11 685408014B

according to the provisions of 9.ProdSV (German

regulations covering accident prevention).

• PCN has to do the electrical safety testing to every

cooling before delivery.

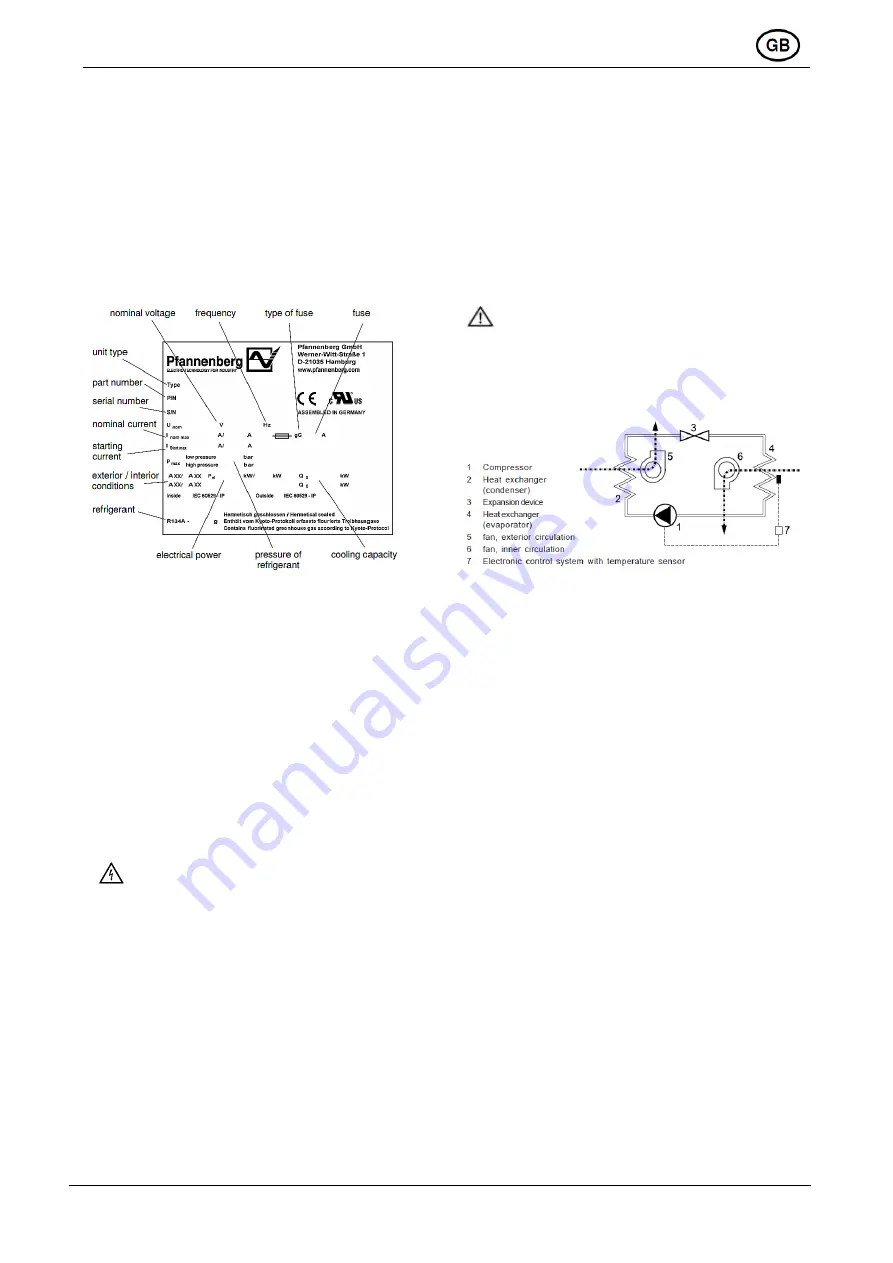

5 Name plate

For the installation and maintenance, please notice the

details technical data on the name plate which to be find

on the back of the cooling unit casing.

6 Safety

Cooling units produced by

Pfannenberg

are designed

for application dissipating heat from switch cabinets (IP

54).

The cooling unit is only suitable for installing on the

stationary operation.

Only the authorized specialist can be work on the cooling

system and electrical components.

Please make sure to comply with relevant safety and

environmental regulations.

Hazard!

Cutting off cooling unit power supply before carrying

out any cleaning or maintenance operations.

Only original spare parts may be used.

7 Function

7.1 Function and configuration

Equipment configuration:

1. High quality key components

2. Protection device for the compressor

3. Intelligent control system

4. Condensate evaporator (optional)

5. 2~Phase 400Vac power supply (optional)

Equipment function:

1.

General

external

environment

temperature:

+15

℃

~+55

℃

2. General inside control temperature: +25

℃

~+45

℃

3.

Start-up self-check and real-time self-check

4. IP54 / IP34 protection class

5. Condensate evaporator (optional)

6. 2~Phases 400Vac power supply (optional)

Caution:

Please refer to the attached technical specification for the

details function of the cooling unit.

7.2 Operating principles

The compressor (1) compresses the refrigerant until high

pressure is achieved. During this process temperature

increases. In the condenser (2) heat is dissipated to

ambient air, the coolant becoming liquid. The condenser

fan (5) of the compensate takes ambient air in through the

condenser, and then it releases the air.

In the expansion valve (3) the pressure of the coolant

drops. In the evaporator (4) the coolant absorbs heat from

the air in the switch cabinet and evaporates. Thus, the air

in the switch cabinet cools down. At the same time the air

inside the switch cabinet is being dehumidified. The

evaporator fan (6) sucks the air out of the switch cabinet

via the evaporator, the cooled air flows back to the switch

cabinet.

The cooling unit is electronically controlled. For that

purpose a temperature sensor records the temperature of

the air inside the switch cabinet (7).

The refrigerant is not detrimental to the ozonosphere; it is

hardly combustible.

7.3 Condensate

During cooling on the evaporator the moisture removed

from the air is collected as condensate. In order to avoid

any damage to the switch cabinet and the cooling unit,

the condensate must be discharged.