Adjustment

95

4

.06.05

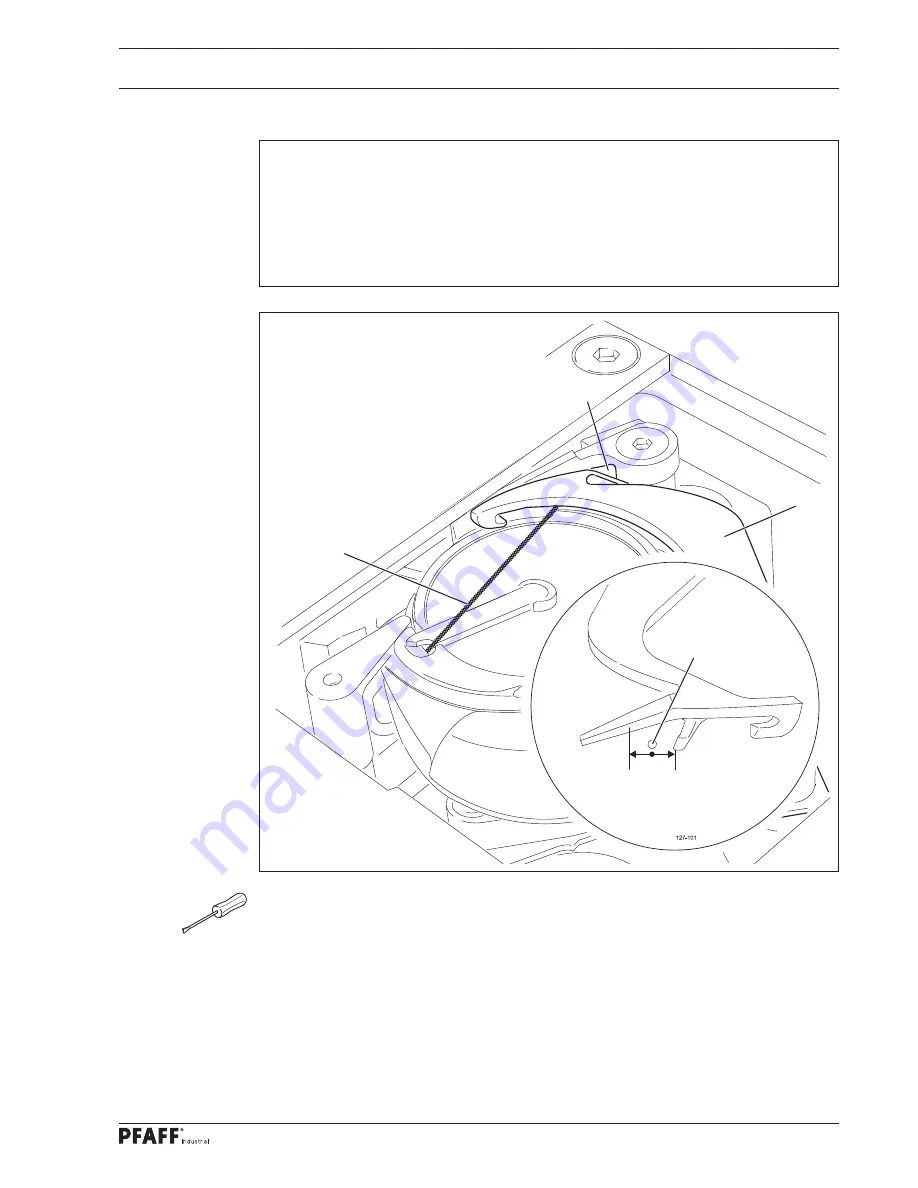

Manual cutting test

Requirement

1. When moving forward, thread catcher

1

must not move bobbin thread

3

2. When thread catcher

1

is at its front point of reversal, bobbin thread

3

should be in the

centre of the marked area (see arrow).

3. After the cutting operation has been completed, needle and bobbin thread should be

cut neatly and bobbin thread

3

should be held.

●

Sew a few stitches.

●

Switch of the main switch and the compressed air.

●

Carry out a manual cutting test.

●

Check requirement

1

. If necessary, readjust thread catcher

1

in accordance with Chapter

4

.

06

.

02

Position and height of the thread catcher.

●

Check requirement

3

. If necessary, readjust bobbin thread clamp spring

2

in accordance

with Chapter

4

.

06

.

04

Bobbin thread clamp spring.

Fig. 4 - 19

1

2

3

3

Summary of Contents for POWERLINE 3741

Page 1: ...296 12 19 008 002 Betriebsanleitung engl 06 12 DOKU SEAM SYSTEM 3741 3745 ...

Page 7: ...Register 01 ...

Page 8: ......

Page 14: ......

Page 15: ...Register 02 ...

Page 16: ......

Page 43: ...Register 03 ...

Page 44: ......

Page 81: ...Register 04 ...

Page 82: ......

Page 126: ......

Page 127: ...Register 05 ...

Page 128: ......

Page 129: ...Kalibrieranleitung engl 06 12 CALIBRATION INSTRUCTIONS 3741 3745 ...

Page 139: ...Register 06 ...

Page 140: ......

Page 147: ...135 91 191 528 95 Part 1 Version 12 01 12 Circut diagrams ...

Page 148: ...136 Circut diagrams Version 12 01 12 91 191 528 95 Part 2 ...

Page 149: ...137 91 191 528 95 Part 3 Version 12 01 12 Circut diagrams ...

Page 150: ...138 Circut diagrams Version 12 01 12 91 191 528 95 Part 4 ...

Page 151: ...139 91 191 528 95 Part 5 Version 12 01 12 Circut diagrams ...

Page 152: ...140 Circut diagrams Version 12 01 12 91 191 528 95 Part 6 ...

Page 153: ...141 91 191 528 95 Part 7 Version 12 01 12 Circut diagrams ...

Page 154: ...142 Circut diagrams Version 05 01 12 91 191 536 95 ...

Page 155: ...143 91 191 536 95 Version 12 01 12 Circut diagrams ...