CAYMAN Part 2 Overview – Operation - Spare parts lists

Work on troubleshooting

40

2017-03-22

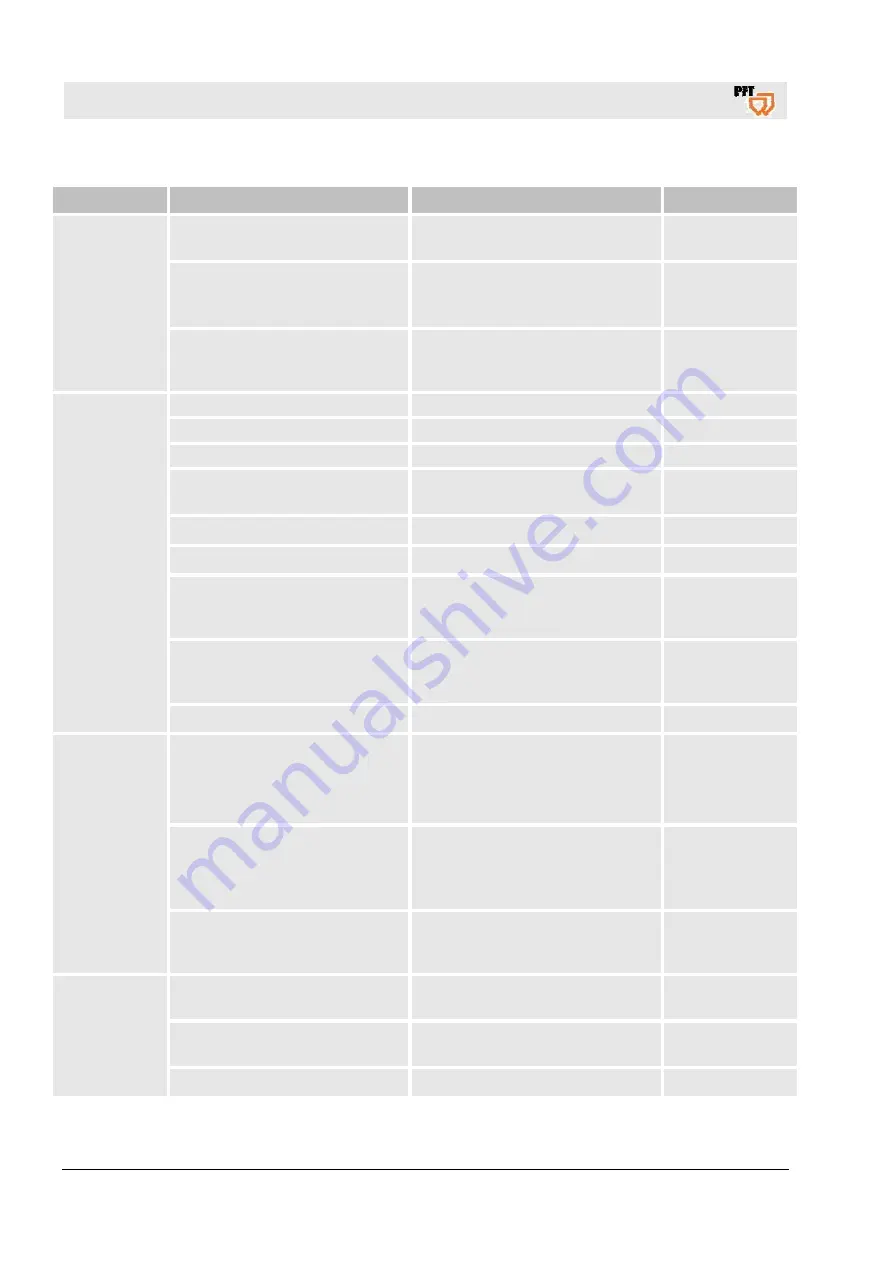

34.6 Table of faults

Fault

Possible cause

Solution

Rectification by

Machine does

not start:

Water

Control lamp

“no water

pressure”

No water

Pressure switch or solenoid valve

defective

Service engineer

Water pressure too low - pressure

gauge shows less than 2 bar

Check water supply line, clean

strainer screen, supply line cross

section at least ¾ inch.

Operator

Water pressure too low

Check water supply line. Lay

additional supply line. Water

container as buffer.

Operator

Machine does

not start:

Current

Main switch not activated

Activate main switch

Operator

Power supply not in order

Repair power supply

Service engineer

Protection switch was triggered

Reset RCCB

Service engineer

Motor protection switch triggered

Turn motor protection switch in

control box to position 1

Service engineer

“Operating button On” not pressed Press “Operating button On”

Operator

Press “EMERGENCY-STOP”

switch

Release “EMERGENCY-STOP”

switch

Operator

“Manual/automatic selector switch

was not in the middle position

while switching on.

Bring the selector switch in the

middle position and switch on the

control again.

Operator

Control lamp “Change direction of

rotation” lights up.

Change the direction of rotation at

the main switch. Check fuse or

supply line

Operator

Micro fuses on the transformer

faulty

Replace micro fuses

Service engineer

Machine does

not start:

Material:

Too much dried material in the

material container. Possible

tunnel formation

Caution:

Main switch

OFF

-

Disconnect the main power cable.

Empty the material container.Re-

start machine.

Operator

Dried out material clogs up the

pump unit (rotor/stator)

Caution:

Main switch

OFF

-

Disconnect the main power cable.

Disassemble, clean and re-install

the pump.

Operator

Excessively dry material in pump

part

Caution:

Main switch

OFF

-

Disconnect the main power cable.

Clean the hopper

Operator

Machine does

not start:

“No Material”

Control is on “Run machine on

empty”

Bring switch “Run machine on

empty” to zero position

Operator

Machine is started up with “Mixer

container empty”

Position manual / automatic

selector switch on manual mode

Operator

Dry material sensor faulty

Replace dry material sensor

Service engineer

Summary of Contents for 00 24 88 94

Page 83: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 2017 03 22 83 ...

Page 84: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 84 2017 03 22 ...

Page 85: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 2017 03 22 85 ...

Page 86: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 86 2017 03 22 ...

Page 87: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 2017 03 22 87 ...

Page 88: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 88 2017 03 22 ...

Page 89: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 2017 03 22 89 ...

Page 90: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 90 2017 03 22 ...

Page 91: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 2017 03 22 91 ...

Page 93: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 2017 03 22 93 ...

Page 94: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 94 2017 03 22 ...

Page 95: ...CAYMAN Part 2 Overview Operation Spare parts lists Circuit diagrams 2017 03 22 95 ...

Page 99: ...CAYMAN Part 2 Overview Operation Spare parts lists 2017 03 22 99 ...