PFT ZP 3 L MULTIMIX Overview – Operation – Spare Parts Lists

Clearing hose blockages

40

2016-07-04

35.8 Pre-existing damage on mortar hose

NOTE!

Should a machine malfunction due to a blockage

cause the pressure in the mortar hose to only

briefly exceed 60 bar replacement of the mortar

hose is recommended, since unseen damage to

the hose cannot be ruled out.

36 Clearing hose blockages

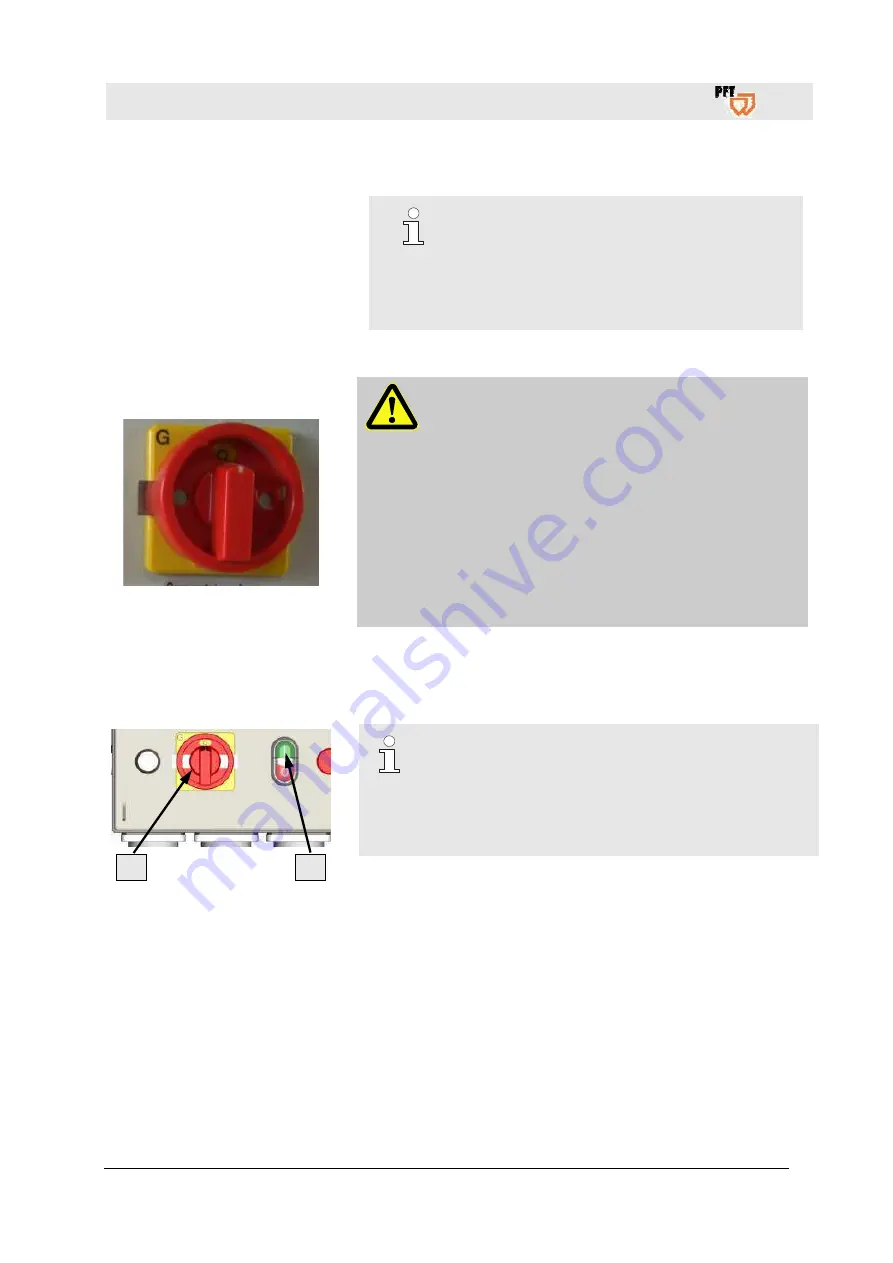

Fig. 61: Switching off

DANGER!

Danger due to escaping material!

Never detach hose couplings if the feed pressure

has not been released. The conveyed material can

escape under pressure and lead to serious injuries,

especially eye injuries.

In accordance

with the accident prevention

regulations of the Builder’s Guild, all personnel

clearing blockages should wear personal safety

equipment (safety goggles, protective gloves) and

position themselves so as not to be hit by escaping

material. Other persons are not permitted in the

vicinity.

Turn the main reversing switch to position “0”.

36.1 Reversing the direction of rotation of the pump motor in the event of

clogged hoses

1

2

Fig. 62: Changing the direction of

rotation

NOTE!

The main reversing switch is locked in the zero position

by pushing the selection switch (1) to the left or right.

This defines the direction of rotation. If the switch is set

to the left, the switch can be reset to zero but is blocked

for the right-side position.

1. Press the green push button (2) to switch the control voltage

“ON”