Mixing pump RITMO L / RITMO M Overview - Operation

Removal of clogging in hoses

52

2016-02-17

42.3 Earlier damage to the mortar hose

NOTE!

If in the event of a machine fault by clogging the pressure in

the mortar hose exceeds 60 bar, even only temporarily,

replacement of the mortar hose is recommended as there

might be damage in the hose that is not externally visible.

43 Removal of clogging in hoses

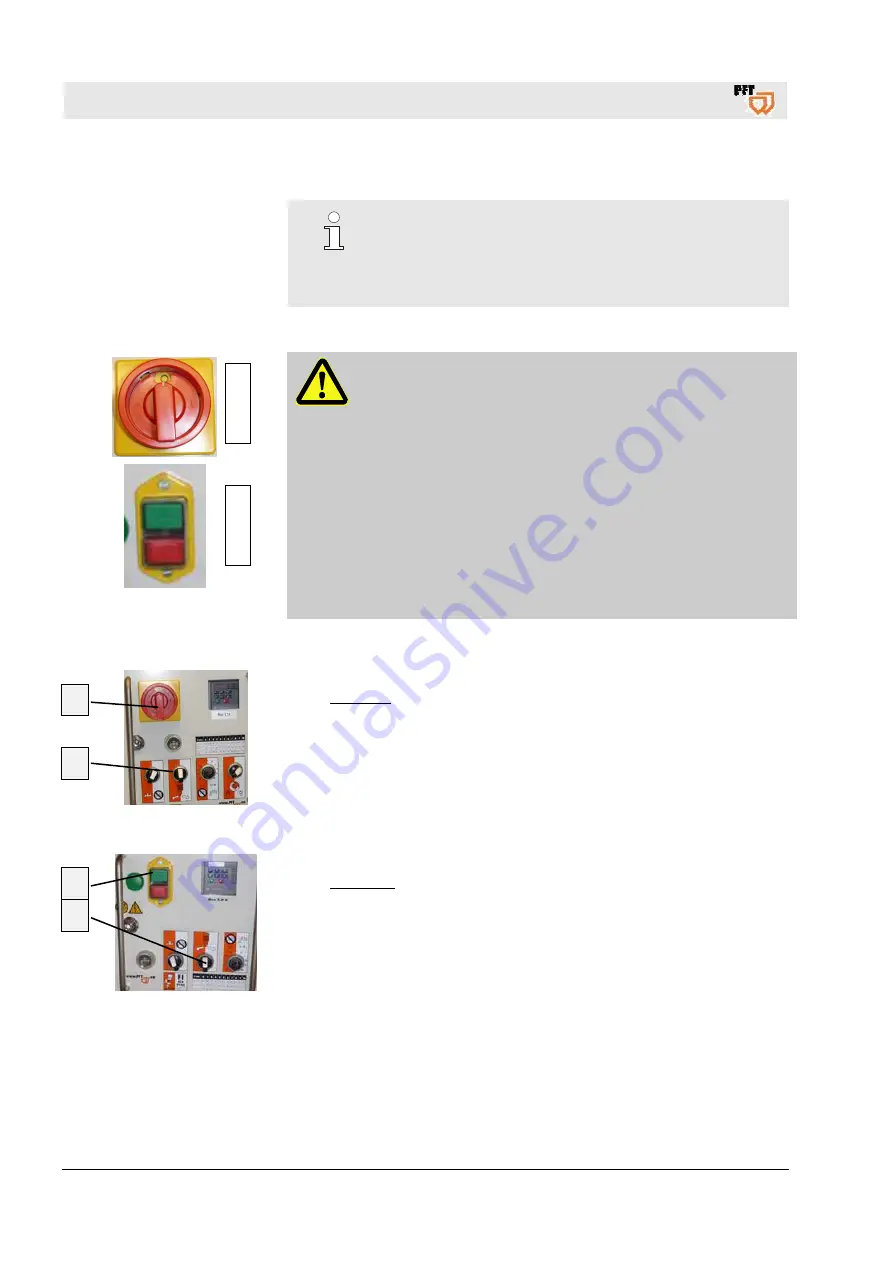

Fig. 79: Switching off

DANGER!

Danger from discharged material!

Never loosen the hose couplings till there is no supply

pressure at all! Material to be conveyed can be discharged

under pressure and cause injuries particularly to the eyes.

Persons commissioned with the cleaning of clogged

hoses have to wear personal protective equipment

(protective goggles, gloves) for safety reasons, and to

position themselves in such a way that they cannot be

hit by discharged material. Other persons have to clear

the area.

43.1 Run the pump motor in the backward mode

Fig. 80: Backward run RITMO L

RITMO L

1. Switch main switch (1) to position “I”.

2. Turn selector switch (2) direction of rotation of the pump motor

anti-clockwise, until the pressure at the mortar pressure gauge

has dropped to “0 bar”.

Fig. 81: Backward run RITMO M

RITMO M

3. Press the green push button (3) operation “ON”.

4. Turn selector switch (4) direction of rotation of the pump motor

anti-clockwise, until the pressure at the mortar pressure gauge

has dropped to “0 bar”.

R

IT

M

O

L

R

IT

M

O

M

1

2

3

4