SWING M delivery pump / Part 2 Overview, operation and service

Operation

5.6

Applying mortar

WARNING

Danger of injury from discharged mortar!

Discharged mortar may lead to injuries to eyes and face.

Never look into the spray gun.

Always wear protective goggles.

Always position yourself in such a way that you are not

hit by the mortar being discharged.

The possible conveying distance depends mainly on the

flowability of the mortar. Heavy, sharp-edged mortar has

poor flow characteristics. Fluid materials have good flow

characteristics.

If an operating pressure of 20 bar is exceeded, the

hose length must be shortened or the hose thickness

increased.

5.6.1

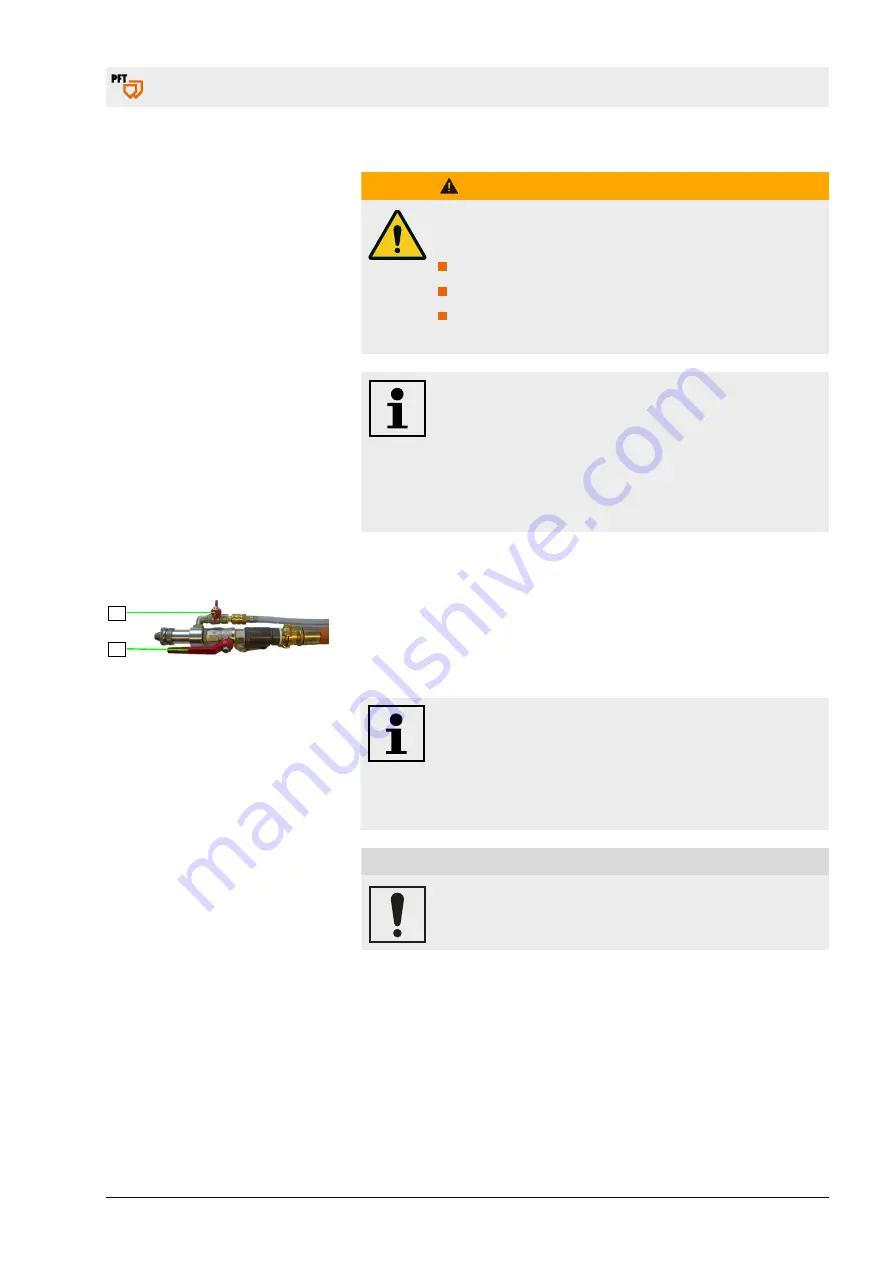

Open the valves on the spray gun

2

1

Figure 33: Open taps

1. Point the spray gun toward the wall to be plastered.

2. Check that no-one is in the spray gun range.

3. Open the air tap (1) on the spray gun.

4. Open the ball valve for mortar (2) on the spray gun.

The correct mortar consistency is reached, if the mate-

rial mixes on the surface to be sprayed (we recommend

application on wall surfaces from top to bottom). Uniform

mixing and spraying cannot be ensured if the amount

of water is insufficient. This can clog the hoses and the

pumping components are then subjected to greater wear.

NOTE

When working with pressure control, the machine starts

automatically as soon as the air tap (1) is opened and

stops again as soon as the air tap is closed.

page 29 / 52