PFT ZP 3 L MULTIMIX Overview – Operation – Spare Parts Lists

Cleaning

2016-07-04

41

36.2 Observe the mortar pressure shown by the mortar pressure gauge!

2

Fig. 63: Mortar pressure at 0 bar

1. Let pump motor run in reverse (1) briefly until the pressure on the

mortar pressure gauge has fallen to “0 bar”.

2. Switch off the ZP 3 L using the main reversing switch.

3. Push the direction plate on the main reversing switch back to its

starting position.

DANGER!

Overpressure on the machine!

When opening machine components, these can fly

open in an uncontrolled manner and injure the

operator.

– Only open the mortar hoses if the pressure has

fallen to 0 bar.

36.3 Detaching coupling connections

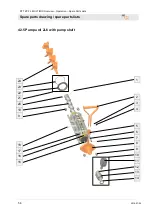

Fig. 64: Hose blockages

1. Cover coupling connections with tear-resistant film.

2. Undo both nuts (1) on the pressure flange (

fig. 60

) slightly to

ensure the residual pressure can escape.

3. Loosen the hose coupling and clean the mortar hose

immediately.

3. Knock or shake out the blockage.

4. If necessary, rinse out the material hoses using a PFT rinsing

hose (item number 00113856) and then wet with wallpaper

paste again.

5. Finally, reconnect the hoses to each other.

6. Tighten the nuts (1) and pressure flange (

fig. 60

) again.

37 Cleaning

37.1 Securing against restarting

Fig. 65: Cleaning

Cleaning:

Before prolonged interruptions to work and after the end of daily

work, the ZP 3 L conveying pump must be cleaned thoroughly.