English

Service Jack SILVERLINE HRH S

F 06.01.175

technische Änderungen vorbehalten

design changes under reserve

changements techniques sous réserve

10 / 12

Inspection and servicing guide

Safety Instruction

Always ensure that hydraulic jack pressure is fully released BEFORE carrying out inspection or

maintenance work.

Inspection intervals

Maintenance and inspection tasks

Visual check of head section

Check jack for correct functioning

Check for leaks

Daily and/or before each

jacking operation

Cleaning and degreasing of moving parts

Cleaning and lubrication of moving parts

Twice a year

If the jack is used only occasionally, pump the lifting piston up to its full extent and then release

once more.

Check oil level

Check all parts of the jack for damage and replace any component that shows signs

of wear

Check identification plate for legibility

Yearly

Have check carried out by qualified service technician

1)

Every two years

Carry out oil change

1)

e.g. by Pfaff-silberblau Customer Service

Observe the specified service life of each component. Replace worn parts immediately.

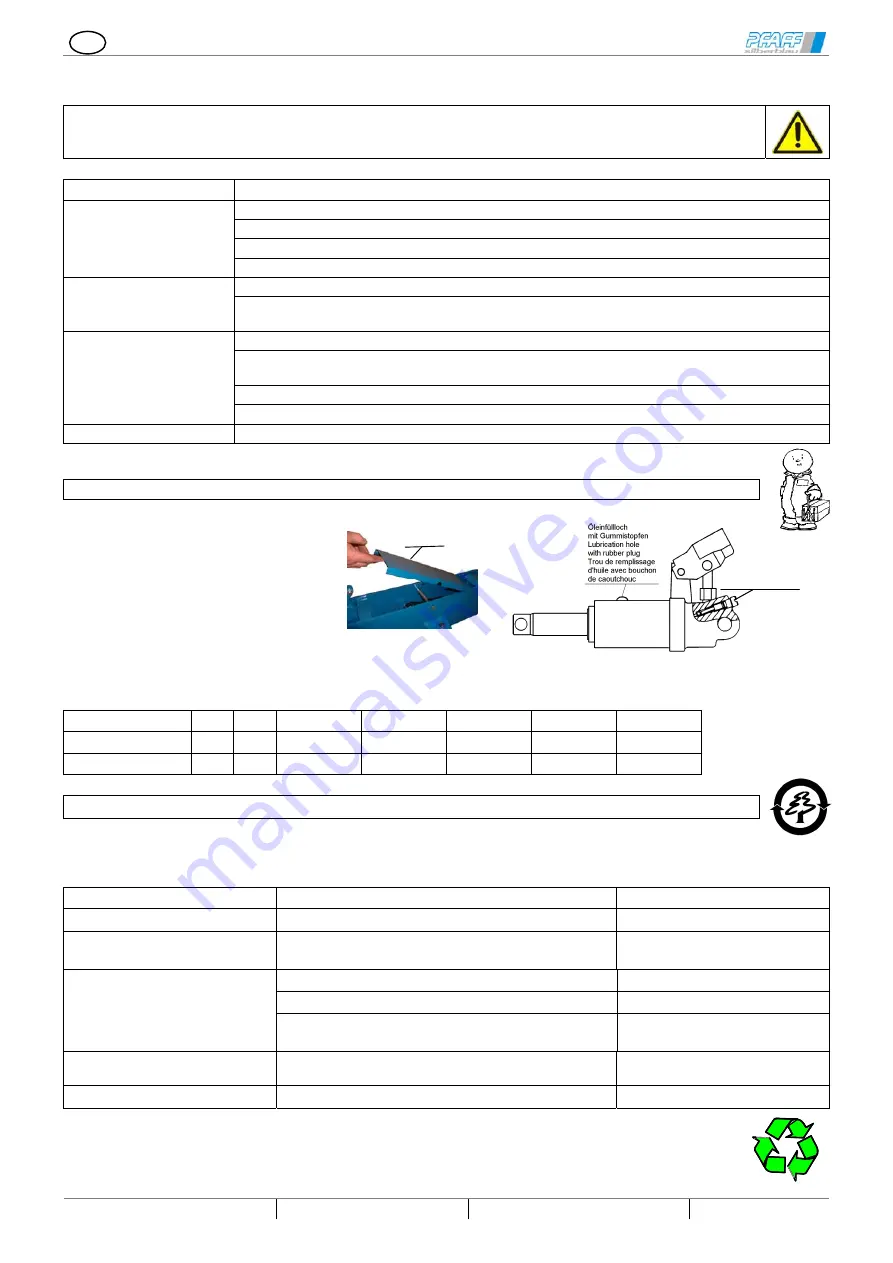

Topping up/changing the oil

Open cover

Open the rubber stopper

Drain off the old hydraulic fluid

Fill with fresh hydraulic fluid

Close rubber stopper

Recommended hydraulic oil:

Hydraulic oil HL 15 (HL 22) DIN 51 524 (ISO VG 15-22)

Keep oil at required level. Clean area around filler-hole BEFORE removing stopper!

HRH S 2,0 K HRH S 2,5 K HRH S 2,0 L HRH S 3,0 L HRH S 5,0 L

040008530

040008531 040008532 040008533 040008534

Oil quantity

[l]

0,115

0,165

0,30

0,27 0,35

Dispose of used hydraulic oil in accordance with relevant waste-treatment regulations

Troubleshooting

If problems occur, do not lift the load any further.

Fault Cause

Remedy

Pump does not deliver pressure

Screw-action release valve open

Shut release valve

Piston fails to move despite

pumping action

Load excessive, pressure limiting valve in operation

Reduce load

Leak in hydraulic system

Carry out required maintenance

Non-return valve fails to close, or valve seat is soiled

Clean or replace

Piston lowers independently of

pump action

Release valve fails to close, or valve-seat seal is

contaminated with oil

Clean or replace

The lifting arm does not fully

extend

Too little oil in the hydraulic system

Check the oil level and top it up if

necessary

Jack losing oil

Worn seals

Fit new seals

Eventual scrapping

When the jack is taken out of service, all components should be recycled or dis-

posed of in accordance with the relevant legislation in force at the time of scrapping.

drain valve

cover