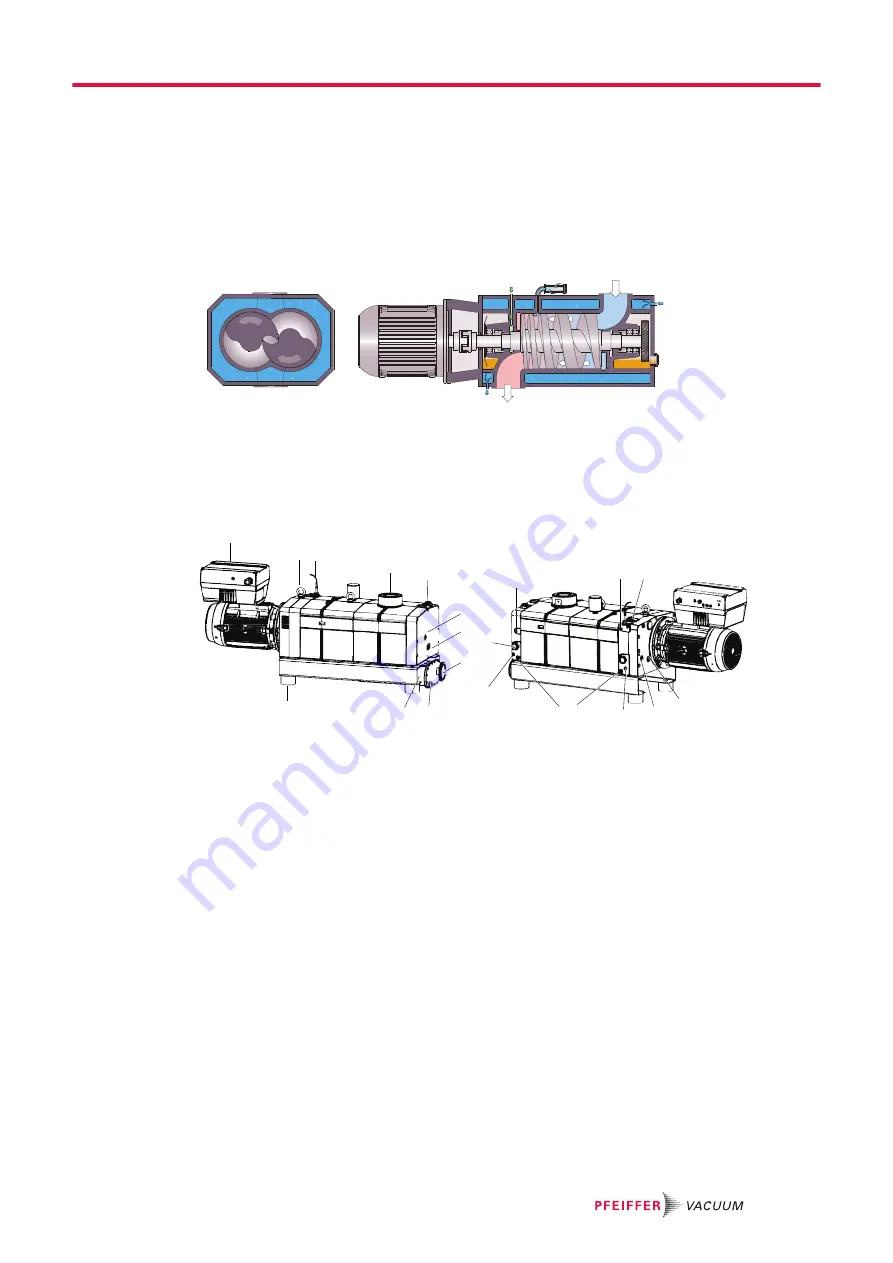

3 Product description

3.1 Function

The HeptaDry screw pumps function according to the double screw-pump principle. Two screw rotors

rotate in the compression chamber. The medium to be pumped is trapped between the individual screw

coils, compacted and transported to the gas outlet. During the compaction process, the two screw rotors

do not come into contact with each other, nor with the suction chamber.

Fig. 2:

Operating principle

Operation of this screw pump is instigated with each occurrence of intake pressure between atmos-

phere and final pressure. Despite contactless operation of the screw pump, no operating fluid, such as

oil or water, is necessary within the working chamber. A gas ballast valve, sealing gas device and/or

silencer can be installed at the gas exhaust, depending on the respective application.

1

2 3

4

5

7

8

9

10

6

12

13

14

15

16

17

18

19

20

11

Fig. 3:

Arrangement of screw pump

1

Frequency converter

11

Cooling water outlet

2

Eye bolt (2x)

12

Filler screw

3

Thermal circuit breaker

13

Magnetic sealing plug

4

Vacuum connection

14

Sealing gas connection

5

Filler screw

15

Drain screw

6

Locking screw for screw rotors

16

Cooling water drain screw

7

Magnetic sealing plug

17

Drain screw

8

Exhaust connection

18

Condensate drain

9

Sight glass (2x)

19

Silencer

10 Cooling water inlet

20

Rubber-metal bumper (4x)

3.1.1 Water cooling

Connection to an external cooling water supply dissipates heat which is generated during compression

of the gas. The cooling water flows through the cooling chambers of the screw pump and absorbs the

heat there.

3.1.2 Temperature monitoring

The switching temperatures are dependent upon the pump size and the type of cooling system. Tem-

perature monitoring prevents overheating and potential blockages in the screw pump.

Product description

17/52