Mixing pump RITMO L / RITMO M Overview - Operation

Table of Contents

4

2016-02-17

19.2 Flowability / Flow characteristics

RITMO M ........................................... 26

20 Mortar pressure gauge ................................. 27

21 Safety rules.................................................... 27

22 Transport, packing and storage .................. 27

22.1 Safety instructions for transport ........... 27

22.2 Tighten the nut before beginning the

transport ............................................. 28

22.3 Transport inspection............................. 28

22.4 Transport in individual parts ................. 29

22.5 Transport with passenger car .............. 29

22.6 Transport of already running machine . 29

23 Packaging ...................................................... 30

24 Operation ....................................................... 30

24.1 Safety ................................................... 30

25 Preparing the machine ................................. 31

25.1 Connecting the power supply 230 V .... 32

25.2 Connecting the water supply ................ 32

25.3 Connection of water from water tank ... 33

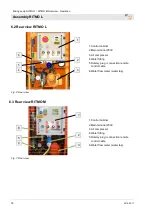

26 Switching on RITMO L .................................. 34

26.1 Putting RITMO L into operation ........... 34

26.2 Presetting the water flow rate. ............. 34

27 Switching on RITMO M ................................. 35

27.1 Putting RITMO M into operation .......... 35

27.2 Presetting the water flow rate .............. 35

28 Mortar pressure gauge ................................. 36

28.1 Hazardous dusts .................................. 36

29 Feeding dry material to the machine .......... 36

30 Monitoring the machine ............................... 37

31 Putting the machine into operation ............ 37

31.1 Check consistency of mortar ................ 37

31.2 Start RITMO L in “flying mode” ............ 37

31.3 Start RITMO M in “flying mode” ........... 38

32 Potentiometer ................................................ 38

33 Mortar hoses ................................................. 39

33.1 Prepare mortar hoses .......................... 39

33.2 Connect mortar hose ........................... 39

34 Compressed air supply ................................ 40

34.1 Connect and fix the air ......................... 40

34.2 Connecting the spraying gun ............... 40

34.3 Switch on air compressor .................... 40

34.4 Switching on vibrating unit (RITMO L) . 40

35 Apply mortar ................................................. 41

35.1 Open the air tap at the spraying gun ... 41

35.2 Interruption of work .............................. 42

35.3 In case of longer interruption of

work/break ......................................... 42

35.4 Switch off air compressor .................... 43

36 Remote control ............................................. 43

36.1 Working with the remote control .......... 43

37 Process pasty material ................................ 43

37.1 Recommended accessories for pasty

material .............................................. 43

37.2 Process pasty material ........................ 44

38 Stopping in case of emergency RITMO L /

RITMO M ..................................................... 44

38.1 Emergency-stop switch........................ 44

39 Action in case of water outage ................... 45

40 Action in case of power cut......................... 45

40.1 Main switch to position “0” ................... 45

40.2 Relieve mortar pressure ...................... 46

40.3 Switching on RITMO L again after

power failure ...................................... 46

40.4 Switching on RITMO M again after

power failure ...................................... 47

41 Work on troubleshooting ............................. 47

41.1 Reaction in the event of faults ............. 47

41.2 Fault displays ....................................... 48

41.3 Faults ................................................... 48

41.4 Safety ................................................... 48

41.5 Table of faults ...................................... 48

41.6 Table of faults ...................................... 49

42 Conveyor stands still / clogging ................. 51