Page 16

1. Place a cone or spool of thread on the spool pin.

If using a spool, make sure that the slits on the spool

are against the base of the spool pin holder. Pass the

thread through the thread-stand eyelet from back to

front, continuing to thread guide A. (Figure 8)

2. Continue to the three-hole thread guide B.

Beginning at the top, wrap all three holes from back to

front, hand wheel side to needle side (see Figure 9).

Note:

The purpose of the three-hole thread guide B is to

prevent loops of thread coming off the thread cone from

going into the top tension as a knot can cause thread

breakage and bad tension. For most threads on a cone,

it is important to thread all three holes for consistent

results and to make adjustments at the top tension

assembly. An exception to this rule is when working with

very delicate threads, such as holographic or threads

that are prone to breakage. You may try skipping one or

two holes on thread guide B when using these threads.

Figure 8

Figure 9

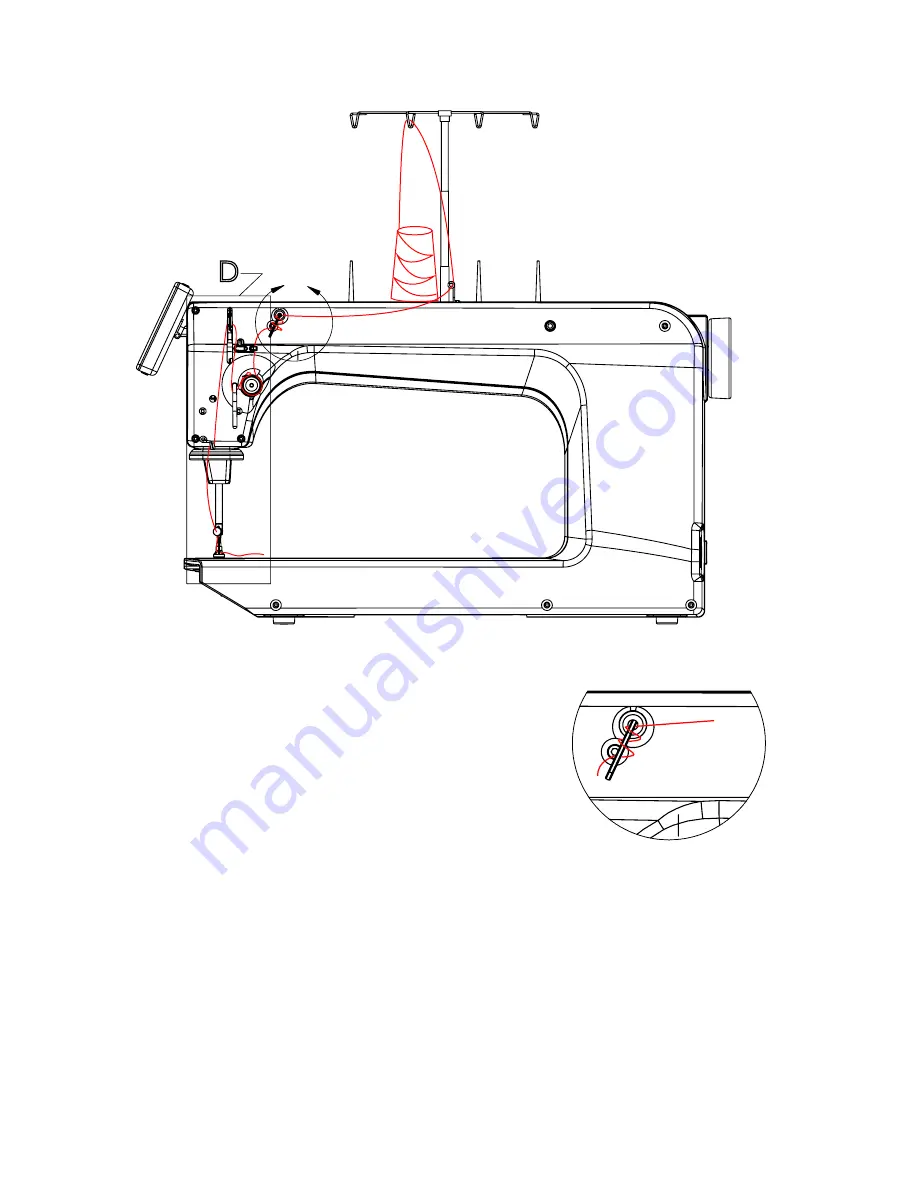

Threading the Machine

G

D

C

DETAIL D

SCALE 1 : 2

DETAIL G

SCALE 1 : 2

DETAIL C

SCALE 1 : 2

A

G

D

C

DETAIL D

SCALE 1 : 2

DETAIL G

SCALE 1 : 2

DETAIL C

SCALE 1 : 2

B