Page 15

Inserting (or changing) the Needle

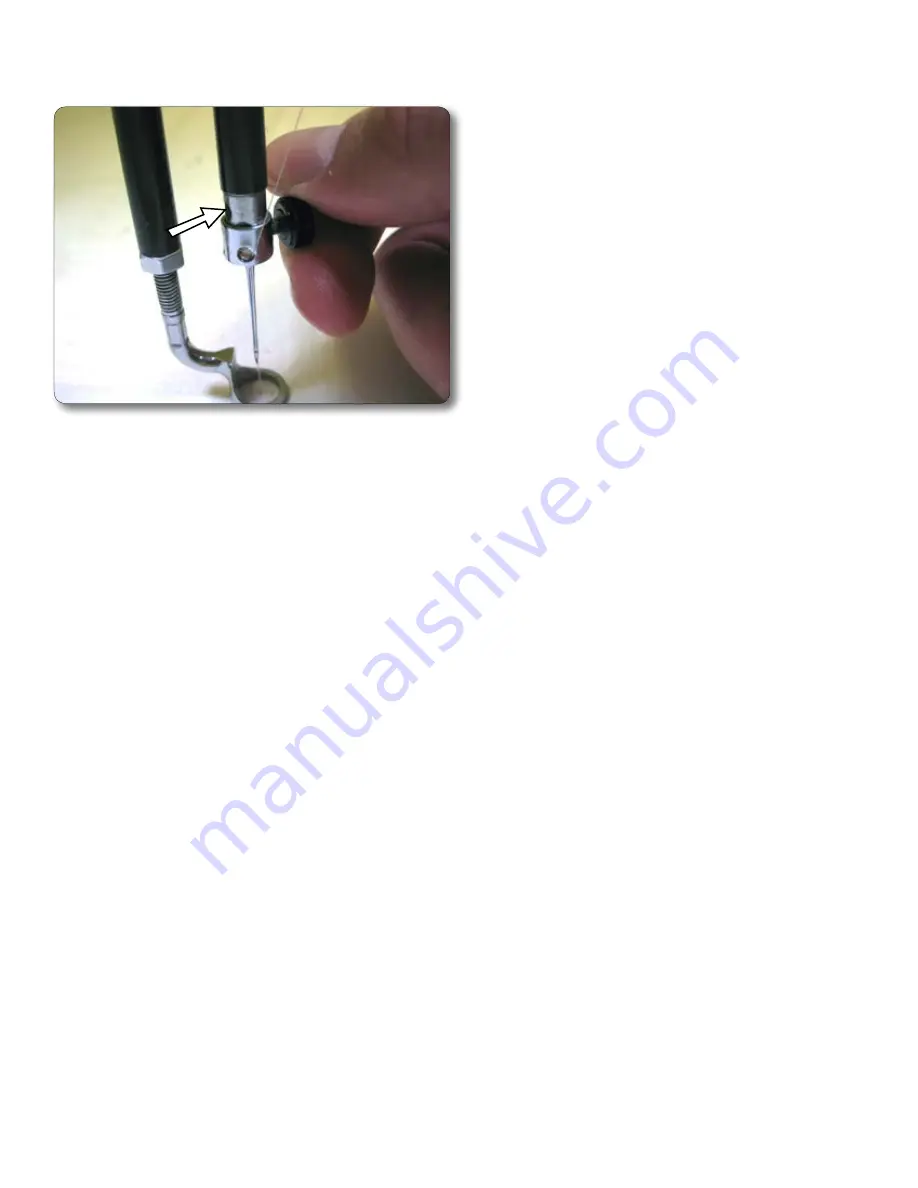

Figure 7

The needle that is in the machine when it arrives at

your home has been used for 20 minutes of testing.

It is possible that it could be damaged in shipping or

as you remove the machine from the box. For these

reasons, we recommend that you replace the needle

before beginning to quilt with your new machine.

1. Move the needle bar to the highest position by

turning the hand wheel.

2. Confirm that the power is off and that the machine

is unplugged.

3. Loosen the needle-bar clamp thumb screw (see

Figure 7) enough to assure that the needle can be

inserted all the way up to the top of the sight hole.

4. With the scarf (small ground out section/dip on

the back side of the needle just above the needle eye)

facing the hand wheel end of the machine, and the

long groove down the front of the needle facing the

bobbin case side (see Figure 7), push the needle all

the way up into the needle bar – until it can go no

further. Look into the sight hole to verify that the butt of

the needle reaches the top of the sight hole.

5. Carefully tighten the thumb screw. Over-tightening

the thumb screw will result in damaged threads or

stripping of the screw hole. Stripped holes are not

covered under warranty. To avoid over-tightening the

screw, finger-tighten only.

The foot is adjusted at the factory and should not be

moved without consulting your dealer.

Adjusting the Hopping Foot

SIGHT

HOLE

Note:

Changing the needle is recommended for each

new quilt loaded on the machine or any time the needle

becomes bent, dull or burred.

Needles are inexpensive and are important to the

success of your project. Plan to change needles every

5-7 hours of quilting or more often if working with a lot

of fusibles or heavy materials.

Needle/Thread Selection Guide

Needle Size

14 (90)

16 (100)

18 (110)

20 (120)

Threads

Silk (100 wt) 60 wt., monofilament,

glitter, some metallics

60 wt., 50 wt., 40 wt., monofilament,

glitter, metallics

50 wt., 40 wt., 30 wt., metallic

30 wt., 20 wt., 12 wt.