19

Prepar

ations

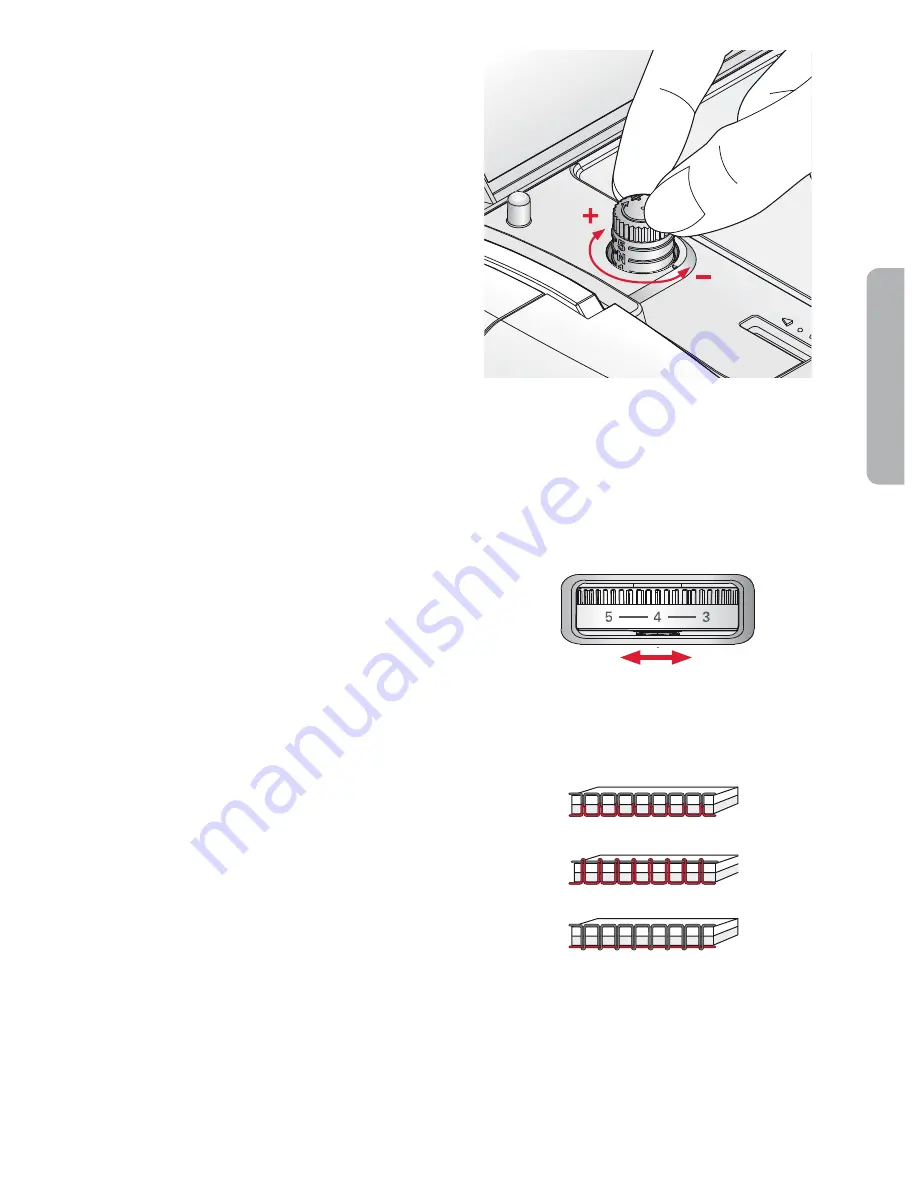

Presser foot pressure

The presser foot pressure has been pre-set to the

standard value ”N”. In most cases, you do not need

to adjust the presser foot pressure. When using

specialty techniques, or when sewing on very light

or heavy fabric, adjusting the pressure can improve

the result.

For very light fabrics, loosen the pressure by

turning the dial counterclockwise.

Note: If the dial is turned counterclockwise too much, it

could come off. If this happens, simply replace the dial

and turn it clockwise until it stays in place.

For heavy fabric, tighten the pressure by turning

the dial clockwise.

Note: If the dial is turned clockwise until it comes to a

stop, it has reached the maximum pressure available. Do

not try to turn the dial any further!

Thread tension

To set the thread tension, turn the dial on top of

the machine. Use the recommended thread tension

setting given on the screen, see page 29. Depending

on the fabric, batting, thread, etc, the tension may

need to be adjusted.

For the best stitch appearance and durability, make

sure the needle thread tension is correctly adjusted.

For general sewing, the threads evenly meet

between the two layers of fabric.

If the bobbin thread is visible on the top side of

the fabric, the needle thread tension is too tight.

Reduce the needle thread tension.

If top thread is visible on the underside of the

fabric, the needle thread tension is too loose.

Increase the needle thread tension.

For decorative stitches and buttonholes, the top

thread should be visible on the underside of the

fabric.

Make a few tests on a scrap piece of the fabric you

are going to sew and check the tension.

Summary of Contents for quilt ambition 2.0

Page 1: ...Owner s manual ...

Page 4: ......

Page 12: ...12 Introduction Alphabets Block letters Outline letters Script letters Cyrillic letters ...

Page 26: ...26 Preparations ...

Page 45: ...45 Maintenance ...

Page 46: ......