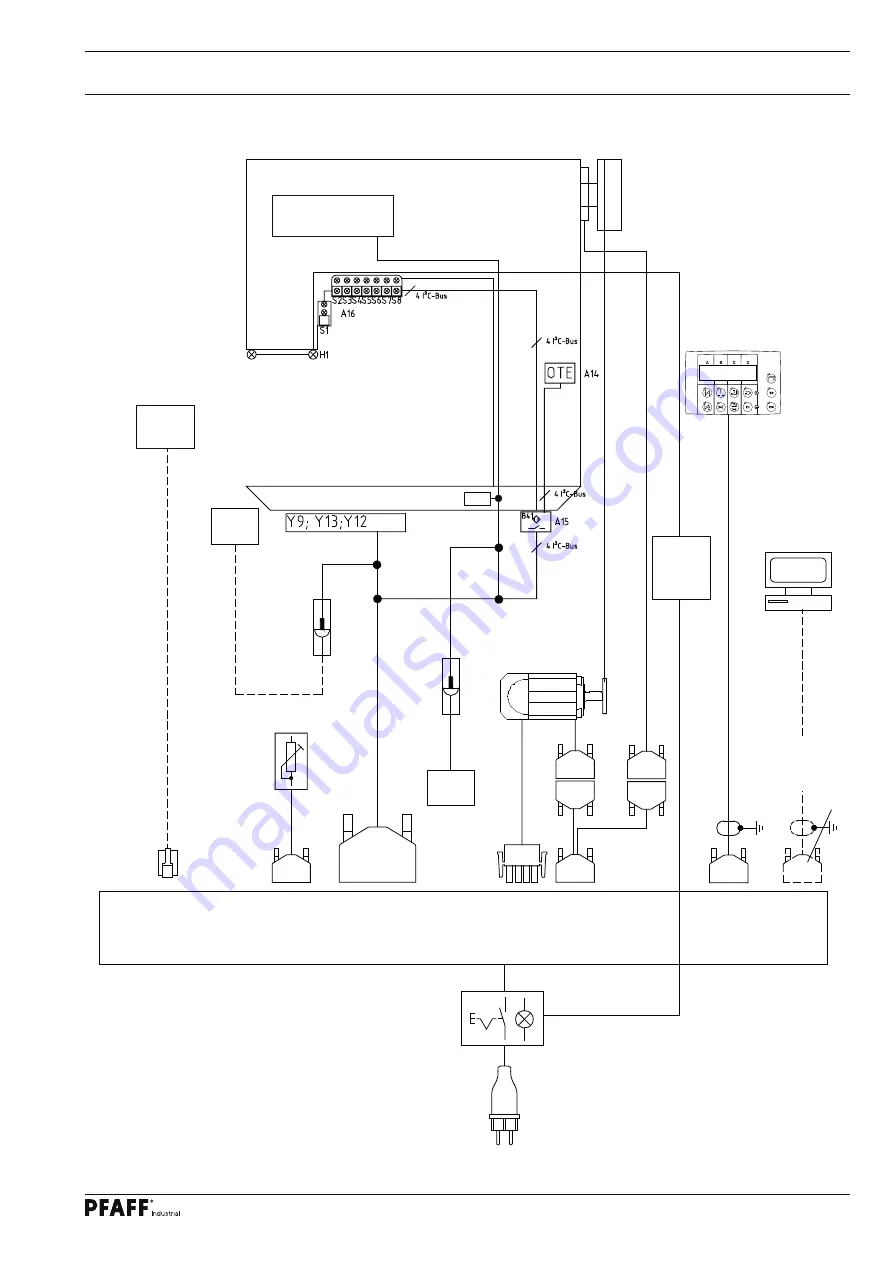

27

A2

A20

XA20

XS27

XS29

X7

X3

X5

X1

X2

X0

X4

X2

X2.1

X2.2

X2.2

S1.1

KS

Y3, Y4, Y5, Y6, Y9

Y8, Y14, Y1X, R1

PC

S26

4

.16

Block diagram PFAFF 2595/96 PLUS with EcoDrive P74 ED-L

Synchronizer PD 6

for

software

download

Q1

Power switch

Mains plug

Control unit P74 ED

A1

Optional

Option

BDF - PICO TOP

Light

barrier

2595 PLUS

2596 PLUS

Installation

Ministop drive

unit (long) with

incremental

transducer

LED

power

supply

unit