Mixing pump RITMO L / RITMO M Overview - Operation

Removal of clogging in hoses

2016-02-17

53

43.2 Blockage cannot be cleared

2

1

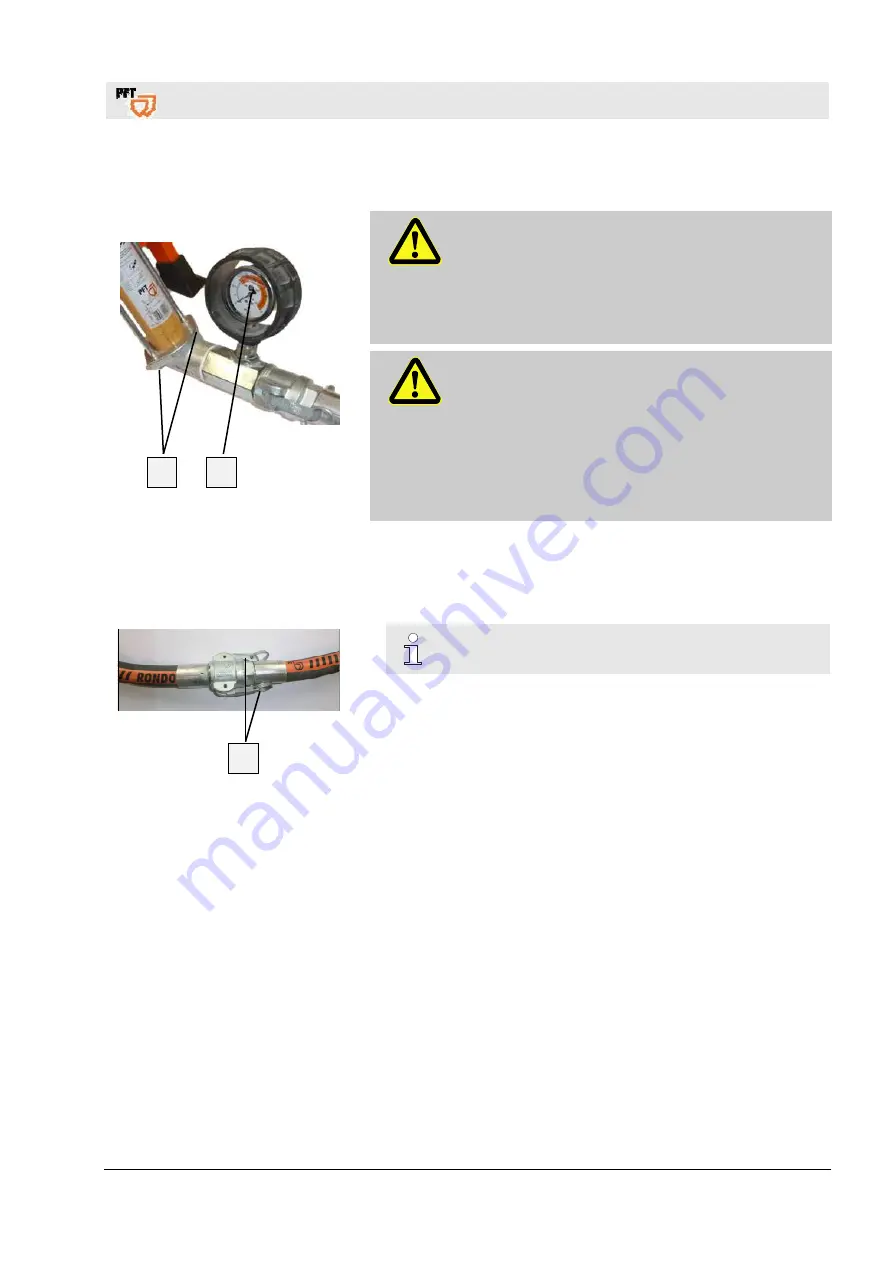

Fig. 82: Check mortar pressure

DANGER!

Overpressure on the machine!

When opening machine parts they can open in an

uncontrolled manner and injure the operator.

Open the mortar hoses only when the pressure at

the mortar pressure gauge (1) has dropped to "0

bar".

DANGER!

Risk of injury from discharged mortar!

Discharged mortar may lead to injuries to eyes and

face.

Therefore:

Always wear protective goggles.

Always position yourself in such a way that you

are not hit by the mortar being discharged.

1. Slightly loosen both screws (2) at the tie rod so that the remaining

pressure can escape completely.

2. As soon as the pressure is down to “0 bar”, tighten the screws (2)

again.

3

Fig. 83: Loosen coupling

NOTE!

Clean mortar hoses immediately

1. Cover coupling connections with tear-proof film.

2. Loosen cam leaver (3) and hose connections.

3. Dislodge the blockage by tapping or shaking at the place where

the blockage is located.

4. If required, insert a rinsing hose into the mortar hose and flush

out the material (PFT rinsing hose art. no. 00113856).