Procedure

1. Unscrew the filler screw.

2. Fill up with lubricant according to the marks on the sight glass.

3. Screw in the filler screw.

4. Check the fill level during operation when running with final pressure.

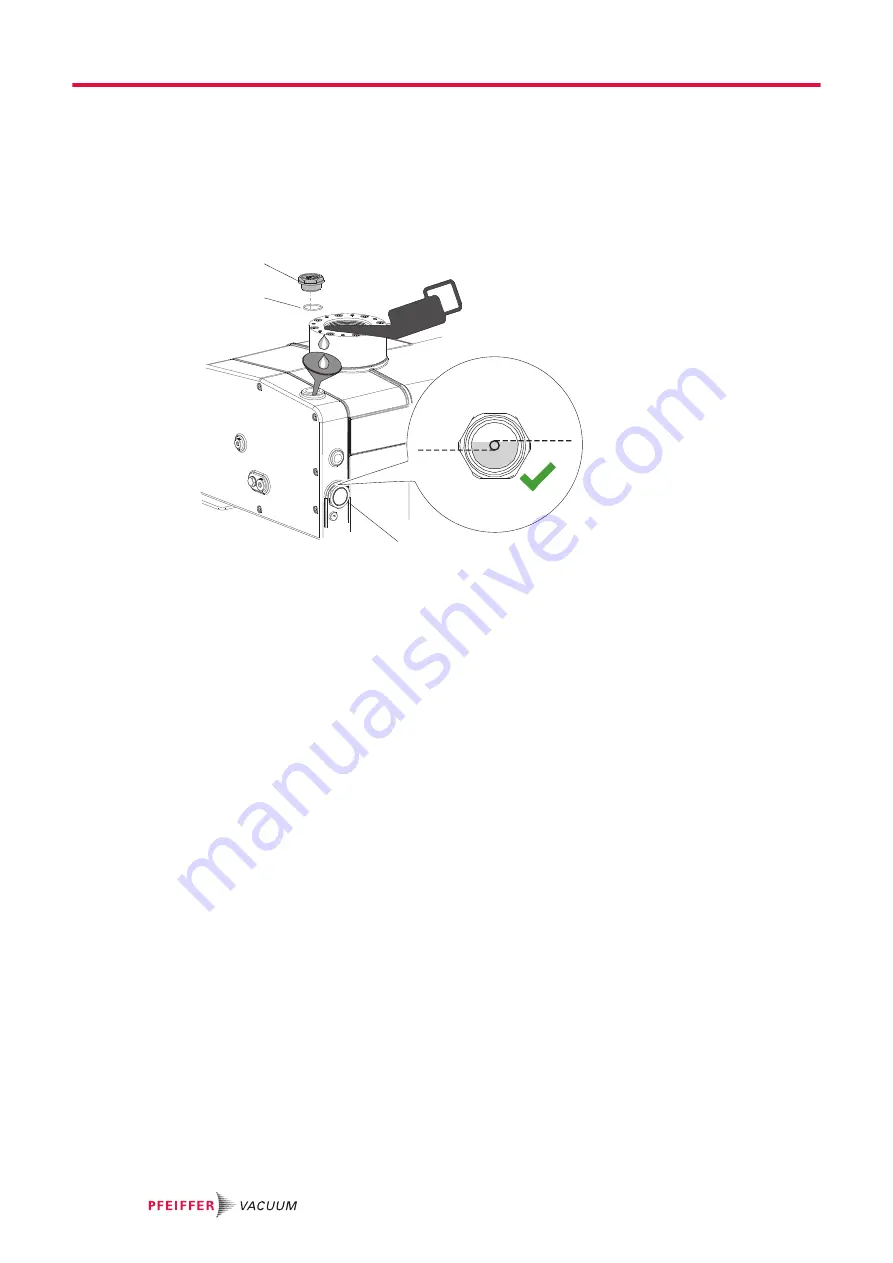

7.4.4 Fillin lubricant on the vacuum side

1

3

2

MAX

MIN

Fig. 16:

Filling lubricant on the vacuum side

1 Filler screw

3

Sight glass

2 O-ring

Procedure

1. Unscrew the filler screw.

2. Fill up with lubricant according to the marks on the sight glass.

3. Screw in the filler screw.

4. Check the fill level during operation when running with final pressure.

7.5 Cleaning the intake strainer

The intake strainer must be cleaned:

● whenever the pumping capacity decreases

● if there is visible contamination

Prerequisites

● Vacuum pump switched off

● Vacuum pump cooled

Required consumables

● Compressed air

Required tool

● Hexagonal wrench,

WAF 8

Maintenance

38/52