Parameter

Cooling water

Feed capacity

8 – 16 l/min

Water pressure

1000 – 6000 hPa

Feed temperature

10 – 30 °C

Necessary differential pressure between flow and return flow

≥ 1000 Pa

Tbl. 6:

Prerequisites for the cooling water

5.5 Connecting sealing gas

Sealing gas protects against contamination at the points of shaft feedthrough when conveying solvents

or reactive gases.

Required consumables

● Nitrogen (N

2

) or another inert gas

Required tool

● Open-end wrench,

WAF 13

4

1

3

2

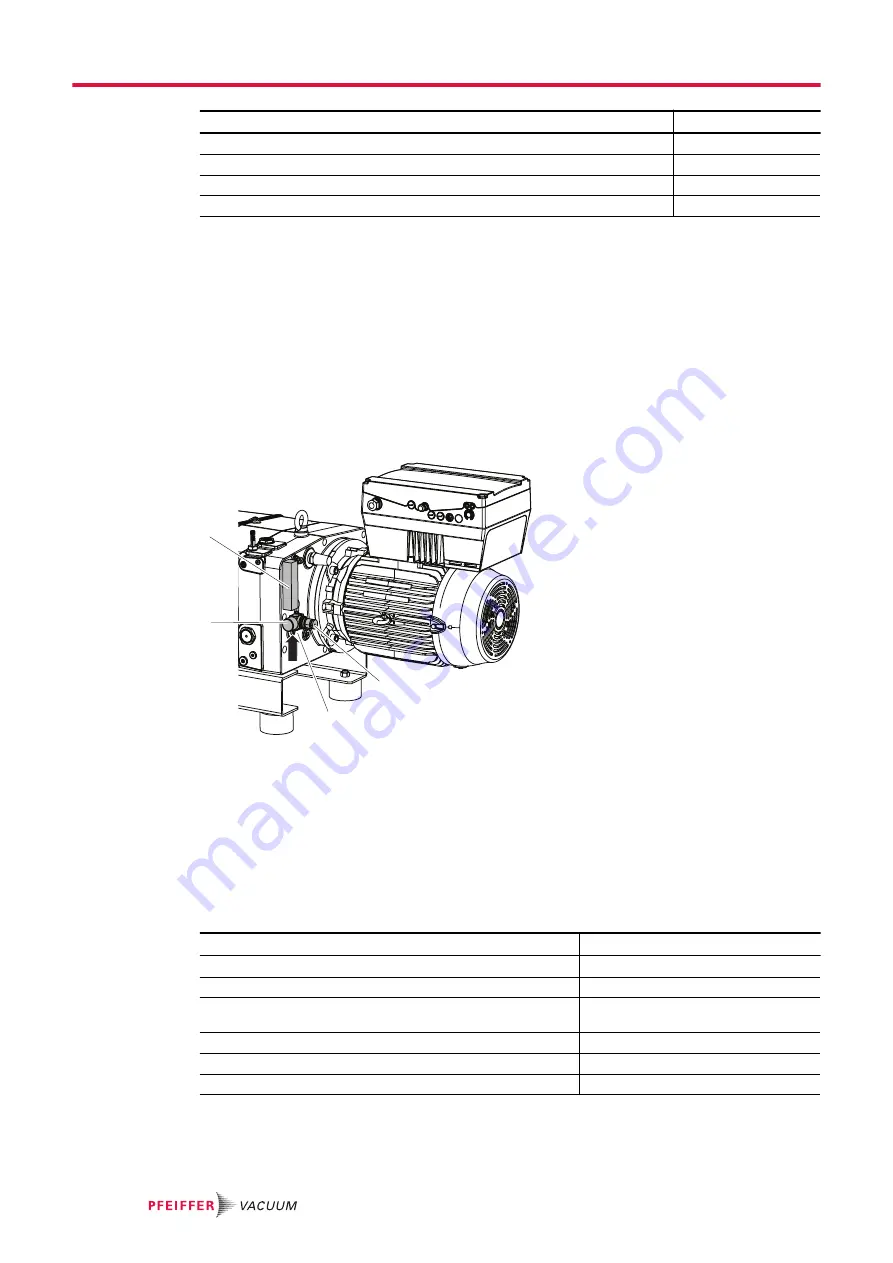

Fig. 7:

Sealing gas connection

1 Inferential meter

3

Sealing gas connection

2 Pressure regulating valve

4

Pressure gauge

Procedure

1. Connect the sealing gas connection to the gas supply.

– Connection size: 1/4" thread, ISO 228-1

– Use the gas cylinder with pressure reducer and inferential meter.

2. Set the sealing gas amount in accordance with the table.

Gas type

Dry nitrogen or air

Gas temperature

0 – 60 °C

Max. gas pressure

13000 hPa

Recommended pressure setting at the pressure regulating

valve

3000 hPa

Filtration

5 μm

Recommended flow rate

15 – 20 SLM

Air quality (for compressed air only)

According to ISO 8573-1, Class 5.4.4.

Tbl. 7:

Requirements for the sealing gas supply

Installation

24/52