24

The Pfeiffer Vacuum parameter set

9.2.5

Set value settings

9.3

Configuring the connections

The electronic drive unit is pre-configured in the factory. Thereby the turbopump is im-

mediately operational with the necessary functions. The connections of the electronic

drive unit can be configured to suit individual requirements using the parameter set.

9.3.1

Accessory connection

Configuration via parameter

[P:035]

,

[P:036]

or

[P:038]

.

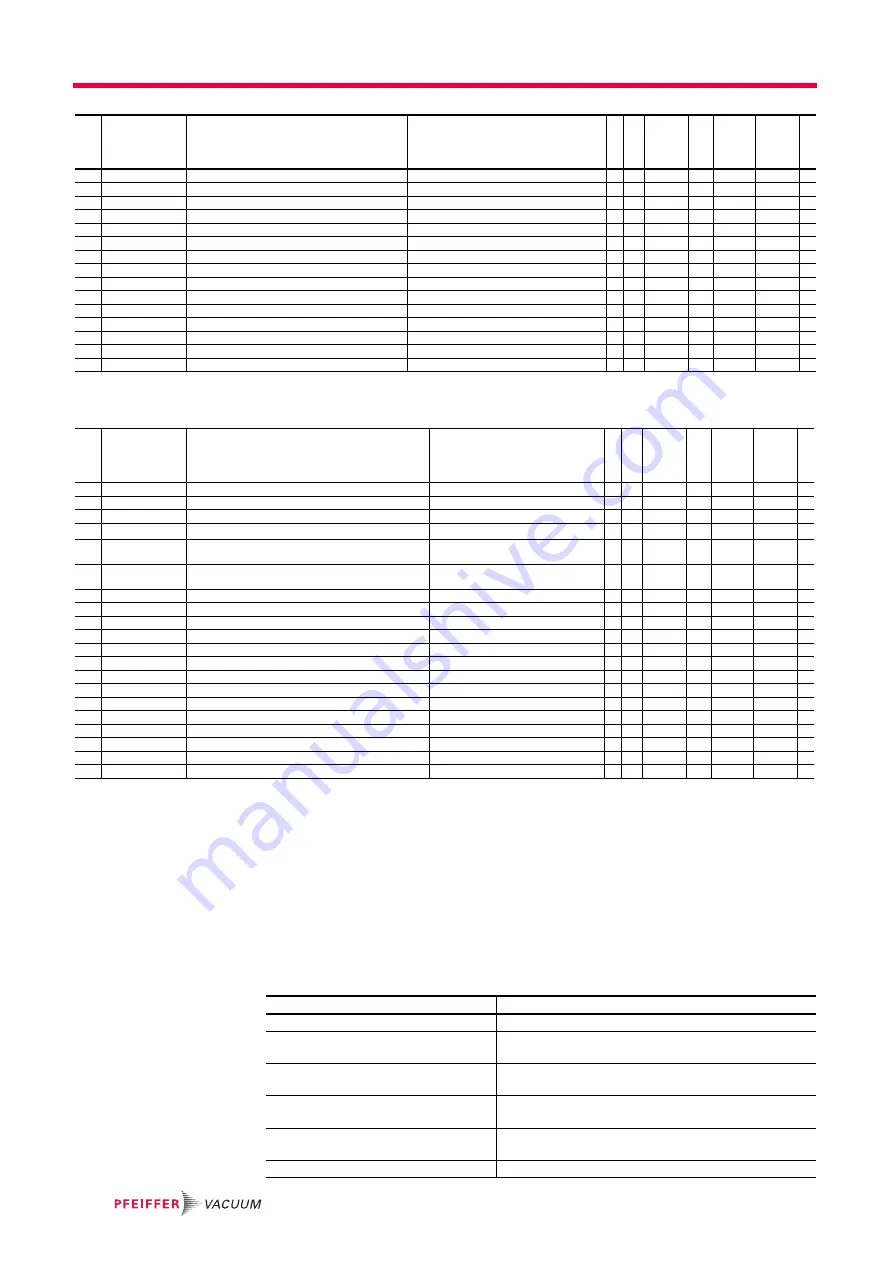

349 ElecName

Name of electronic drive unit

4 R

354 HW Version

Hardware version electronic drive unit

4 R

360 ErrHist1

Error code history, pos. 1

4 R

x

361 ErrHist2

Error code history, pos. 2

4 R

x

362 ErrHist3

Error code history, pos. 3

4 R

x

363 ErrHist4

Error code history, pos. 4

4 R

x

364 ErrHist5

Error code history, pos. 5

4 R

x

365 ErrHist6

Error code history, pos. 6

4 R

x

366 ErrHist7

Error code history, pos. 7

4 R

x

367 ErrHist8

Error code history, pos. 8

4 R

x

368 ErrHist9

Error code history, pos. 9

4 R

x

369 ErrHist10

Error code history, pos. 10

4 R

x

397 SetRotSpd

Set rotation speed (rpm)

1 R

rpm

0

999999

398 ActualSpd

Actual rotation speed (rpm)

1 R

rpm

0

999999

399 NominalSpd

Nominal rotation speed (rpm)

1 R

rpm

0

999999

#

Display

Designation

Functions

Dat

a

t

yp

e

Acc

ess

Unit

min max

default

#

Display

Designation

Functions

Da

ta

ty

pe

Ac

ce

ss

Unit

min max

default

700 RUTimeSVal

Set value run-up time

1 RW min

1

120

12

x

701 SpdSwPt1

Rotation speed switchpoint 1

1 RW %

50

97

80

x

707 SpdSVal

Set value in rot. speed setting mode

2 RW %

50

100

65

x

708 PwrSVal

Set value power consumption

7 RW %

10

100

100

1

x

710 Swoff BKP

Switching off threshold backing pump in intermittend

mode

1 RW W

0

1000

0

x

711 SwOn BKP

Switching on threshold backing pump in intermittend

mode

1 RW W

0

1000

0

x

717 StdbySVal

Set value rotation speed at standby

2 RW %

20

100

66.7

x

719 SpdSwPt2

Rotation speed switchpoint 2

1 RW %

5

97

20

x

720 VentSpd

Venting rot. speed at delayed venting

7 RW %

40

98

50

x

721 VentTime

Venting time at delayed venting

1 RW s

6

3600

3600

x

730 PrsSwPt 1

Pressure switchpoint 1

10 RW hPa

x

732 PrsSwPt 2

Pressure switchpoint 2

10 RW hPa

x

739 PrsSn1Name

Name sensor 1

4 R

740 Pressure 1

Pressure value 1

10 RW hPa

x

742 PrsCorrPi 1

Correction factor 1

2 RW

x

749 PrsSn2Name

Name sensor 2

4 R

750 Pressure 2

Pressure value 2

10 RW hPa

x

752 PrsCorrPi 2

Correction factor 2

2 RW

x

777 NomSpdConf

Nominal rotation speed confirmation

1 RW Hz

0

1500

0

x

797 RS485Adr

RS-485 device address

1 RW

1

255

1

x

1. depending on the pump type

Option

Description

0 = Fan (continous operation)

Control via parameter Pumping station

1 = Venting valve, normally closed

Control via parameter Enable venting, when using a venting

valve which is normally closed.

2 = Heating

Control via parameters Heating and Rotation speed switch-

pont attained

3 = Backing pump

Control via parameters Pumping station and operation

mode backing pump

4 = Fan (temperature controlled)

Control via parameter Pumping station and temperature

thresholds

5 = Sealing gas

Control via parameters Pumping station and Sealing gas